Web and Edge Guiding

Ensure Continuous Flow of Materials

Reliable web and edge guiding ensures a continuous flow of product through machine processes, minimizes downtime, and prevents material damage and loss.

Sensors are frequently used to monitor and control webs by measuring the web as it travels on the line.

Banner’s expertise in sensing technology allows us to offer solutions that consistently and accurately measure web material, keeping it centered on the line for continuous flow through the system.

Like many industrial sensing applications, web and edge guiding applications often involve targets that are traditionally challenging for sensors to detect, including clear, reflective, and extremely dark targets.

In addition to material texture, reflectivity, and translucence, the high-speed operation of web guiding equipment can challenge a sensor’s ability to detect and measure the material reliably.

Problem-solving sensors from Banner Engineering provide reliable edge detection for web guiding applications. See a few exmaple applications below, or contact us to discuss your specific application.

Detect Plastic, Glass, and Other Clear Webbing

- Clear objects are some of the most challenging to detect and measure reliably.

- Web material may also be translucent, and a reliable solution is needed to accurately perform sensing tasks such as edge guiding, loop tension control, hole sizing, and profiling.

- Banner Engineering has created a special class of EZ-ARRAY specifically designed to detect clear objects.

- By customizing standard EZ-ARRAY receivers to successfully detect low contrast and operate at a lower sensing range (30 to 1500 mm), Banner has enabled EZ-ARRAY clear object measuring light grids to detect translucent objects such as glass and clear webbing.

