Retrofitting for Pallet Detection

The Q76E sensor uses a wide retroreflective beam, which is ideal for detecting palletd items on a conveyor, regardless of their shape, size, or orientation.

Challenge

Conveyor operations that process large, irregularly shaped objects, such as damaged pallets or challenging targets with reflective packaging, require sensors that can detect diverse targets with reliable accuracy. To meet this challenge, manufacturers and other customers retrofitting their automated systems need a cost-effective leading-edge sensor that can instantly detect items of varying shape, size, and position.

Solution

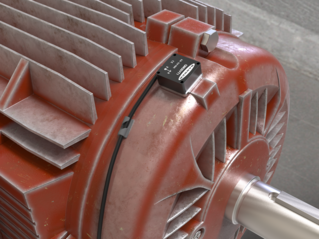

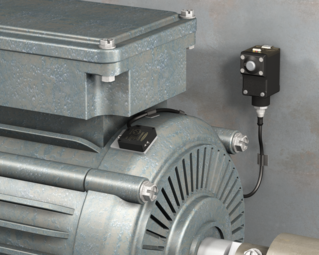

Banner’s Q76E retroreflective sensor uses a wide vertical beam. The beam from a single Q76E crosses the path of a conveyor horizontally to a corresponding reflector, which delivers light back to the sensor’s receiver. This provides superior detection of any object that interrupts the beam, at any angle—making it ideal for retrofitting conveyor systems to reliably identify the presence or absence of palleted items.

Installing the Q76E is simple and easy. Because the sensor uses a reflector, it is only necessary to power one side of a conveyor, and the visible red beam makes alignment quick and intuitive. With a range of up to 4 meters, the Q76E provides maximum mounting flexibility for sensing wide pallets and other large items, yet it also has the precision to detect objects as small as 8 millimeters in size. A single TEACH button can adjust detection sensitivity and toggle between LO (light operate) and DO (dark operate) modes, to adapt the sensor to nearly any target or production environment.

The Q76E essentially creates a two-dimensional vertical detection field. This is perfect for recognizing combinations of objects with inconsistent shapes and sizes—for example, pallets, polybags, boxes, tubes, and totes with gaps or holes—without introducing downtime for sensor recalibration. The Q76E works on shrink-wrapped products, film, and perforated packaging, and it can switch at rates of up to 250 Hz for high-speed production lines. With its robust IP67- and IP69-rated housing, it can even operate in environments with frequent washdowns. Furthermore, an available IO-Link model offers increased data availability for remote configuration and monitoring.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)