Perimeter and Access Guarding

Protect Access to Hazardous Work Areas

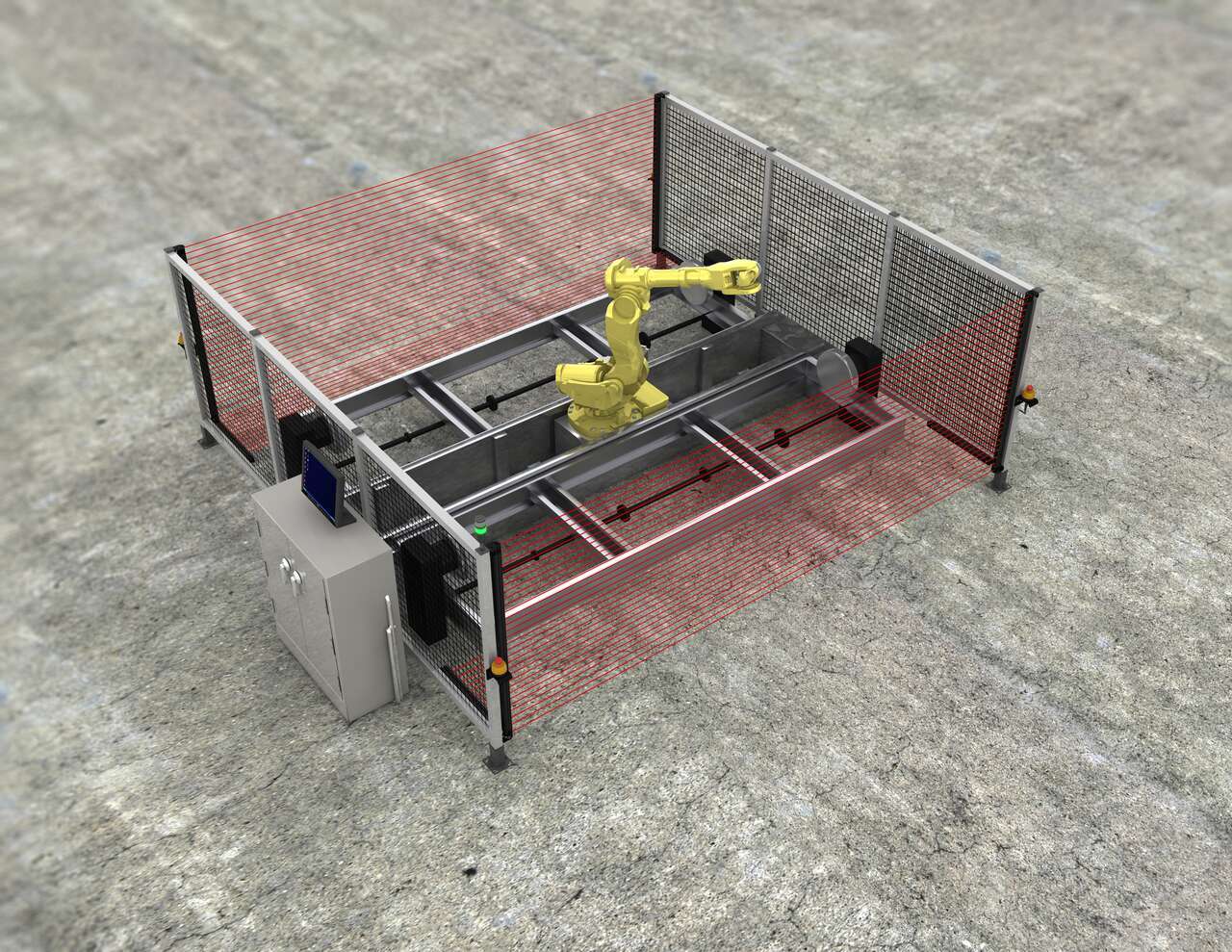

Perimeter guarding applications require guarding on multiple sides of the machine. Meanwhile, access guarding protects a specific access point into the hazardous area. For perimeter and access guarding, protective measures are mounted farther from the pinch point compared to point of operation applications.

Hard guards—such as fences—are a common solution, but they take up floor space and are difficult to move. Meanwhile, optical devices like safety light curtains, and grids save space and can be moved to meet changing requirements. Many applications use a combination of hard guards and optical safety devices for perimeter and access guarding.

Safety light curtains, grids, and points are all optical safety devices that typically consist of an emitter and a receiver, where the emitter sends beams of light to the receiver. The safety device detects when an individual or object interrupts any of the beams and will trigger a halt to the hazardous motion.

Safety light curtains have the most sensing beams--which create a screen of protection that can be used to detect a hand or finger, depending on the resolution. Safety grids typically have 2, 3, or 4 beams total for detecting an arm or torso, and safety point devices have just one beam of light.

Please note: The information on this page is meant for educational purposes only and is accurate as of the time of publication. Always consult a safety expert about your specific application prior to implementing any machine safety measures.