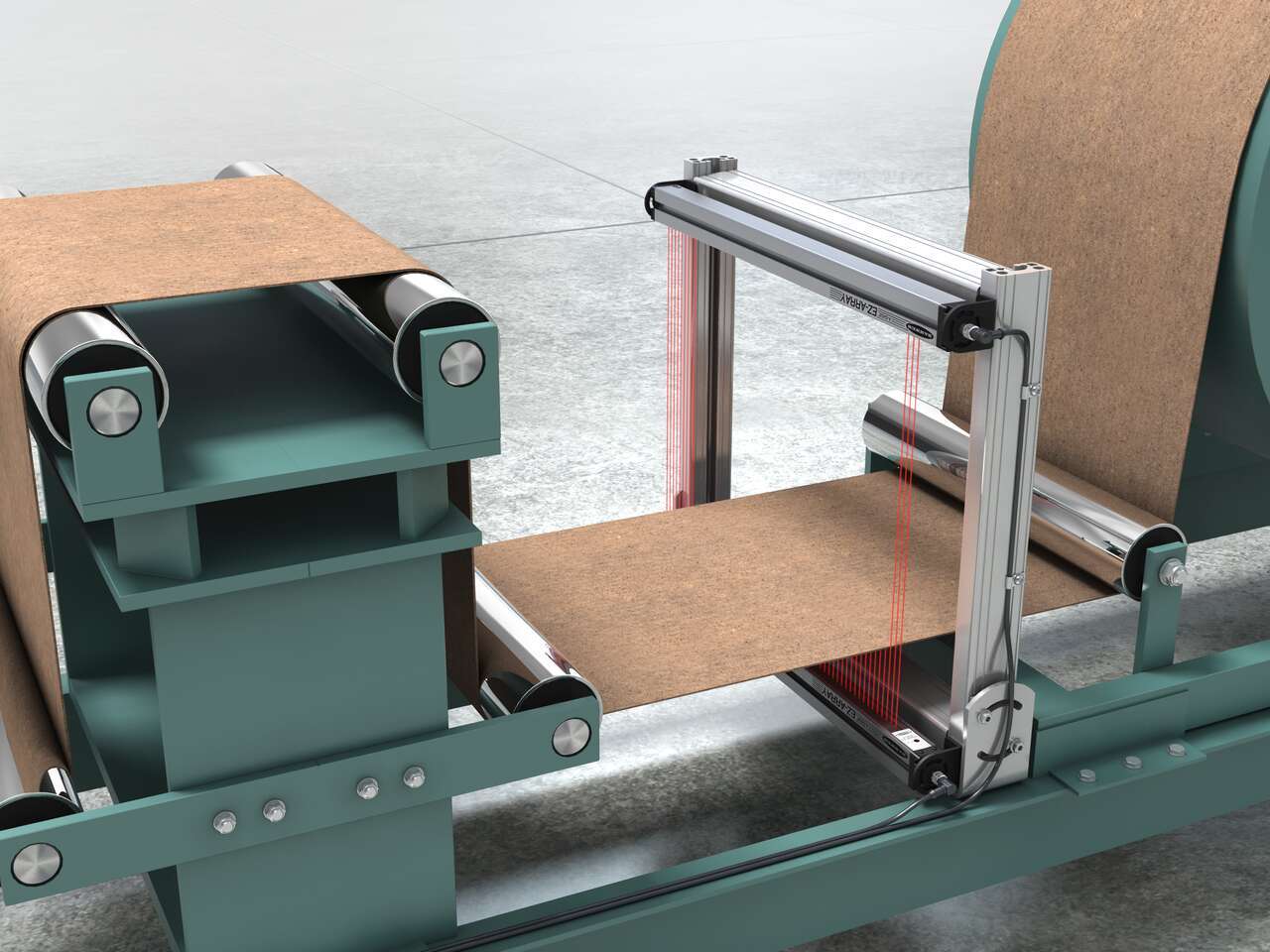

Edge Guiding on a Carpet Web

- Determining the location of the two edge transitions on carpet web is important in carpet manufacturing: the edge from air to selvage and the edge from selvage to tufting.

- Measuring and monitoring these transitions while the web is running is more cost-effective than risking expensive waste in post-manufacturing inspections.

- As the carpet web passes through a pair of EZ-ARRAY measuring light curtains, the two sticks configured for Nap Detection mode monitor the process in action.

- The EZ-ARRAY detects the selvage edge and tufting edge and sends data to the web control system, which can then make necessary adjustments to keep the carpet in line.

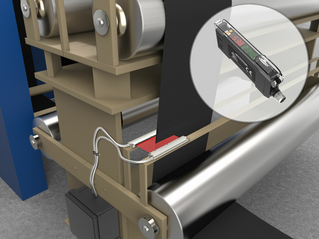

Edge Guiding in Battery Manufacturing

- Lithium battery assembly combines rolls of anode, cathode, and separator film into a larger roll of battery cell material.

- Misalignment of the three materials can cause material waste, jam the machine, or worse, result in recalls or a faulty final product. Even small variation to the left or right can be costly.

- Pairing Banner Engineering's DF-G3 Series fiber optic amplifier with a fiber array creates a high power fiber optic assembly that detects the slightest movement in either direction.

- Tight beam spacing and consistent light intensity across the entire array enable the fiber optic assembly to precisely detect very slight shifts in the rolls of film.

- When edges are not aligned properly, the machine automatically adjusts position to keep the film aligned.

Measuring Light Grid

- IO-Link, Modbus-RTU, and RS-485 models are available

- Applications include edge and center-guiding, loop tension control, hole sizing, parts counting and on-the-fly product sizing and profiling.

- Closely spaced infrared beams detect objects as small as 5 mm wide edge resolution is 2.5 mm.

- Controller functionality is built into the receiver, so basic setup requires no controller, software, or PC

- Configuration options include 14 measurement modes, three scanning methods, two analog and two discrete outputs and a serial output.

- Range is 4 meters.

- Array heights range from 150 to 2400 mm.

High Power Fiber Optic Sensor

Developed to provide world-class long-range detection, DF-G3 fiber amplifiers are advanced sensors featuring dual digital displays for use with plastic and glass fiber optic assemblies.

- Models with IO-Link enable a point-to-point communication link between a master device and a sensor, facilitating remote monitoring, teaching, and configuration

- World-class long-range sensing capability, more than 3 m (10 ft) with opposed mode fibers

- Easy to read dual digital displays show both signal level and threshold simultaneously

- Simple user interface ensures easy sensor set-up and programming via displays and switches/buttons or remote input teach wire

- Cross-talk avoidance function allows seven inspections in dense sensing point applications

- Energy efficient light resistance enables stable detection in industrial lighting environments

- High-power amplifier with small core fibers enables precise position sensing of small components

- Multi-function remote wire allows control of the LED, outputs, remote teach input, and cross-talk avoidance.

- Operator control of the sensitivity (hysteresis) provides additional detection sensitivity, or a stabilized output depending on the application details

- Lever action fiber clamp provides stable, reliable, and trouble-free fiber clamping

- Expert TEACH and SET methods ensure optimal gain and threshold for all applications, especially for high speed or low contrast applications