Guarding Conveyor Entry on Palletizer Machines

Application: Safeguarding palletizer machine at conveyor entry points

Challenges: Packages enter the palletizer area while the hazardous machine remains in operation

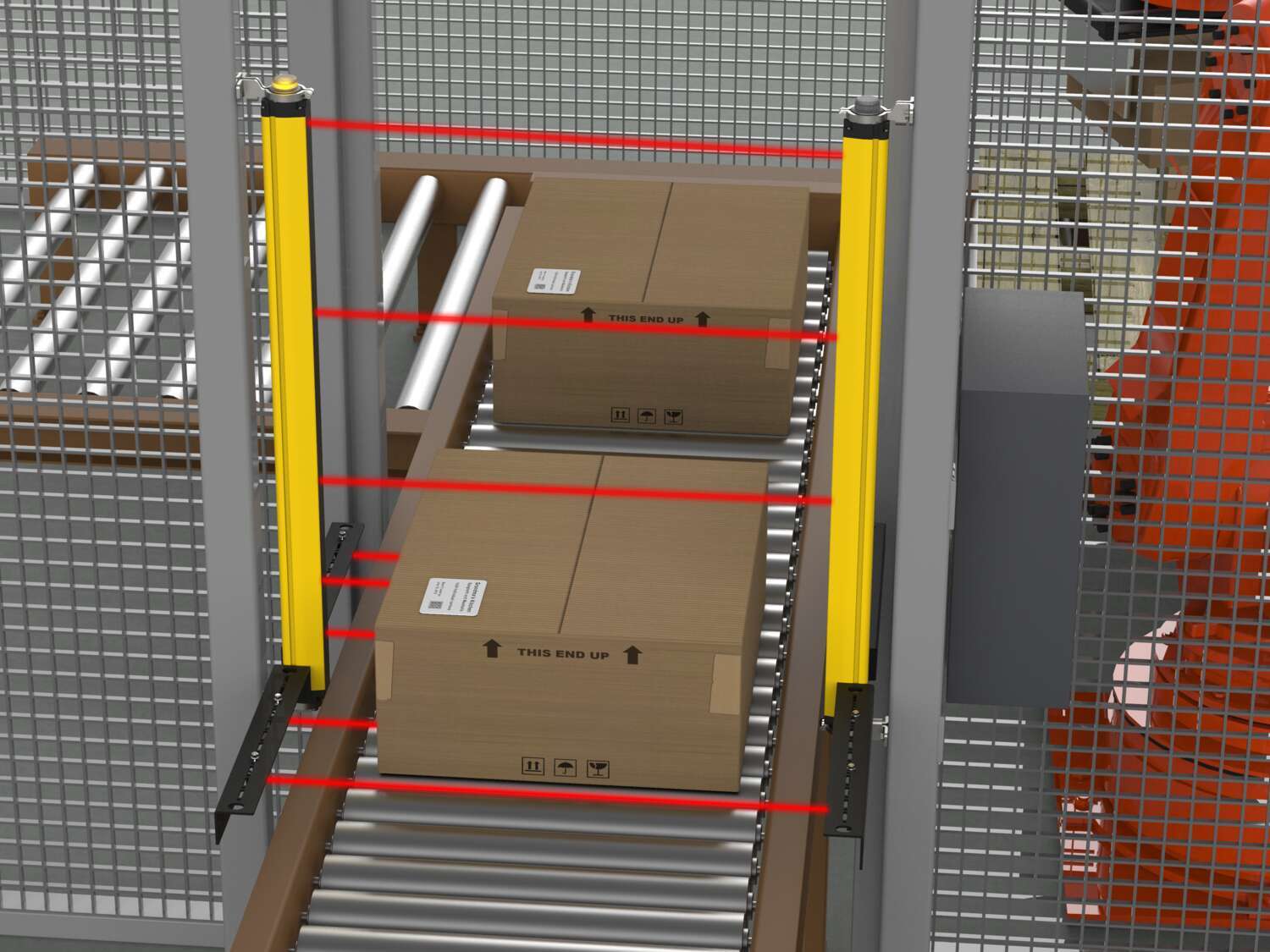

Solution: SGS Safety Grid System with muting control, T-configured muting arm kit

Benefits: Simple safety solution with muting and cost-effective setup

Robotic palletizers often cover large areas with numerous heavy-duty moving parts that could harm employees. Robotic arms are excellent ways to keep end-of-line packaging efficient, but it needs to remain a safe working environment. To keep employees safe, all entry points need to be guarded while the palletizer machine is in operation. Safeguarding becomes even more complicated when items are entering the area via conveyors while the machinery remains in motion. A reliable safety solution is needed that can protect personnel from danger while still maintaining an efficient workflow.

Grids with Built-In Muting Control Simplify Safety

Consistent workflow and high throughput are incredibly important for end-of-line packaging. Any delays at this stage could cause profits to decline. Fortunately, safeguarding tools with correctly integrated muting technology can comply with today’s safety standards while allowing predetermined objects to break the beams. This cuts back on downtime by not shutting down the conveyor or palletizer machine as it transfers product into hazardous areas.

Banner Engineering’s SGS Safety Grid System is a simple way to safeguard palletizer areas. The heavy-duty aluminum housing withstands tough working conditions and features two, three, or four beams that detect a body or torso passing into the hazardous area. The grids are available in Emitter/Receiver models as well as Active/Passive models. Active/Passive models consist of a mirror assembly and an active transceiver that houses both the emitter and receiver. Only one side of the deployment requires power and wiring, simplifying installation and reducing costs.

Installing SGS Safety Grids on the conveyor access point safeguards the palletizer and surrounding area. Certain SGS models are available with integral muting for these specific types of entry/exit applications. Integral muting means that the muting technology is built into the device and eliminates the hassle and additional expense of using an external muting controller. Grids with built-in mute controllers make installation simple and more cost-effective than more elaborate safety systems.

To simplify the safety solution even further, Banner now offers muting arm kits. They are pre-assembled and ready to mount and use right out of the box. For this conveyor entry application, a T-configuration is used, but muting arm kits are also available in L- and X-configurations. The kits use pre-mounted hardware and specialized Q20 retroreflective sensors and reflectors. These easy-to-align kits reduce initial installation costs by eliminating additional sensors and excessive wiring.

As the packages enter the dangerous workspace, the beams on the mute arm kit are broken in a pre-determined pattern and the SGS Grids switch into mute mode. This allows the packages to pass through the light curtain while the machine remains in operation.

If the muting deployment pattern is inconsistent or the grid beams are broken prior to the muting function taking place, the safety outputs trigger a machine stop condition to avoid harming those in the area. An attached mute indicator light will turn on while the Grids are in mute mode so that nearby personnel are alerted of the mute status.