Primary Food Packaging

Banner offers IP68 and 69 rated products and solutions designed specifically to perform reliably in harsh conditions and withstand the environmental challenges common to primary packaging areas in the food processing industry.

Generating greater yields while lowering costs is a must. Regulating product flow; detecting challenging targets of all shapes, colors, and finishes; and operating in harsh washdown environments require extensive industry expertise. That’s why competitive companies choose Banner Engineering to help improve efficiency, flexibility, and scalability while maintaining product consistency and quality.

Whether processing raw produce and meat, baking, or freezing, Banner’s industry-proven solutions help minimize downtime and enhance workplace safety.

As the critical link between growers and consumers, food manufacturers around the world turn to Banner technology to solve their automation challenges. With expertise in track-and-trace systems, measurement and inspection, quality control, and more, Banner is helping companies be nimbler and more adaptive to industry change.

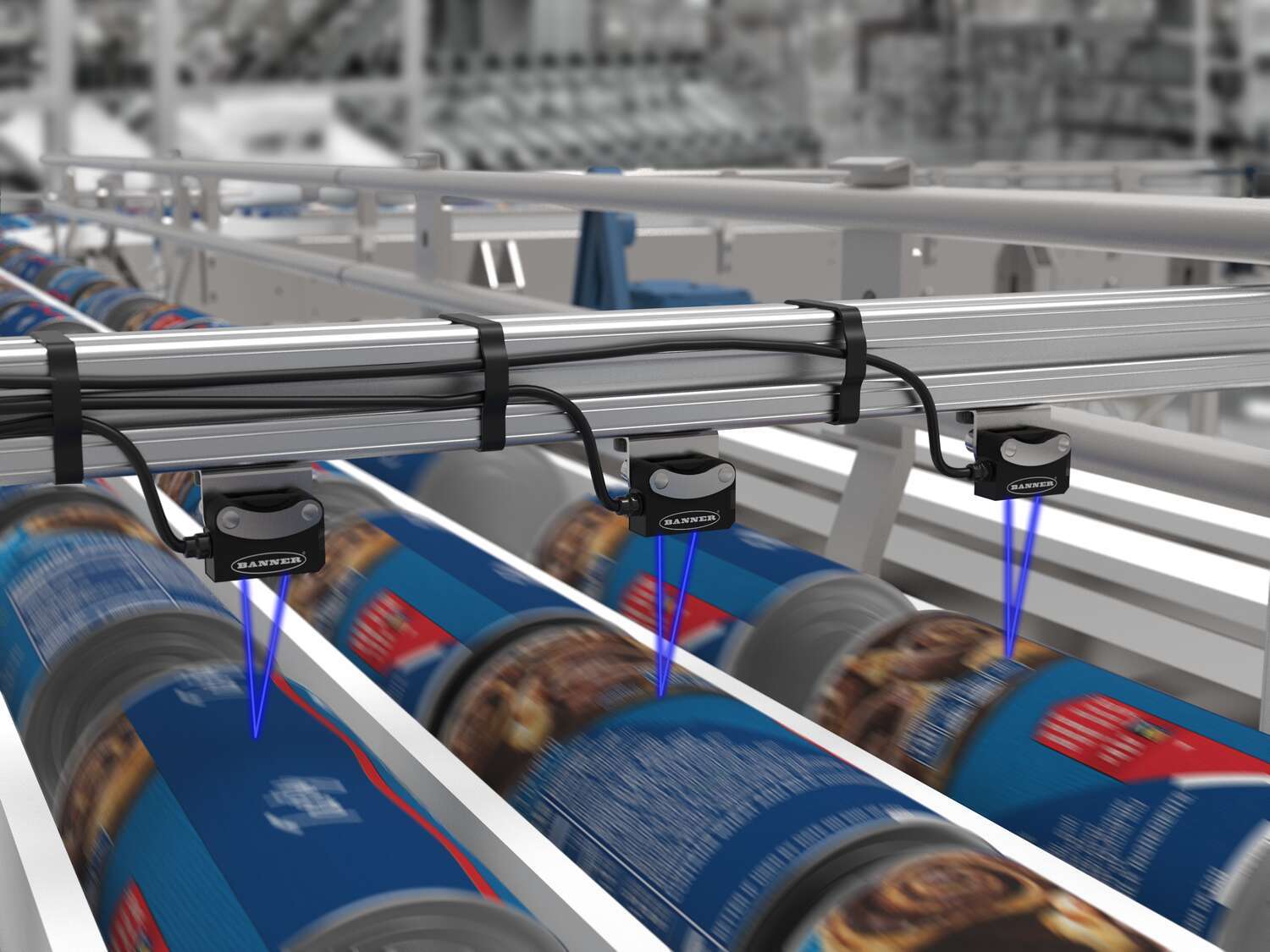

We are experts in automation technologies, offering a comprehensive catalog of more than 10,000 products, including sensors and measuring devices; lighting, indicators, and displays; connectivity technology; condition monitoring solutions; machine safety products; industrial wireless systems; remote I/O, barcode scanners, and machine vision. By listening to customers and engineering solutions that remove production constraints, Banner is helping them drive efficiencies, improve output and system accuracy, and reduce errors and expenses.

Tracking tray levels on a denester machine ensures that product is replenished in a timely manner and does not affect production.

Learn More

Banner’s LTF Series Laser Measurement Sensor features high excess gain, superior signal control and automatic adaptive laser power control. These features enable reliable detection of the chewing gum from up to 12 meters away, regardless of color or reflective surfaces inside the hopper.

