What is Excess Gain and How to Use It to Choose a Sensor

Understanding what excess gain is—and how much your application requires—is an important part of choosing the right sensor technology. This article explains what excess gain is, how it is measured, and general guidelines for how much excess gain is needed for sensing applications in various industrial environments.

What is Excess Gain?

Excess gain is a measure of the minumum light energy needed for reliable sensor operation.

The light signal that your sensor emits is factory-calibrated to a certain level of performance. However, contaminants in the sensing environment such as dirt, dust, smoke, and moisture, can cause signal attenuation. Excess gain may be seen as the extra sensing energy available to overcome this attenuation.

Measuring Excess Gain

Excess gain can be expressed as the following formula.

Excess gain = light energy falling on receiver element / sensor’s amplifier threshold.

The threshold is the level of sensing energy required by the sensor's amplifier to cause the sensor's output to switch "on" or "off."

Why Excess Gain is Important for Optical Sensors

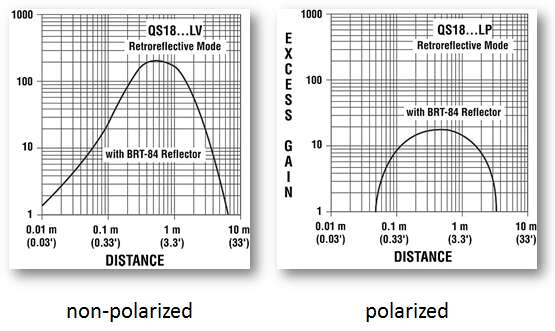

An excess gain curve, an important part of every photoelectric sensor specification, is plotted on an x/y axis. It shows the excess gain available for a particular sensor or sensing system, as a function of distance. Excess gain curves are plotted for conditions of perfectly clean air and maximum receiver gain.

Important Assumptions

There are a few assumptions about using excess gain to optimize the sensing function in your application.

- Use as high an excess gain setting as possible, without compromising target detection. In most sensing situations, excess gain correlates directly to sensing reliability.

- Choose oa sensor that will give you the optimal excess gain for your application.

Image: Example of excess gain curves for the QS18 photoelectric sensor with retroreflective mode.

How to Use Excess Gain to Choose the Proper Sensor Technology

| Excess Gain (EG) | General Conditions |

|---|---|

| Excess Gain (EG) 1.5x | General Conditions Clean air: No dirt on lenses or reflectors. |

| Excess Gain (EG) 5x | General Conditions Slightly dirty: Slight buildup of dust, dirt, etc. on lenses or reflectors. Lenses are cleaned regularly. |

| Excess Gain (EG) 10x | General Conditions Moderately dirty: Obvious contamination on lenses or reflectors. |

| Excess Gain (EG) 50x | General Conditions Very dirty: Heavy contamination on lenses. Heavy fog, mist, dust, smoke, or oil film. Minimal cleaning of lenses. |

If the general conditions of a sensing area are known, the excess gain levels that follow may be used as guidelines for assuring that the sensor’s light energy will not be entirely lost to attenuation.

These guidelines include a safety factor for subtle sensing variables such as gradual sensor misalignment and small changes in the sensing environment.

Clean Air - 1.5x Excess Gain (EG)

For a perfectly clean operating environment, an excess gain of 1.5x (50% more energy than the minimum needed for operation) is suggested. Some environments that have "clean air" are those found in the semiconductor or pharmaceutical industries. In these environments, no dirt builds up on the sensor lenses or retroreflectors.

Slightly Dirty - 5x EG

An office or a clean factory might be characterized as a "slightly dirty" environment. This means sensor lenses or retroreflectors may experience a slight build-up of dust, dirt, oil, or moisture. Lenses are cleaned on a regular schedule. In a "slightly dirty" environment, the excess gain should be 5 times more than what is minimally required for sensor operation.

Moderately Dirty – 10x EG

In a "moderately dirty" environment, obvious contamination can be seen on lenses or retroreflectors. These environments are also likely to have periodic washdowns. "Moderately dirty" environments can be found in heavy industry, food processing, or the automotive industry. For such environments, Banner recommends an excess gain 10 times more than what is minimally required.

Very Dirty – 50x EG

Some environments like those found in foundries, mining operations, tile ovens, and outdoors are considered "very dirty." This is because lenses and retroreflectors become heavily contaminated, and are subject to minimal cleaning. There may be heavy fog, mist, dust, smoke, or oil film in the environment.

Banner recommends 50 times more excess gain in these types of environments. However, it is important to note that at excess gains above 50x, sensors will begin to see through paper or other materials with a similar optical density.