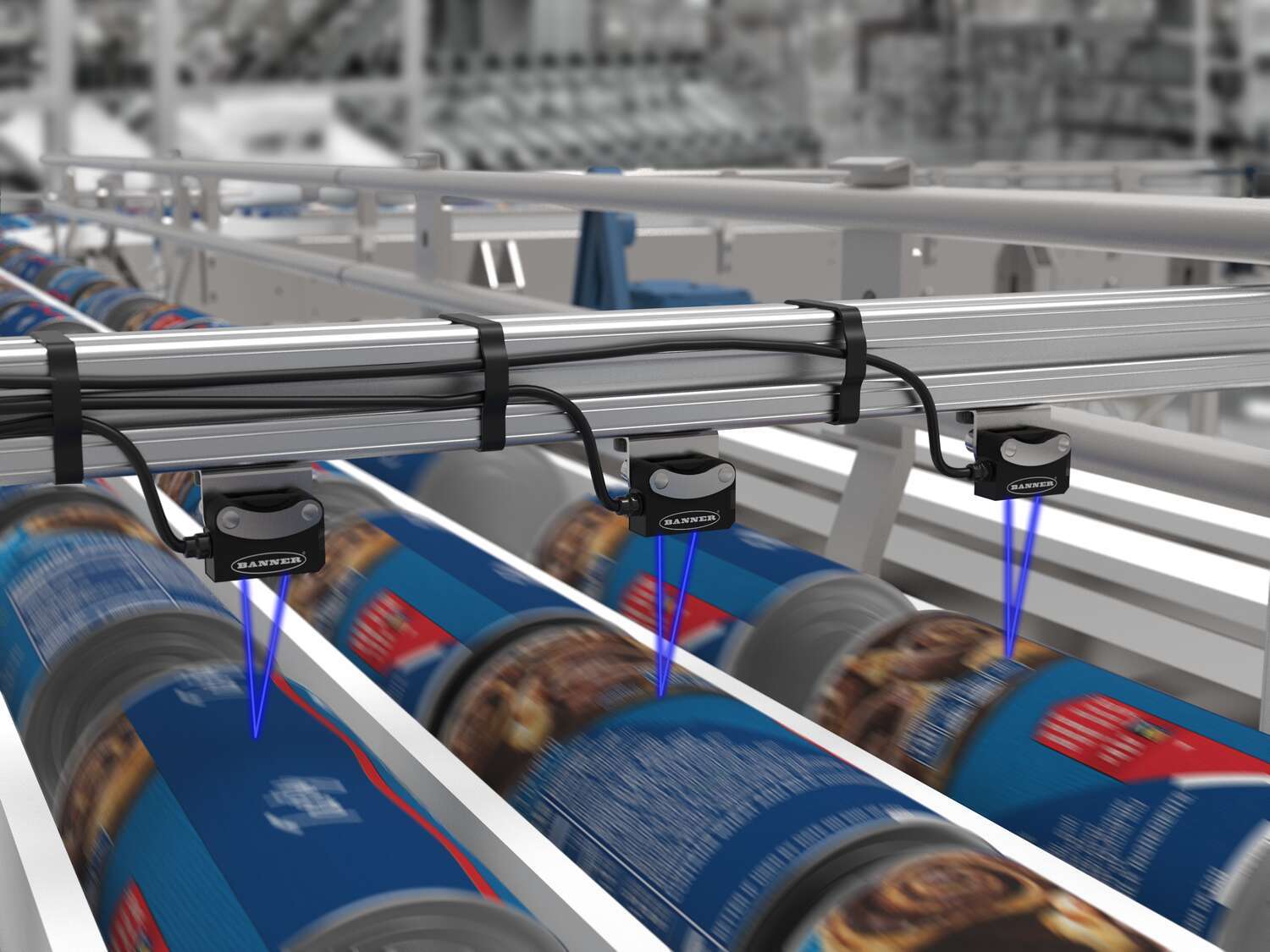

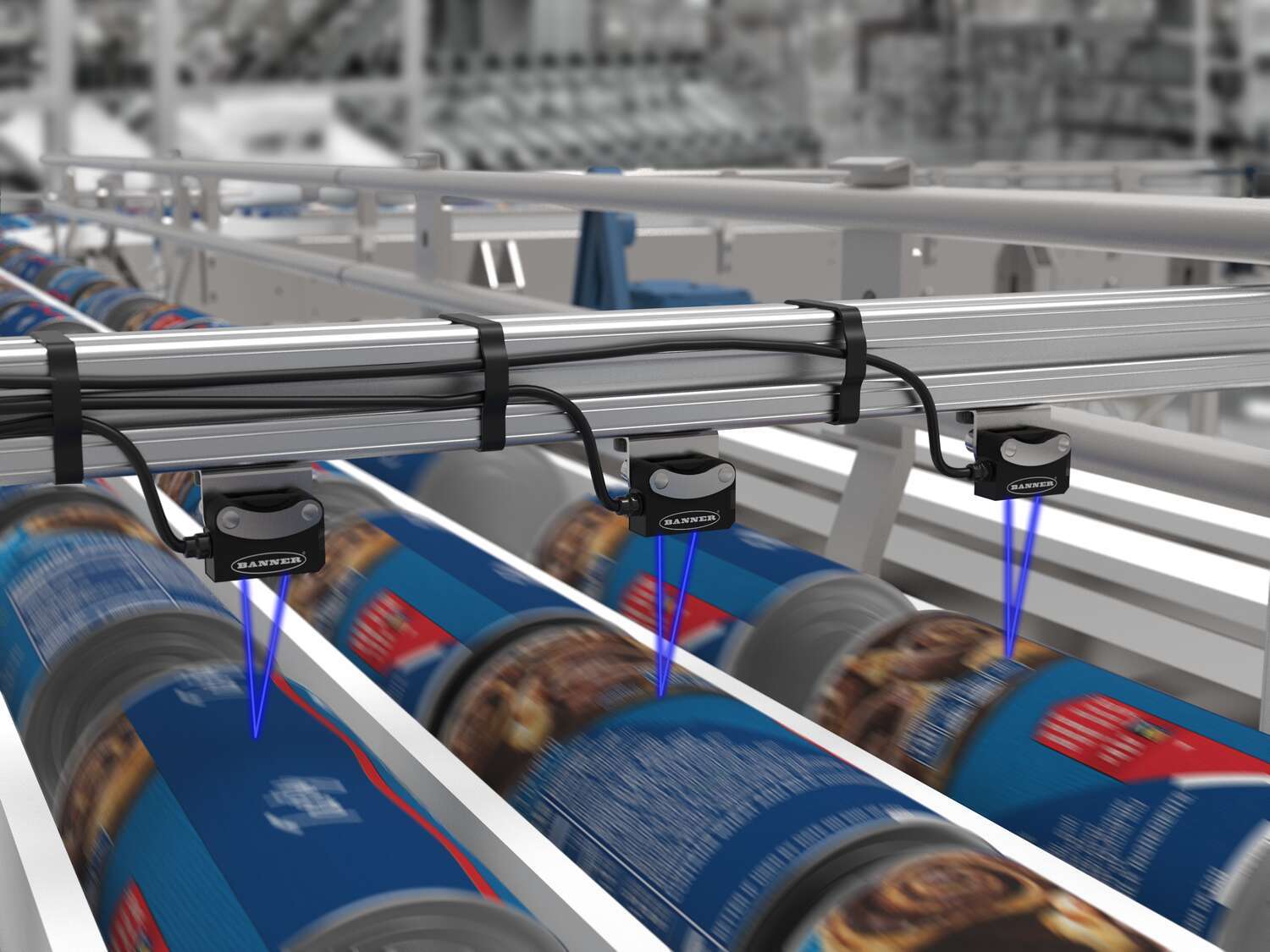

Detecting Refrigerated Breakfast Rolls on a Multi-Lane Conveyor

Application: Index packaged breakfast rolls for case packer machine

Challenges: Dark multi-colored labels with irregularly shaped packaging

Solution: VS8 Miniature Sensor with blue LED

Benefits: Small spot size, high excess-gain, adjustable sensing range

Case packers run a variety of product types, sizes, and packages and robust sensing solutions are critical for accuracy, productivity, and cost savings. Primary packaging stations seal the refrigerated food, such as rolls or biscuits, inside pressurized cans. Once the pastries have gone through all primary packaging machines they move onto secondary packaging to prepare for distribution. Secondary packaging equipment is fast-paced, and any delays impact the overall performance and throughput.

Once the rolls are packaged and labeled they move on to the case packer where a predetermined quantity is placed into a box and later palletized for shipping. Accurate sensing of the packaged rolls is necessary to ensure each case is filled with the correct amount of product. A multi-lane conveyor collates the product into specific quantities which can be robotically picked or mechanically loaded into its case. Robust and detailed sensing allows for precise leading-edge detection and increased packaging speeds, increasing overall equipment effectiveness.

Blue LED for Objects with Low Reflectivity

