Our most popular indicator light. The 50 mm general-purpose indicator is available in both AC and DC supply voltage options.

- Rugged, cost-effective and easy-to-install indicators

- The illuminated dome provides easy-to-see operator guidance and an indication of equipment status

- Compact devices are completely self-contained — no controller needed

- 18 to 30V dc operation 85 to 130V ac operation

- Displays up to three colors

- Immune to EMI and RFI interference

Downloads

Technical Literature

Technical Literature Audible

Brochures & Catalogs Audible

Application Notes

Tank Farm Monitoring

With a Sure Cross Wireless Network, FlexPower Nodes are deployed at each tank without the need to run cables for power or I/O data transmission. Banner’s unique power management capability enables a Node equipped with an ultrasonic analog level sensor to operate for years on a single DX81 battery power supply. A DX80 FlexPower Node offers a combination of discrete and analog I/O in a single package, eliminating the need for time-consuming manual data collection.

Monitoring Operator Efficiency in a Printing Facility

A cardboard goods printer struggled with an inability to track machine operators’ efficiency and performance as measured against standard production rates.

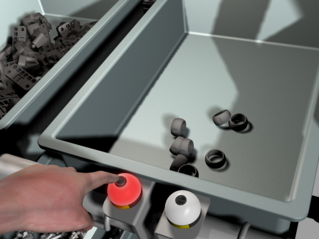

Call for Parts (Put to Light)

When the supply of parts runs low, the assembler presses the EZ-LIGHT K50 push button to the left, which is used as a call button to signal to the runner to bring more parts. The K50 light to the right is used as a part-pick indicator.

Operator Guidance Solution

A Henshaw customer manufactures drivetrain and powertrain systems for the automotive industry. The company had experienced productivity losses due to errors in the assembly of transmission valve bodies. Henshaw was tasked with developing a system that would reduce errors and improve the assembly process.

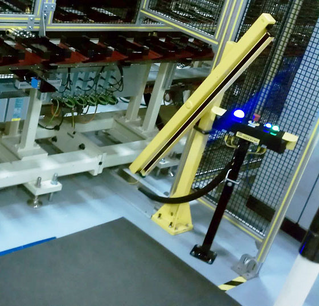

Run Bar Provides Operator Guidance

A leading machine manufacturer builds workstations designed for accurate, timely and cost-effective battery cell assembly. A value added component of the workstations is an operator guidance device that does three jobs: enables assembly processes to start and stop, indicates parts to be picked and installed, and completely stops line operation if emergencies occur. When it became too costly for the OEM to construct and mount these devices themselves, they turned to Banner to craft an all-inclusive solution. To honor the time line requirements of their customer—a major tier two battery supplier—the OEM needed the solution in eight weeks.

Wireless Call for Parts

A system of Banner’s TL70 wireless modular tower lights and K50 touch buttons provides an efficient, easy way to communicate a call for more parts with a forklift driver. When a workstation is almost out of cartons, the operator touches the ergonomic K50 touch button which changes the status on the connected TL70 wireless tower light to red.

Part Loaded Indicator

Before the EZ-LIGHT K50L indicator light was installed, the operator would place a part on the machine and then step out of the work area to check the stack light to see if the part was loaded properly. If not, the operator had to repeat the set-and-check process before initiating the machine's action on the part. Since the K50L was installed inside the workstation, using a simple Y splice, the operator can tell immediately if the part is correctly placed.

Checkweigh Station Indication of Pass/Fail Status

Harsh washdown environment, alert operators of fail status

Status Indication on Driverless Vehicles

The K50L domed 50 mm indicator light works well for status indication on autonomous shuttle buses. The buses operate on short distances in outdoor environments that exposed the bus technology to a variety of weather conditions. The rugged K50L indicators are rated IP67 and IP69K to withstand water ingress in the harsh environment.

Car Wash Status Indication Inside Washing Area

Bright indication inside a car wash for various stages