Learn More

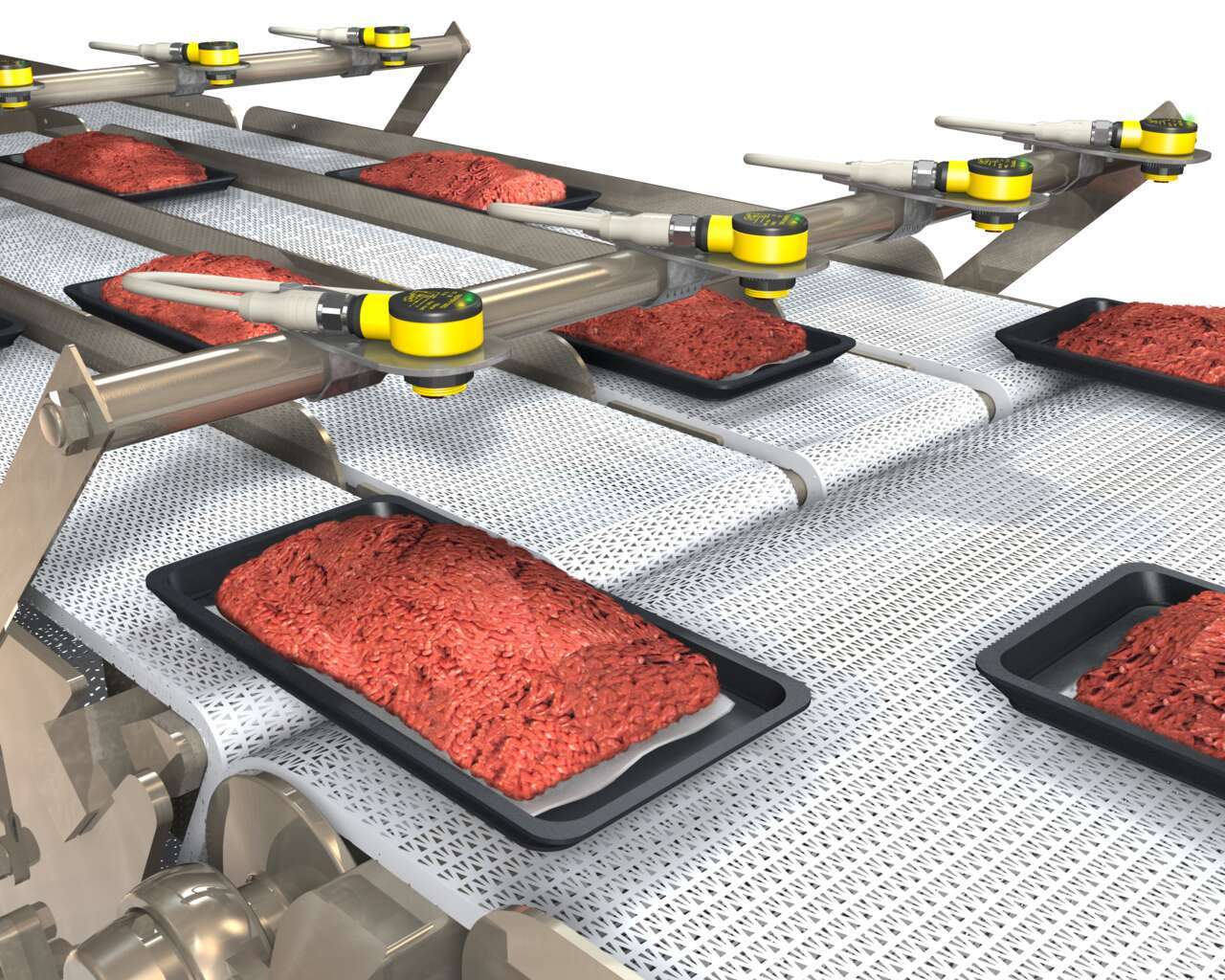

Learn how the Q4X detects dark colored trays at hopper and filling station in the food industry.

