-

Applications

-

Quality Control

Quality Control

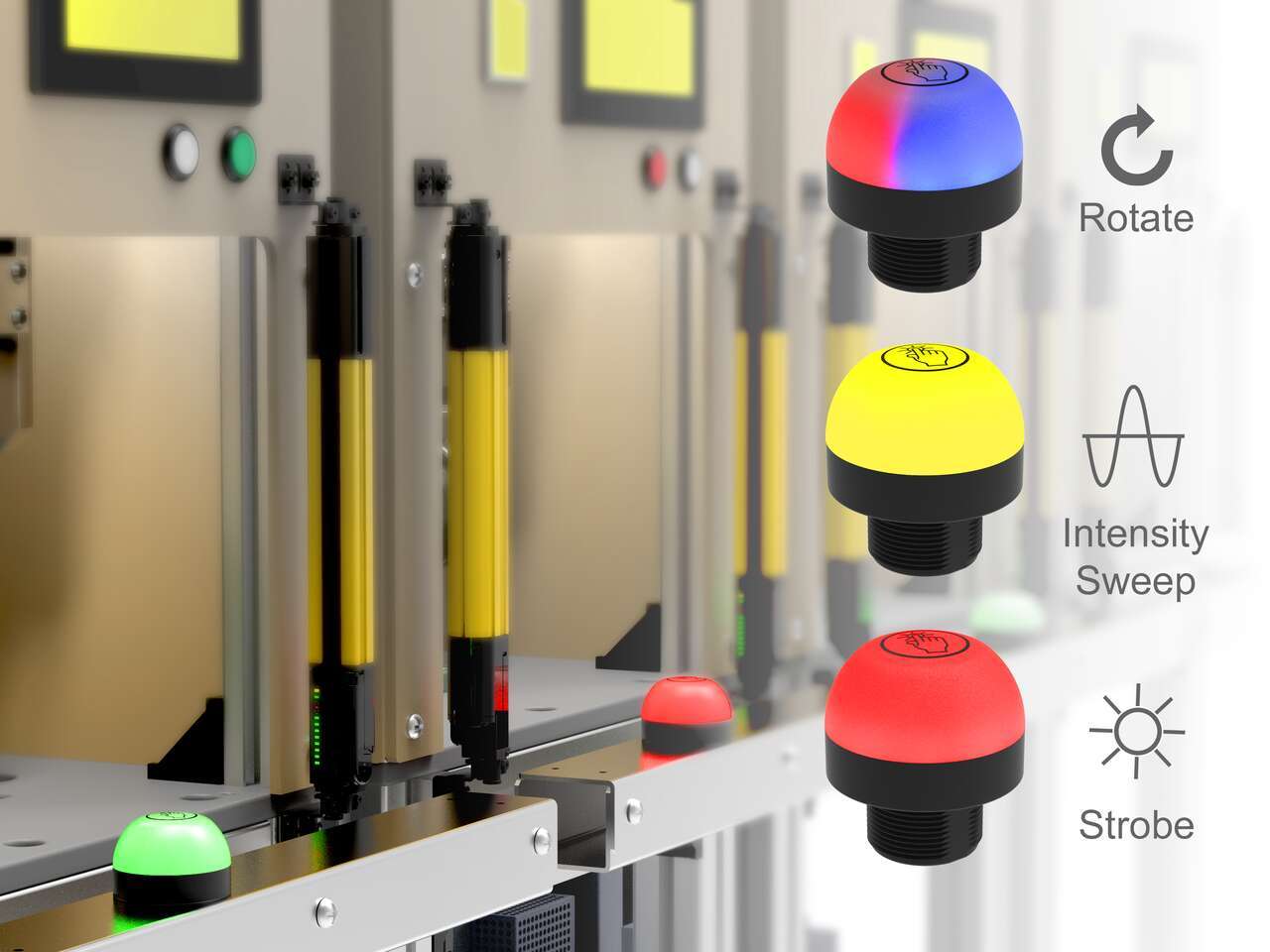

