-

Company

-

Banner Blog

-

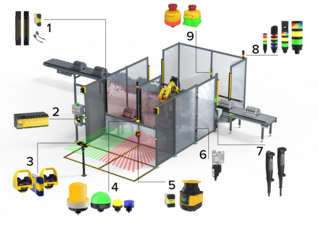

Infographic: 9 Common Machine Safety Devices

Infographic: 9 Common Machine Safety Devices

Mechanical hazards on machinery typically occur at points of operation, points of power transmission, and other points of machine movement. Safeguarding devices are designed to limit the risk to personnel for accident or injury at these points. In the illustration below, common machine safeguarding devices are used to mitigate multiple points of risk on a robotic work station.

Please note: The information provided here is for educational purposes only and is accurate as of the time of publication. Banner recommends consulting a safety professional about your specific application before implementing safety measures.

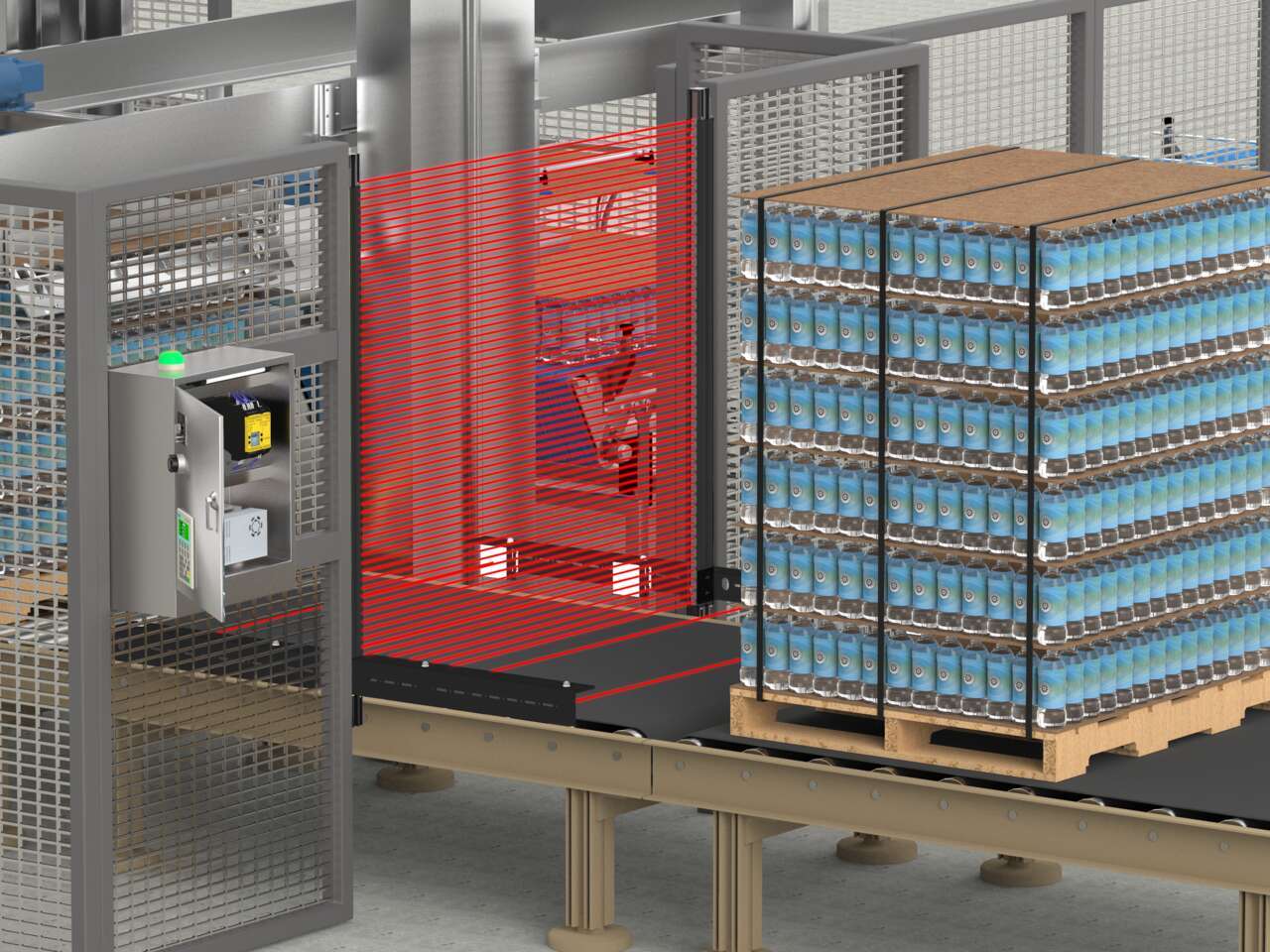

1. Safety Light Curtains

Safety light curtains protect personnel from injury and machines from damage by creating a sensing screen that guards machine access points and perimeters. An individual or object interrupting any beam in the screen will trigger a halt to the hazardous motion.

2. Safety Controller

A safety controller monitors multiple safety and non-safety input devices, providing safe stop and start functions for machines with hazardous motion. A single safety controller can replace multiple safety relay modules in applications that include E-Stop buttons, safety light curtains, interlocking gate switches, and other safety input devices.