Learn More

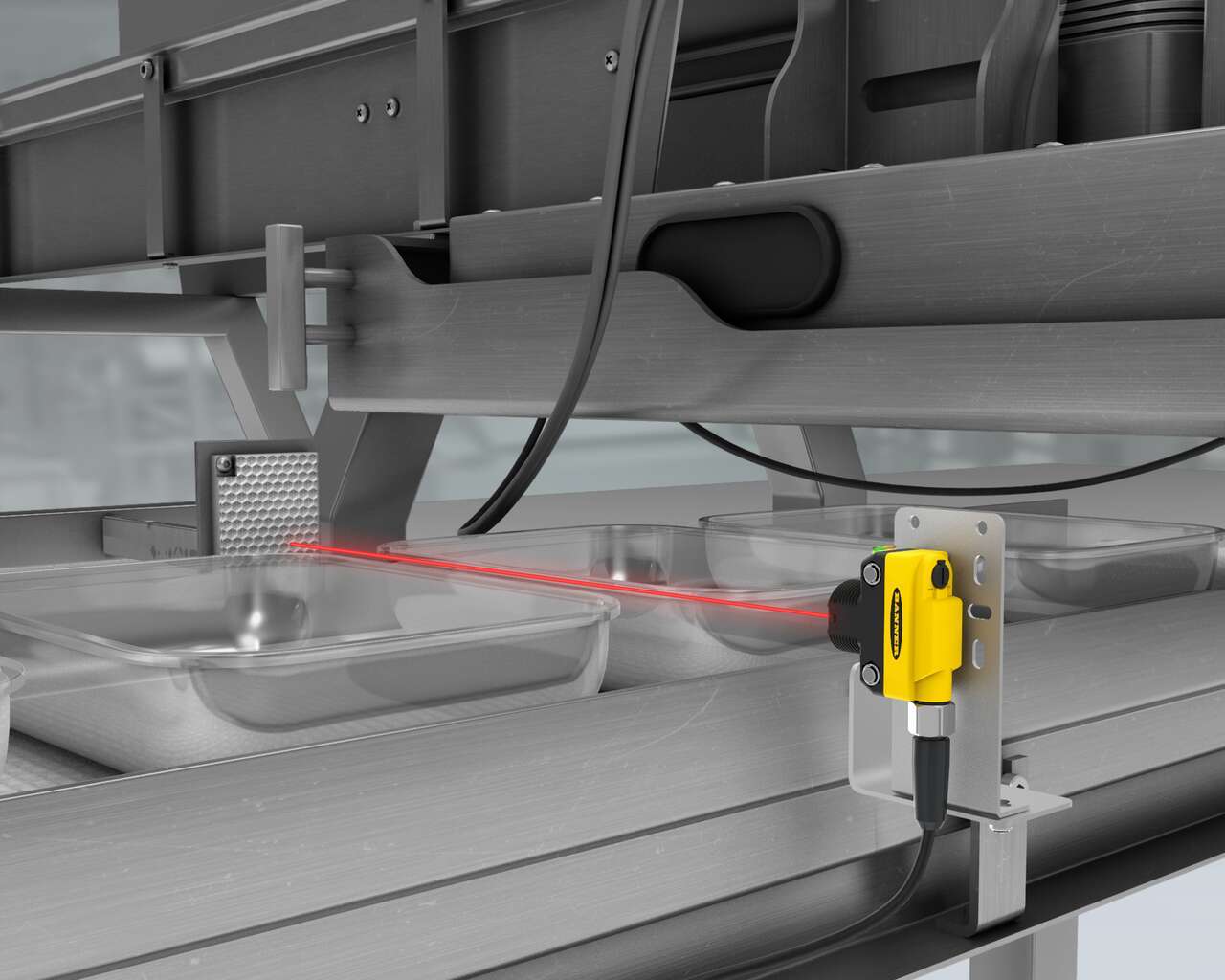

Using a sensor in clear object sensing mode to ensure proper staging of plastic trays during denesting process.

Learn More

The sensing characteristics of this application are simple, yet unique: the sensors are positioned directly above a white, highly reflective background and must detect darker, lower contrast objects of varying texture. The EZ-BEAM T18 fixed field sensor is an ideal solution. It has a sharp detection cutoff and is not sensitive to color variations – it will signal the presence of an object within a certain range and ignore the background.

Learn More

Alert operators of the fail status on a checkweigh station on a food processing line in a harsh washdown environment.

Learn More

The two-point teach option on the Q4X analog laser measurement sensor is used to teach the full and empty magazine. Manual adjustment can be used to fine tune the output. The analog output provides a real time gauge of the stack height. This allows the cartoner machine to have several “call for parts” set points without having to manually move the sensor. The Q4X is a robust, rugged stainless steel sensor ideal for use in many industrial, factory environments.

Learn More

The QS18LD laser diffuse sensor scans across the top of the package to see if any flaps are open. The laser diffuse sensor provides accurate detection to verify whether the frozen packages are sealed properly.

Learn More

Banner’s S18-2 barrel sensor is a cost-effective, reliable sensing method for this type of application. Its small size makes it easy to integrate along the manufacturing line, and its competitive price means it is well-suited for applications requiring multiple sensors. With a powerful and bright visible red emitter beam, the S18 sensors are easy to align during set up.

Learn More

Operators access machine systems through the control cabinet and need Intense illumination of the cabinet facilitates for maintenance and management.

