Smarter Sorting: A Simple Fix to Address 40% of Conveyor Jams

A green light signals to workers that packages are moving smoothly, meaning packages can be placed in the chute.

Challenge

At a high-volume sort facility, stopped belts caused by package buildup are made worse when workers mistakenly send more packages down chutes to those belts. This happens because workers must look away from their work area to check a distant stack light that indicates belt status, then match it to the correct chute. A green light means the belt is moving and packages can be placed. Red means the belt is stopped and packages should not be placed. The process is prone to errors, and when mistakes happen, packages pile up on stopped belts, creating slug formations that account for 40% of all jams, leading to wasted time, potential equipment damage, and safety risks for workers clearing the backups.

Solution

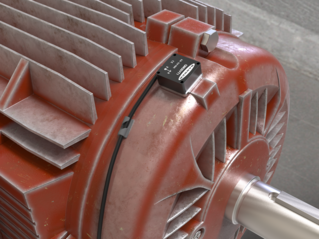

Banner worked with a team at the sort facility to develop a solution that would simplify their process, reduce errors, and ensure clear, real-time chute status exactly where it’s needed. The solution was built around the GS60 Pro Multicolor Guide Spotlight and a Q5X, which work together to help workers make faster, more accurate placement decisions.

A red light signals to workers that buildup is detected, meaning packages should not be placed in the chute.

A Q5X was mounted to detect when packages build up at the bottom of a chute. It was then connected to the GS60 Pro via a splitter and powered through a standard power supply. When packages are moving smoothly, the light projected onto the chute is green, signaling to workers that they can place packages into the chute. When packages begin to accumulate, the sensor triggers the GS60 Pro to project a red light onto the chute, signaling workers to stop placing packages. Once the buildup clears, the light returns to green, signaling workers to resume placing packages.

This smarter solution allows workers to focus entirely on what matters: chute availability, not belt status. It eliminates the need to check a distant stack light, interpret belt status, and apply that information to a chute. Now, they simply look inside the chute for clear indication: a green light means they can place a package, and a red light means they cannot.

Featured Product

-

GS60 Pro Multicolor Guide Spotlight

Banner’s GS60 Pro Multicolor Guide Spotlight reduces errors and improves productivity via easily configurable illumination, indication, and operator guidance.

-

Q5X Series High Power, Multi-Purpose Photoelectric Sensor

A powerful, problem-solving sensor in a cost-effective device with industry-standard rectangular housing. With a range from 50 mm to 5 m, the Q5X provides reliable detection of the most challenging targets.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)