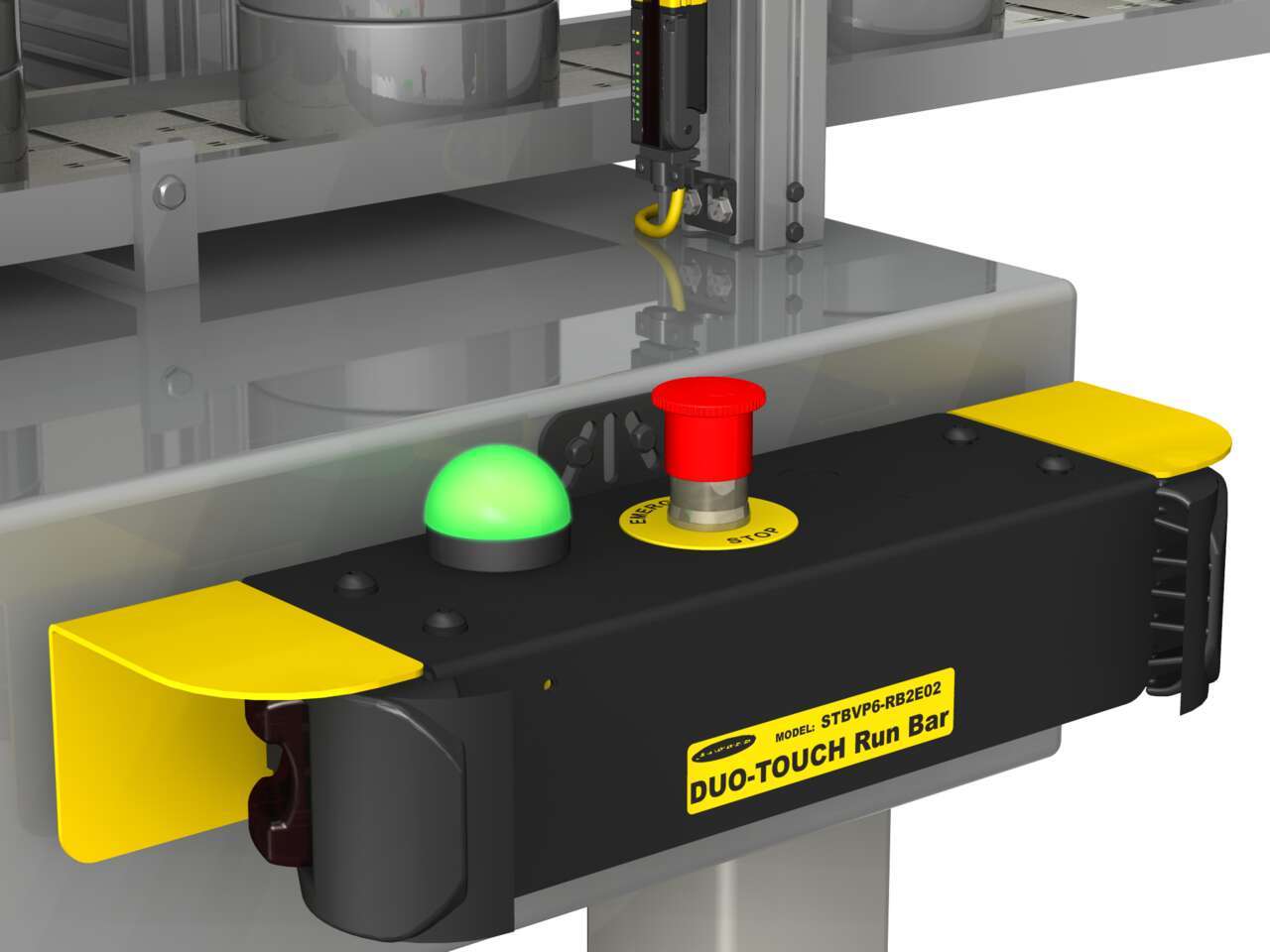

3. Two-Hand Control Devices

By requiring that a machine operator use both hands to initiate and continue a machine cycle, two-hand control devices keep the operator at a safe distance from the hazardous motion of the machine. If one or both hands are removed from the device, the machine de-energizes, bringing the hazardous motion to a stop.

4. Indicator Lights

Available in single and multicolor options, LED indicator lights provide high-visibility real-time indication of equipment and safety status. They have a compact, low profile design that enables deployment in areas where other indication solutions would interfere with machine motion.