Learn More

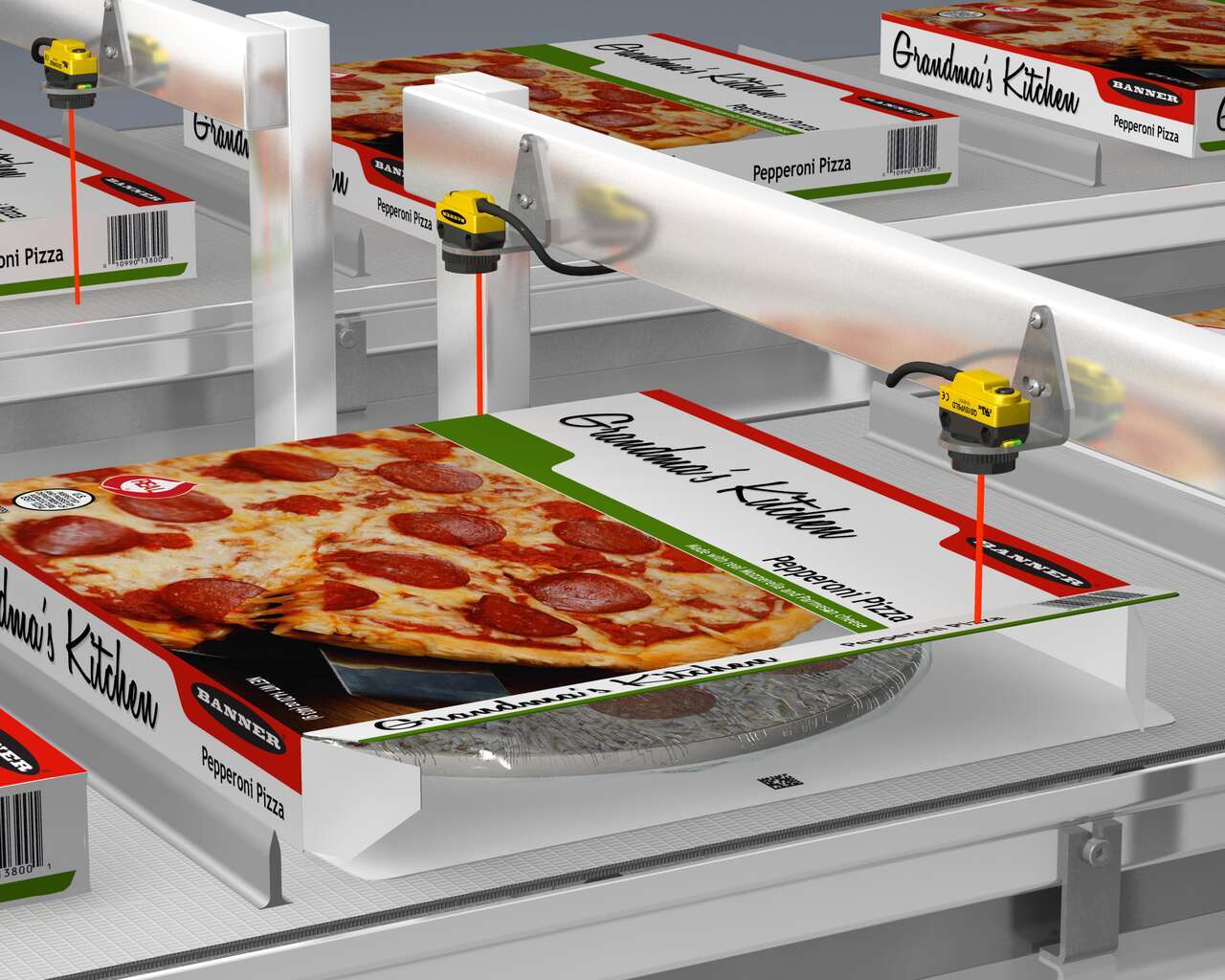

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

Learn More

Safety light screens on a meat slicer protect operators from sharp blades while in operation. The environment is harsh and frequently exposed to chemical washdowns. The EZ-SCREEN LS with hygienic enclosure keeps personnel safe while preventing water and chemical damage to the light screen.

