Transcript

Whether you use the term “IIoT,” “Digitalization,” “Smart Factory,” or “Industry 4.0,” data process optimization in factories is the next big evolution. And as businesses seek to meet increasing productivity demands, there’s a strong need for greater insight about equipment and operations. But many manufacturers soon discover that IIoT implementation can be more challenging than expected, whether that’s because their manufacturing processes are dependent on legacy equipment, or data from different equipment comes in unique formats or protocols, resulting in automation islands that provide limited insight, but are neither complete nor actionable.

Until now.

Increase productivity and unlock your factory’s true potential with ‘Snap-Signal’-- a hardware and software tool-kit for your IIoT evolution, available only from Banner Engineering.

Snap-Signal is an easily deployable, complete portfolio of modular IIoT hardware and software that delivers actionable machine data from across your factory.

More than just another flavor of IIoT, Snap-Signal is an overlay network that can capture data signals from virtually any source. It seamlessly converts these sources to a single industry-standard protocol, then distributes the data for quick and easy consumption.

Snap-Signal is brand-agnostic, but it’s also flexible enough to be implemented at any point along your data-flow chain, and is an ideal solution for both modernizing legacy equipment and integrating with new machine builds.

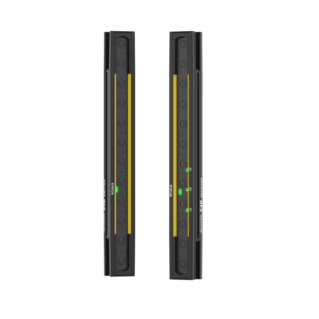

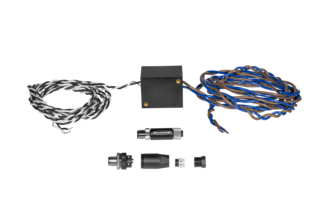

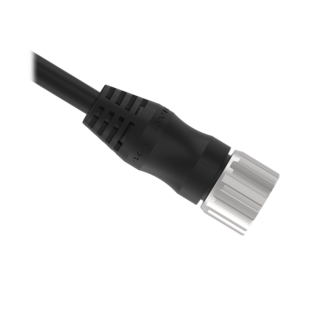

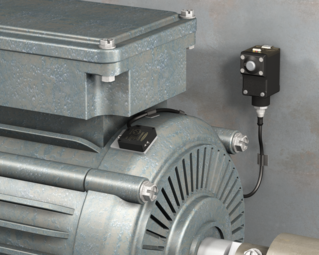

Each device, regardless of original signal type, is first connected to an M12 cable. If a device doesn’t have an M12 connector, field-wirable solutions are available for just about any wiring layout.

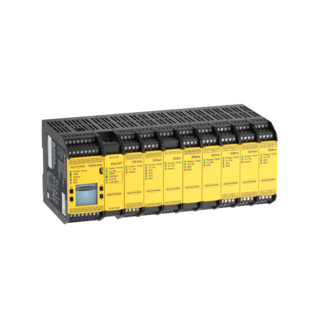

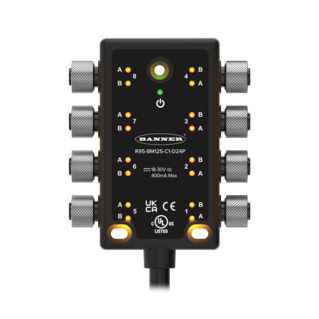

The individual signals are then unified and transmitted with a variety of Snap-Signal cordsets, converters, and network devices, before being sent to your local HMI, SCADA, or cloud platform where they can be analyzed in real time.

An edge-device can wirelessly push data to your own third-party cloud provider with minimal effort, or if you don’t already have a cloud platform, use Banner’s Cloud Data Services to quickly display and host your data right out of the box.

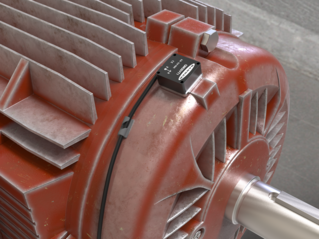

Regardless of whether you are retrofitting existing machines or building new infrastructure, designing and implementing with Snap-Signal is easy and cost effective. Let’s demonstrate by retrofitting this case packer, which currently has no data-monitoring capabilities.

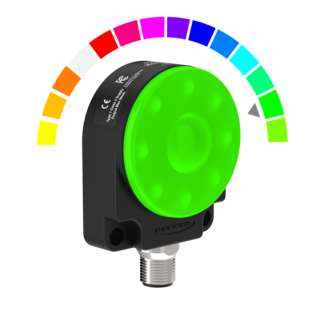

Start by identifying the desired data sources you want to monitor. Remember that Snap-Signal does not need to replace any existing hardware. Decide if any new devices should be added to supplement machine hardware, such as an additional sensor or indicator light.

Then use our system diagram to identify and select the Snap-Signal components you need to bring it all together:

First, add quick-connect splitter cables for every existing source you want to monitor, along with any in-line signal converters necessary.

Next, plan out an optimal wiring path using T-connectors to get the device signals to a Banner smart controller for processing.

And finally, decide whether to output the data through a wired Ethernet protocol for local use, or use an edge gateway device to wirelessly push data to a cloud platform of your choice.

Once the system design is laid out, installation is a breeze:

Start by installing any new devices that you want to use.

Add splitter cables between all of the relevant data sources and their destinations at the machine controls.

Convert all of the signals to a single communication protocol, then connect to a smart controller to complete your network. Finally, send that data over wired Ethernet or wirelessly through an edge device, and begin gathering real-time insight to monitor and improve your machine performance.

It’s that simple to unlock your factory's true potential with Snap-Signal, from Banner Engineering.

To learn more, visit SnapSignal.bannerEngineering.com

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)