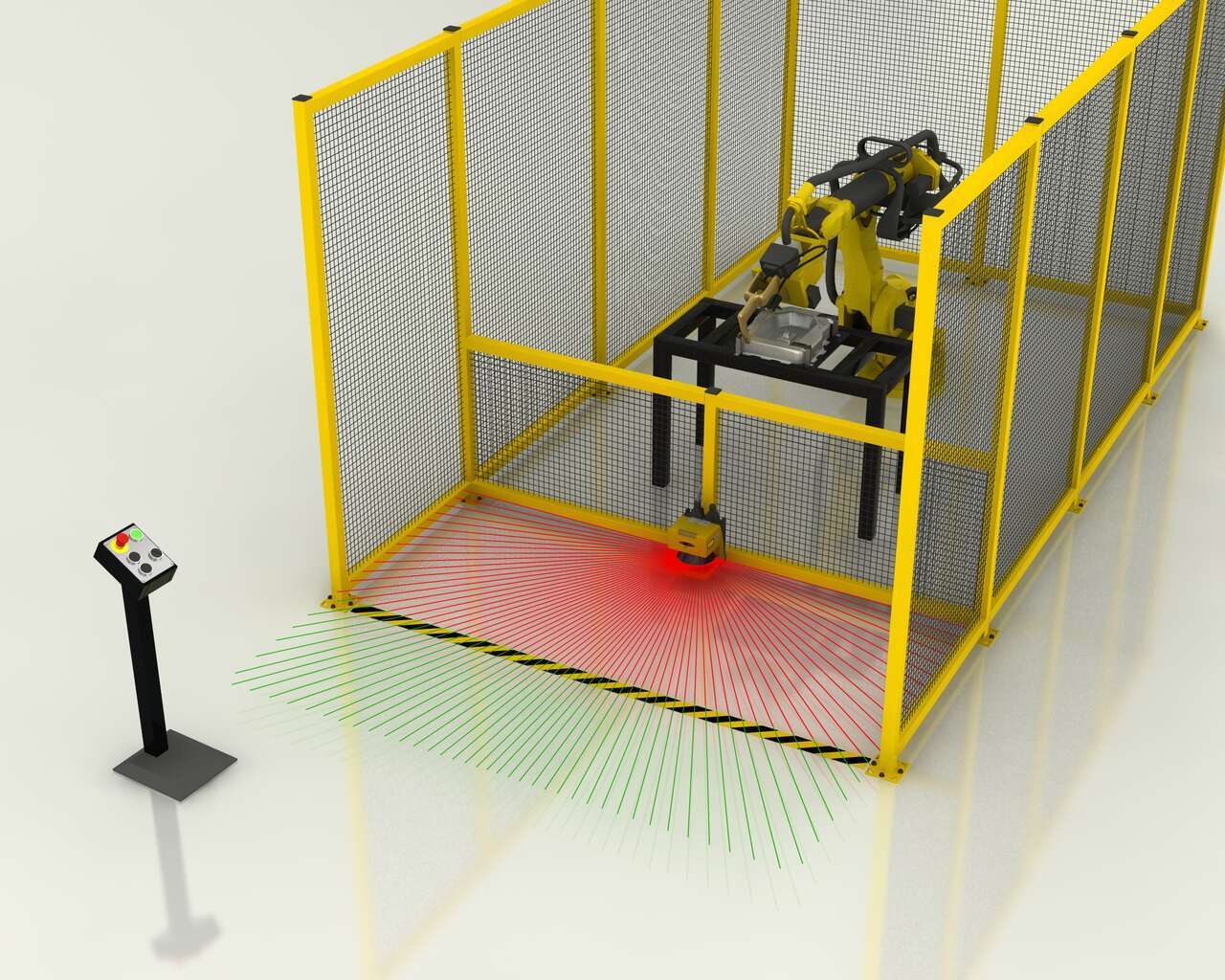

5. Safety Scanner

Safety laser scanners protect personnel and equipment within a user designated area. These flexible safety solutions are ideal for safeguarding complex and irregularly shaped areas and mobile assets that cannot be easily solved using other safeguarding solutions.

6. Safety Interlock Switches

Safety interlock switches monitor the mechanical guards that separate an individual from a hazard. If a guard, like a gate, door, or panel is opened or removed, the safety interlock switches send a signal to the machine control system to halt the hazardous situation.

7. Enabling Devices

Enabling devices initiate a safety function when a user either squeezes or releases the handle grip switch. When continuously activated and used in conjunction with a separate actuating control, these devices allow a machine to function in manual operating mode.

8. Tower Light

Visible from all angles, over long distances, and in bright conditions, modular tower lights provide real-time machine or safety status indication. These customizable, high-visibility indicators have options for AC and DC supply power, single and multicolor segments as well as audible modules.