Learn More

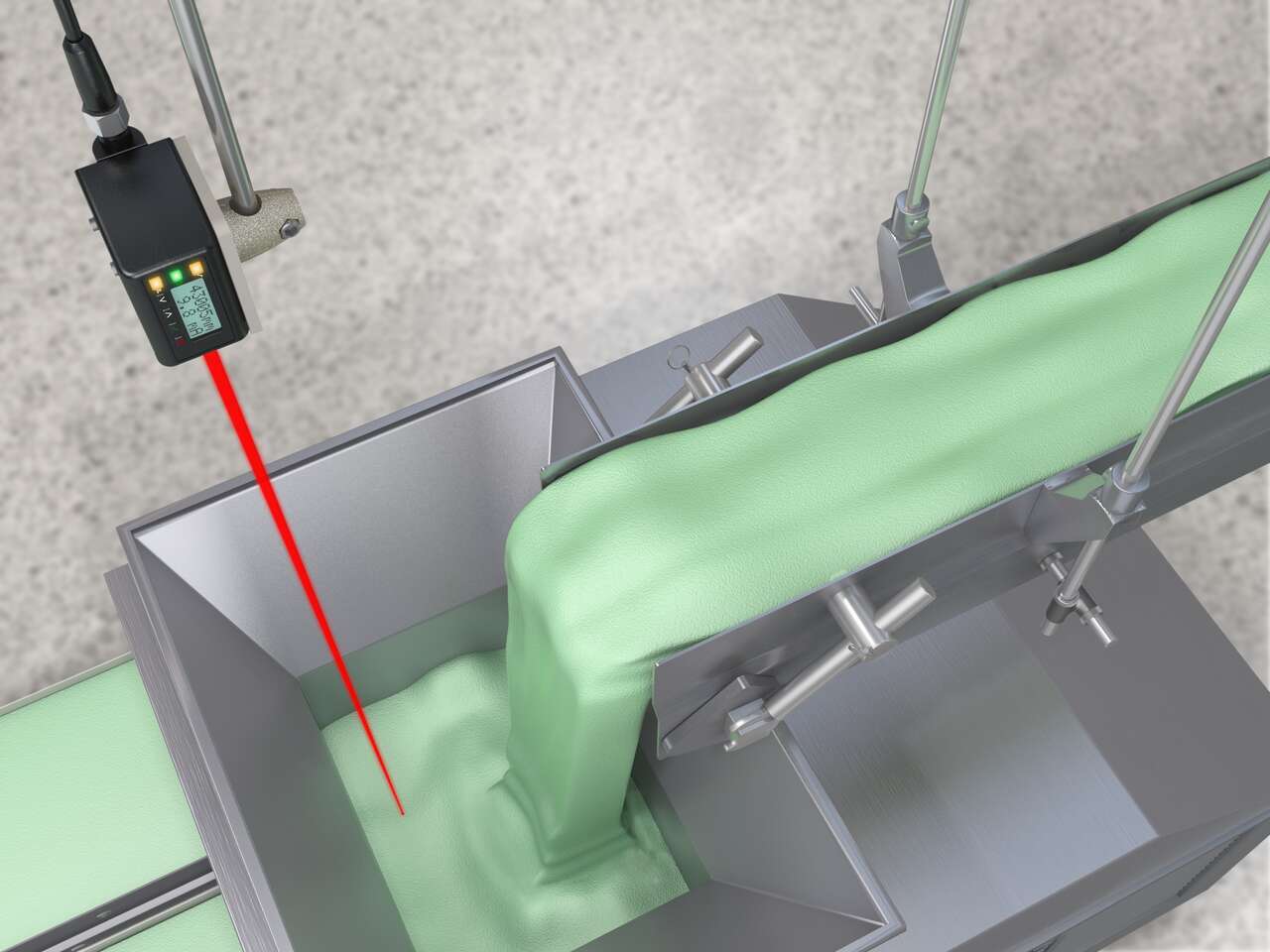

Banner’s LE550 is factory configured with a range of 100 to 1000 mm and can start measuring immediately. If the range needs to be adjusted, the laser sensor has an intuitive user interface with a two-line, eight-character display, making it easy to automatically or manually adjust settings. The LE550 provides repeatability and accuracy across challenging targets, from metal to black rubber, allows for reliable measurement of the shrink wrap.