Long Range Devices Protect Large Access Points

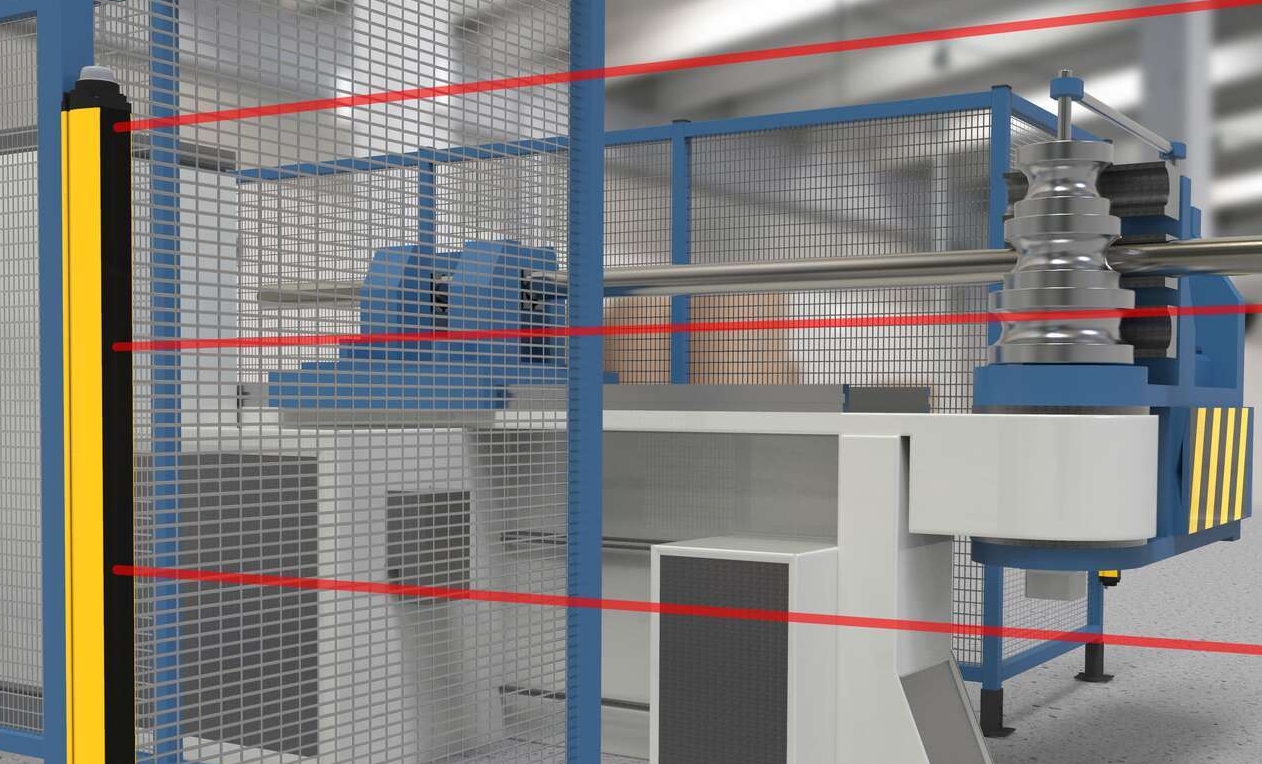

Machines and hazardous work areas can be expansive, stretching tens of meters across the factory floor. Guarding the entire perimeter of the machine with fencing is often impractical, takes up valuable floor space, and reduces sightlines.

In applications like safeguarding access to a tube-bending machine (pictured left), a long range sensing solution can ensure the safety of workers while providing greater flexibility and visibility. Safety grids and single-beam safety devices have exceptionally long ranges of up to 60 meters (196.85 feet) and are ideal for long distance applications.

Mirrors Help Guard Perimeters with Fewer Devices

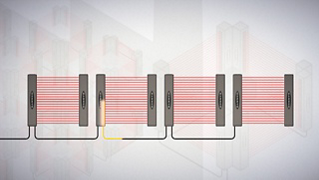

Perimeter guarding often requires guarding around corners to ensure that access to the hazardous area is protected on all sides. There are several ways to do this. One option is to cascade multiple light curtains or grids together, utilizing a separate emitter/receiver pair for each side of the perimeter.

Alternatively, corner mirrors are an economical way to make use of the long range of a safety light curtain or safety grid. Using mirrors allows you to guard multiple sides of an area with one emitter/receiver pair, saving costs and reducing the number of devices that need to be maintained.