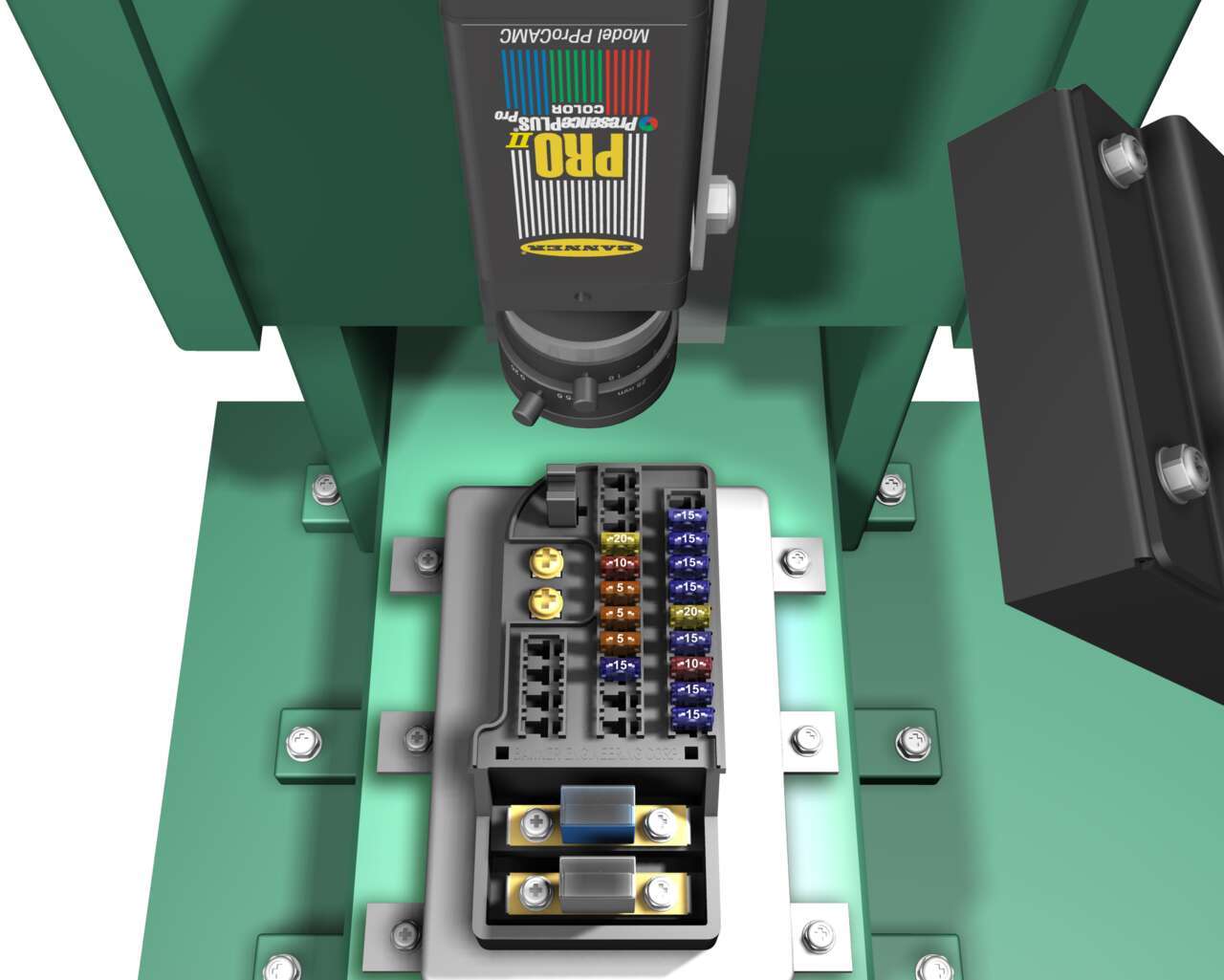

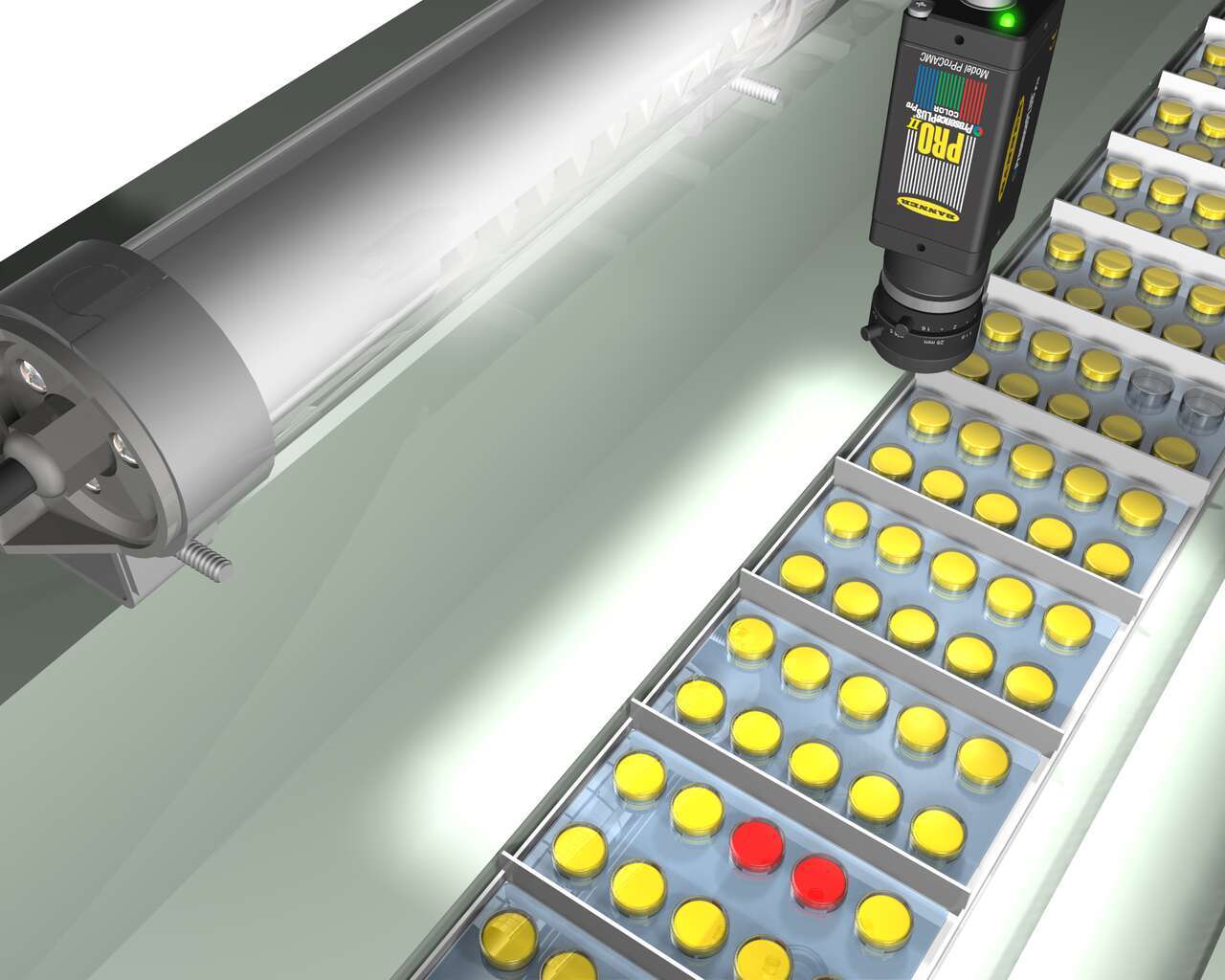