Learn More

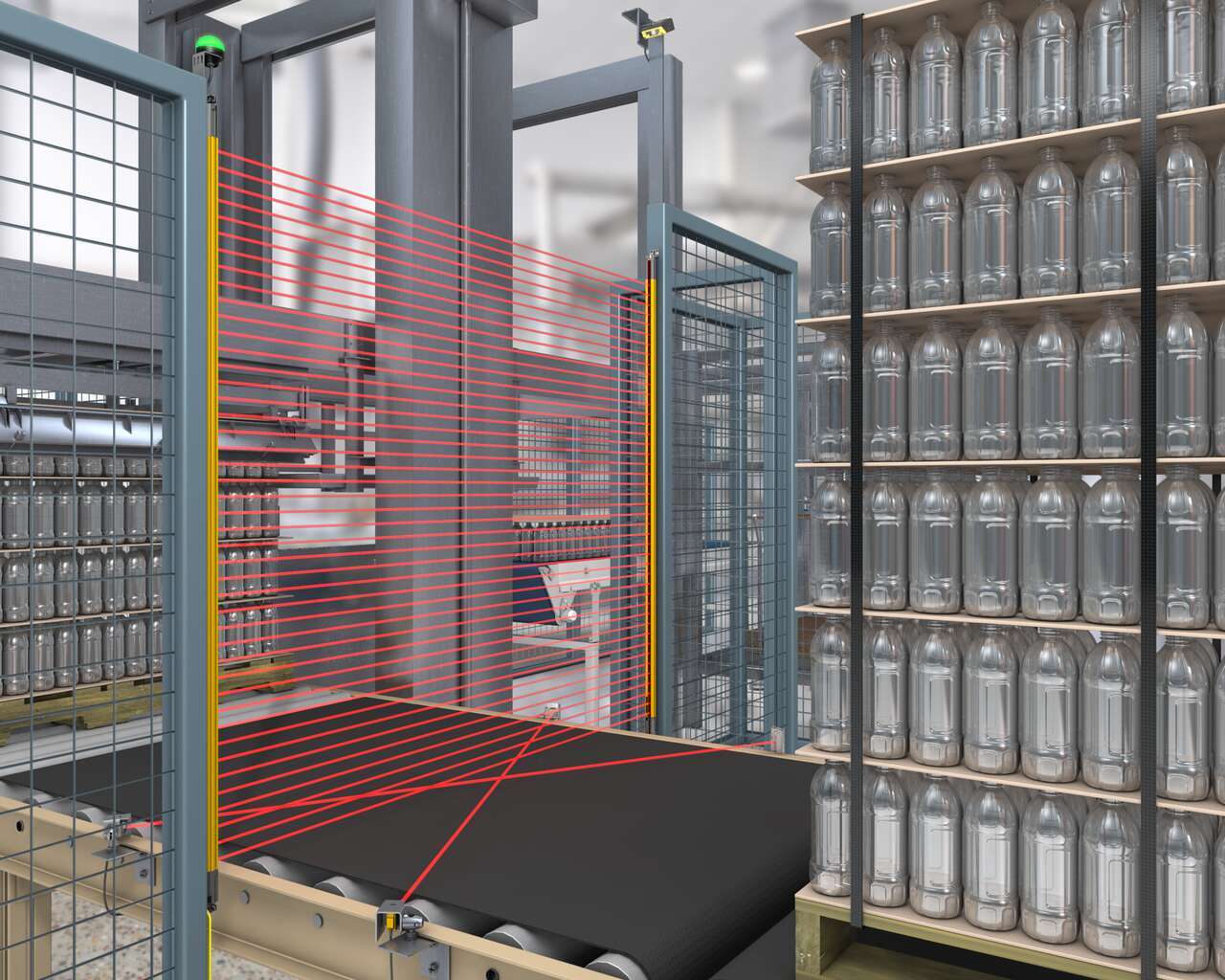

A company needed a way to safe-guard the area where pallets of empty bottles or cans enter into the depalletizer. Learn how Banner Engineering's XS26-2 Safety Controller with EZ-Screen safety light and LS-S safety light curtains helped maintain a continuous flow of pallets while protecting hazardous areas of a machine from workers.

Learn More

Banner offers IP68 and 69 rated products and solutions designed specifically to perform reliably in harsh conditions and withstand the environmental challenges common to primary packaging areas in the food processing industry.

