Triggering Checkweigh Station as Plastic Food Trays Travel on Conveyor

Application: Detecting Food Tray Presence with a Trigger Sensor

Challenges: Frequent Washdown Environment

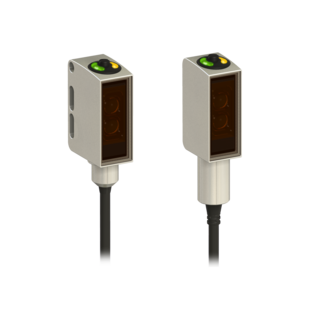

Solution: Banner Engineering’s QM26 Washdown Sensor

Benefits: Chemically resistant IP69K rated stainless steel housing

In order to provide a consistent and high-quality product, food companies need to make sure that their material meets weight requirements. However, sensors that are used within the food industry are often introduced to high pressure washdown conditions that can potentially alter or damage the sensing equipment. A sensing solution is needed that can withstand washdown environments while reliably detecting plastic material and triggering the checkweigher.

Quality Sensing in High-Pressure Washdown Areas

As a tray of food moves along the production line, it will proceed onto a checkweigher. A rugged sensor is needed that can reliably detect the plastic food tray and withstand a harsh and wet environment. Once the sensor confirms the presence of a filled food tray, it triggers the machine to weigh the product.

The QM26 washdown sensor is rated to IP69K and has FDA compliant, stainless steel housing which makes it ideal for high-pressure washdown environments. These sensors were created to have a hygienic design with minimal grooves for easy cleaning. They are also ECOLAB certified for prolonged sensor life in chemically-cleaned environments. Adding a QM26 sensor to a food production line is easy thanks to a bright red light for sensor alignment and simple mounting.