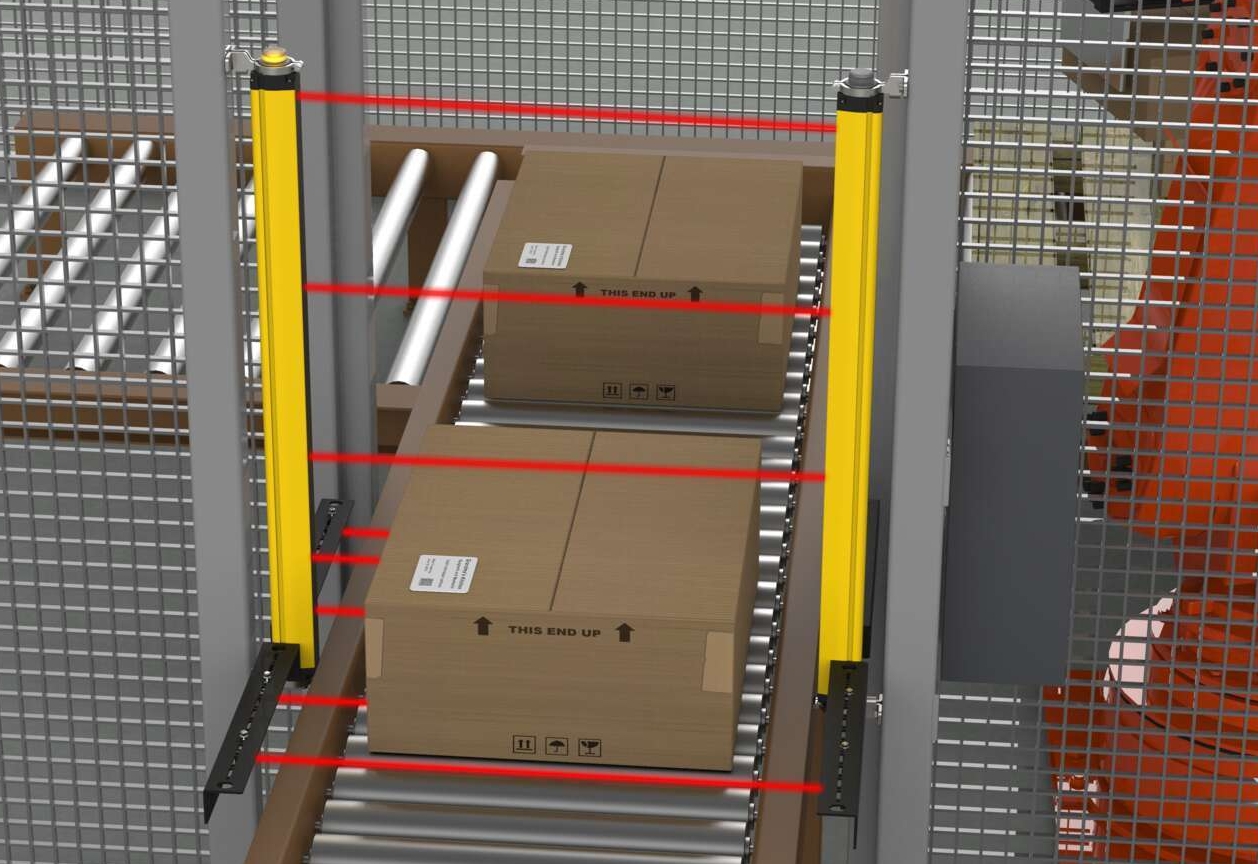

Muting Enables Safe Material Entry and Exit

In many applications, such as depalletizer machines, personnel need to be protected from entering hazardous areas, but materials must still be allowed to flow freely through the protected entry and exit points. Safety light curtains and grids use muting to allow materials to flow through without tripping the safety system and stopping the machine, while still protecting operators from injury.

When muting is enabled, muting sensors detect the moving part within a prescribed sequence and time. If the sequence is correct, the light curtain will be muted temporarily while the part moves through the guarded access area. The light curtain or grid becomes active again once the part has cleared the guarded zone. This allows materials to flow efficiently in and out of the area while personnel are protected from the hazards.

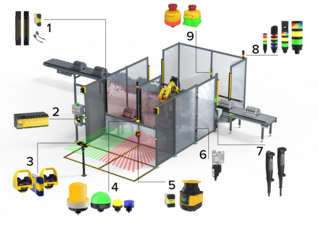

Easy-to-Use, Full-Featured Safety Light Curtain

LS light curtains are intuitive, easy-to-use safety devices used for machine safeguarding. They are built to withstand challenges commonly found in manufacturing and packaging environments.

- Full-featured models with options to meet a wide range of applications

- Heavy-duty aluminum housing and recessed window to avoid damage in harsh environments

- End-to-end sensing

- Highly visible alignment and diagnostic indicators

- 14, 23 & 40 mm resolution (detection capability)

- Available in 23 defined area heights from 280 to 1820 mm in 70 mm increments

- IP65/IP67 environmental rating with IP69K models available

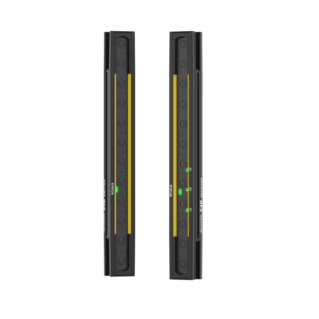

Safety Grid for Perimeter and Access Guarding

SGS Safety Grid Systems are cost-effective multiple beam safety light devices for access and long-range perimeter guarding applications.

- Models available with integral muting for entry/exit conveyors or palletizing cells

- Heavy-duty aluminum housing for tough environments

- Easy alignment and installation with on-board alignment lamp and indicators

- Protective defined area heights of 500, 800, 900, or 1200 mm available

- Up to 60 meter range available for perimeter guarding applications

- Muting arm kits available to simplify end-of-line packaging applications