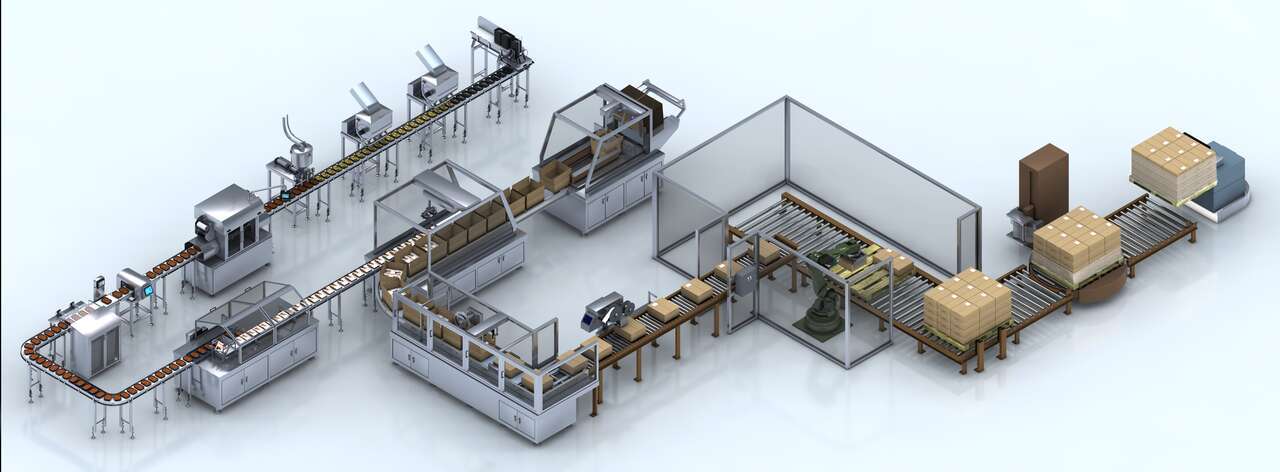

Banner’s rich industry knowledge and expertise in sensors, LED lighting and indicators allow us to offer products and solutions that help food processors maintain a continuous flow of products throughout secondary packaging and ensure their packages are secure and products are protected.

From sensors that regulate the flow of packed cases into the assembly and palletizing areas to safety controllers that simplify and centralize the management of safety devices, Banner products solve problems for food producers at the end of the line.

View industrial automation solutions for each machine through primary, secondary, and end-of-line food packaging.