Food packaging OEM’s are constantly facing challenging sensing applications due to continuous changes in packaging design. In such a highly competitive market, companies are consistently vying for consumer’s attention with shiny multi-colored packages that stand out in the grocery aisle.

A manufacturer was having issues reliably sensing breakfast rolls packaged in dark blue and multi-color packaging. Under red LED lights, blue labels very closely resemble black and have little reflectivity which makes detection difficult with standard red LED sensors. These sensors also experienced erratic and chattering outputs on color transitions on the label.

Banner Engineering’s VS8 Miniature Photoelectric Sensor with blue LED is a unique problem-solver. The blue LED works well with low-reflectivity objects and multicolored packaging by creating more contrast for stable sensing. The VS8’s small spot size minimizes the effects of color transitions as the package passes by the sensor. The blue LED with small spot size alleviated the chattering output and sensing problems and created a more reliable system for the customer.

Small sensors with shorter sensing ranges are ideal as more machine builders compress mechanical features into tight spaces. The VS8 is miniature in size, measuring just 21 mm x 14 mm x 8 mm, but remains a high-quality, versatile sensor that does not compromise performance in crowded working spaces with limited mounting options. The brackets are adjustable up to 15 degrees in either direction for ease-of-use and flexibility. The VS8 is CE, UL, and ECOLAB certified and rated to IP67. Setup is easy with remote teach and push buttons with lock-out functionality and background suppression to ignore anything beyond the target, such as a conveyor belt.