-

Products

-

Machine Safety

-

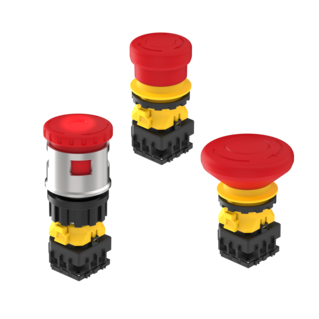

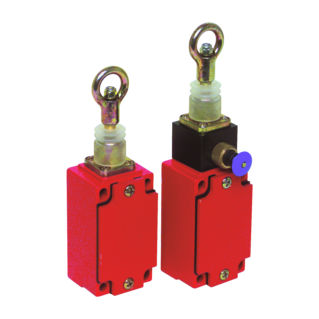

Emergency Stop and Stop Controls

Emergency Stop (E‑stop) and Stop Controls

Emergency stop devices, or E-stops, provide workers a means of stopping a device during an emergency by pushing a button or pulling a rope in order to prevent injury to personnel and material loss.