Laser Distance Measurement | Q4X

This smart sensor solves countless problems, has the power and capability of several sensors in one, uses a food-grade housing, and does not require a reflector target.

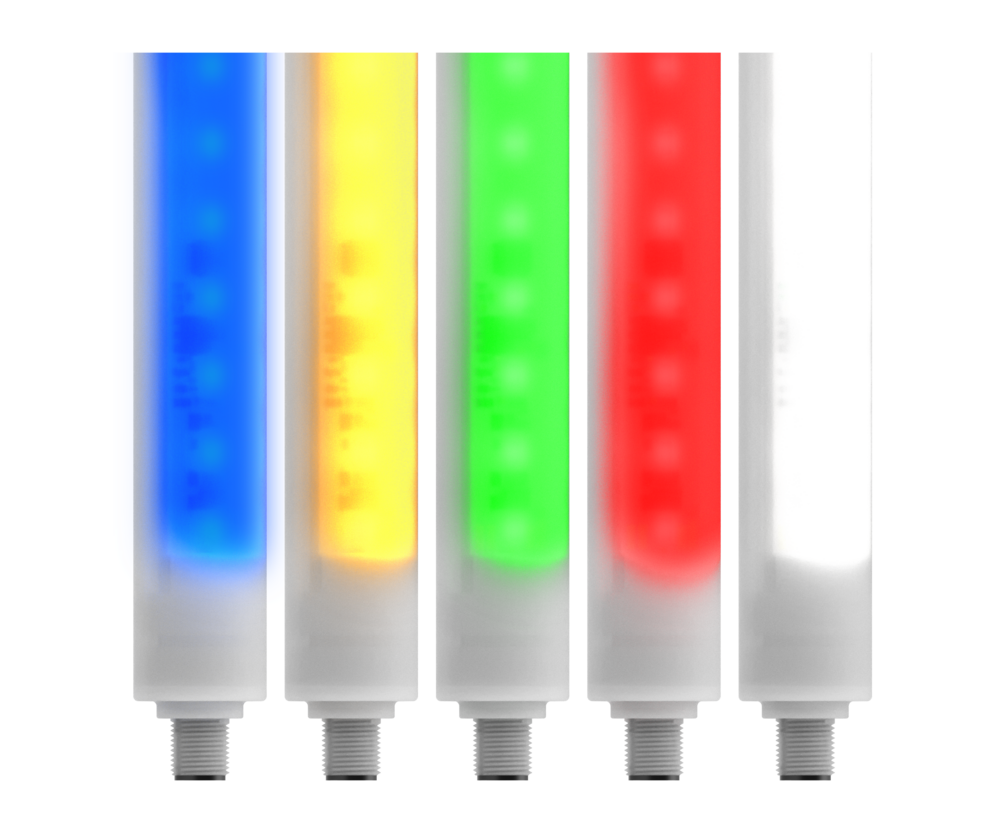

Illumination and Indication | WLS27 EZ-STATUS

Fully encased in a shatterproof, chemically resistant housing. Rated IP69K for washdown. Multiple color options combine illumination and indication.

Upgrade from traditional relays to get better diagnostics | SC10

Replaces the functionality of two safety relay modules with one compact, cost-effective device. Supports up to 10 inputs, 4 convertible inputs, and 2 dual channel 6 Amp relay outputs.