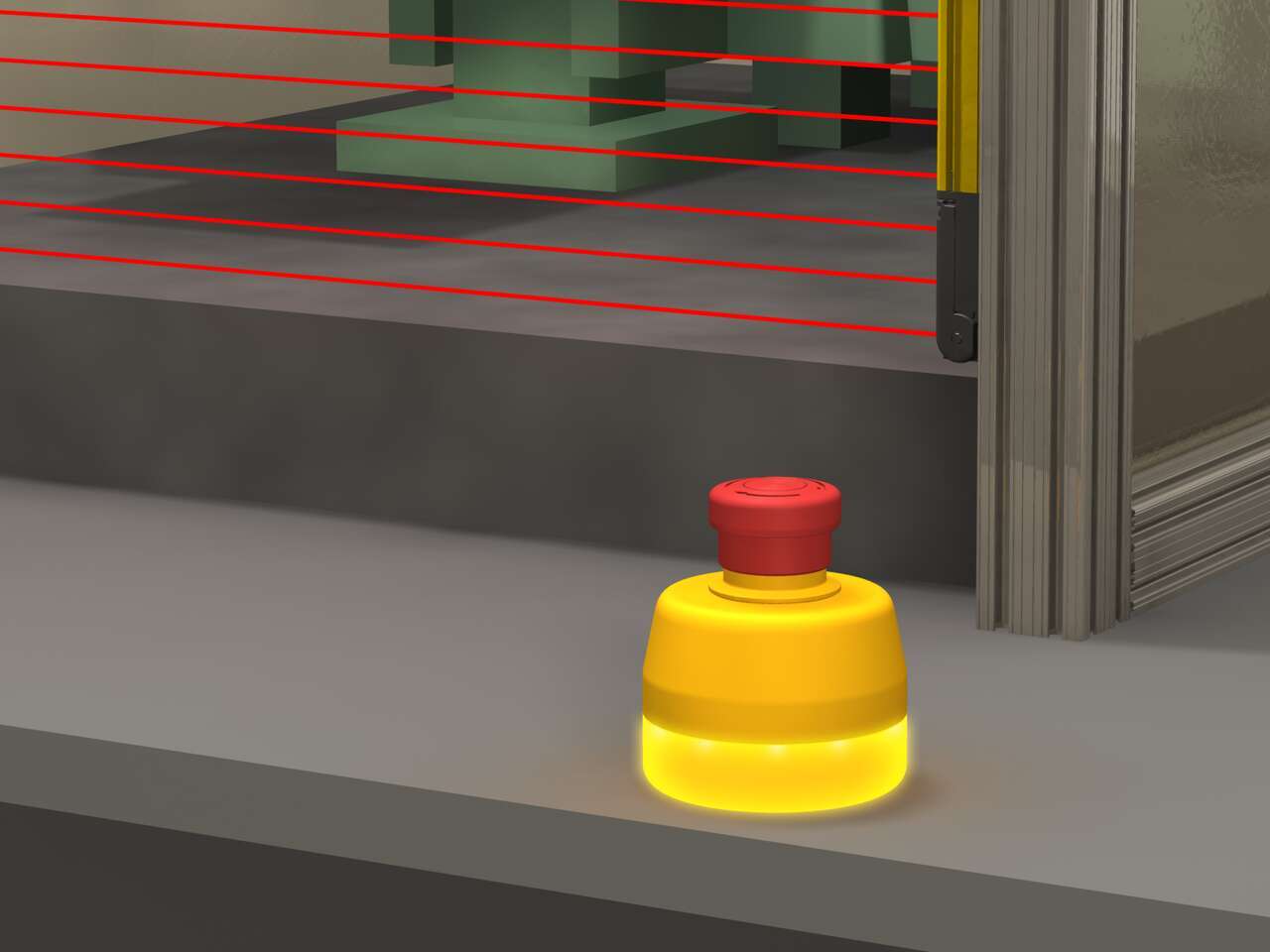

9. Emergency Stop and Stop Control

Emergency stop devices allow workers to quickly stop a device by pushing a button or pulling a rope in order to prevent injury to personnel and material loss. These devices are wired to override all other machine controls and remove power from hazardous machine motion.

Easy-to-Implement Diagnostic Capabilities for Safety Systems

In-Series Diagnostics (ISD) makes it easy to access diagnostic data from devices in a safety system without special equipment or designated cabling. Users can troubleshoot machine safety systems, prevent system faults, and reduce equipment downtime.

This innovative, next generation technology is exclusive to safety devices from Banner Engineering, including SC10 Series safety controllers, SI-RF Series RFID safety switches, and E-Stop buttons. ISD compatible devices achieve the highest levels of safety (Category 4, PL e, or SIL CL 3 safety ratings).

This article is for educational purposes only and is accurate as of the time of publication. Banner recommends consulting a safety professional about your specific application before implementing safety measures.