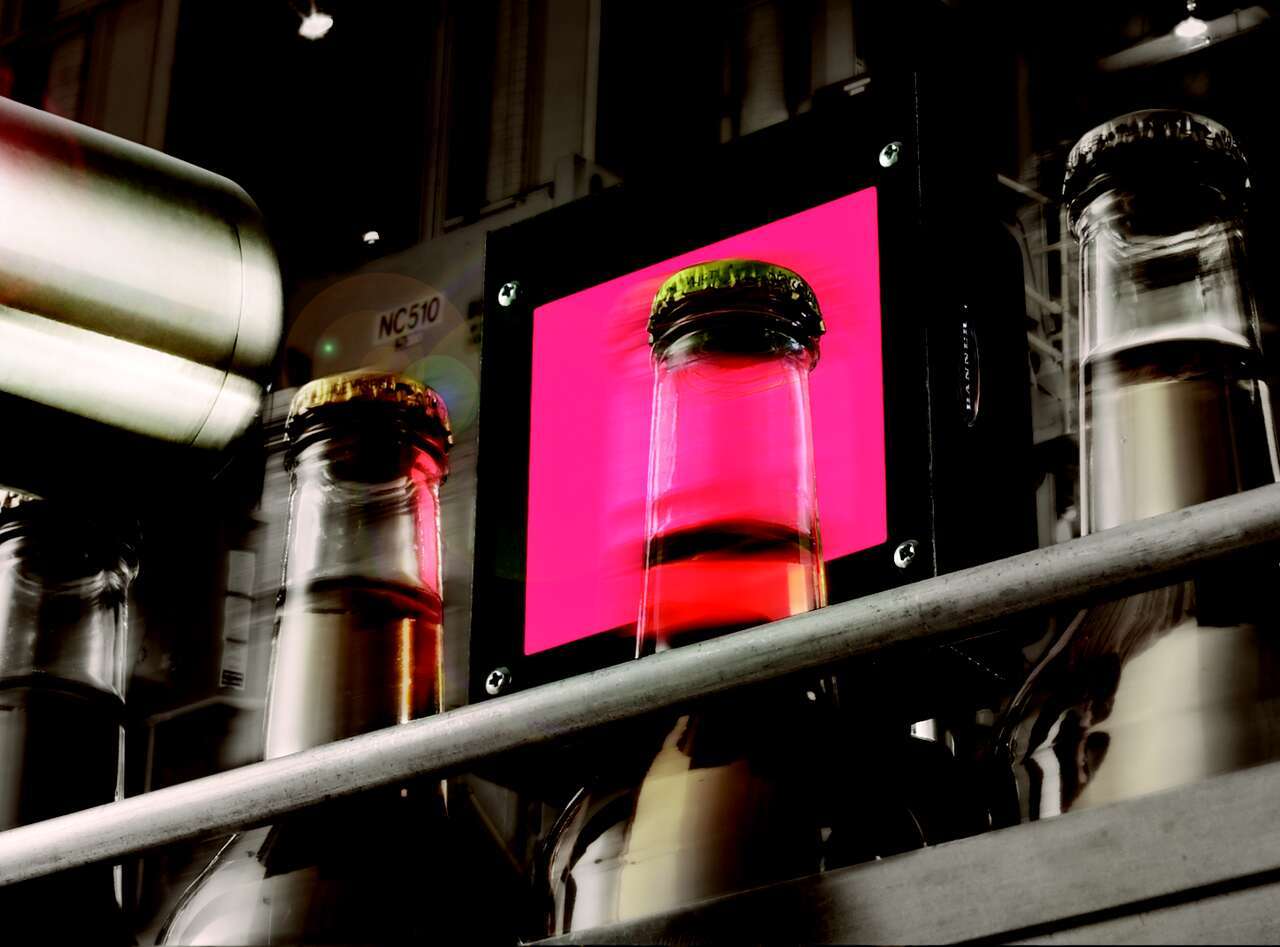

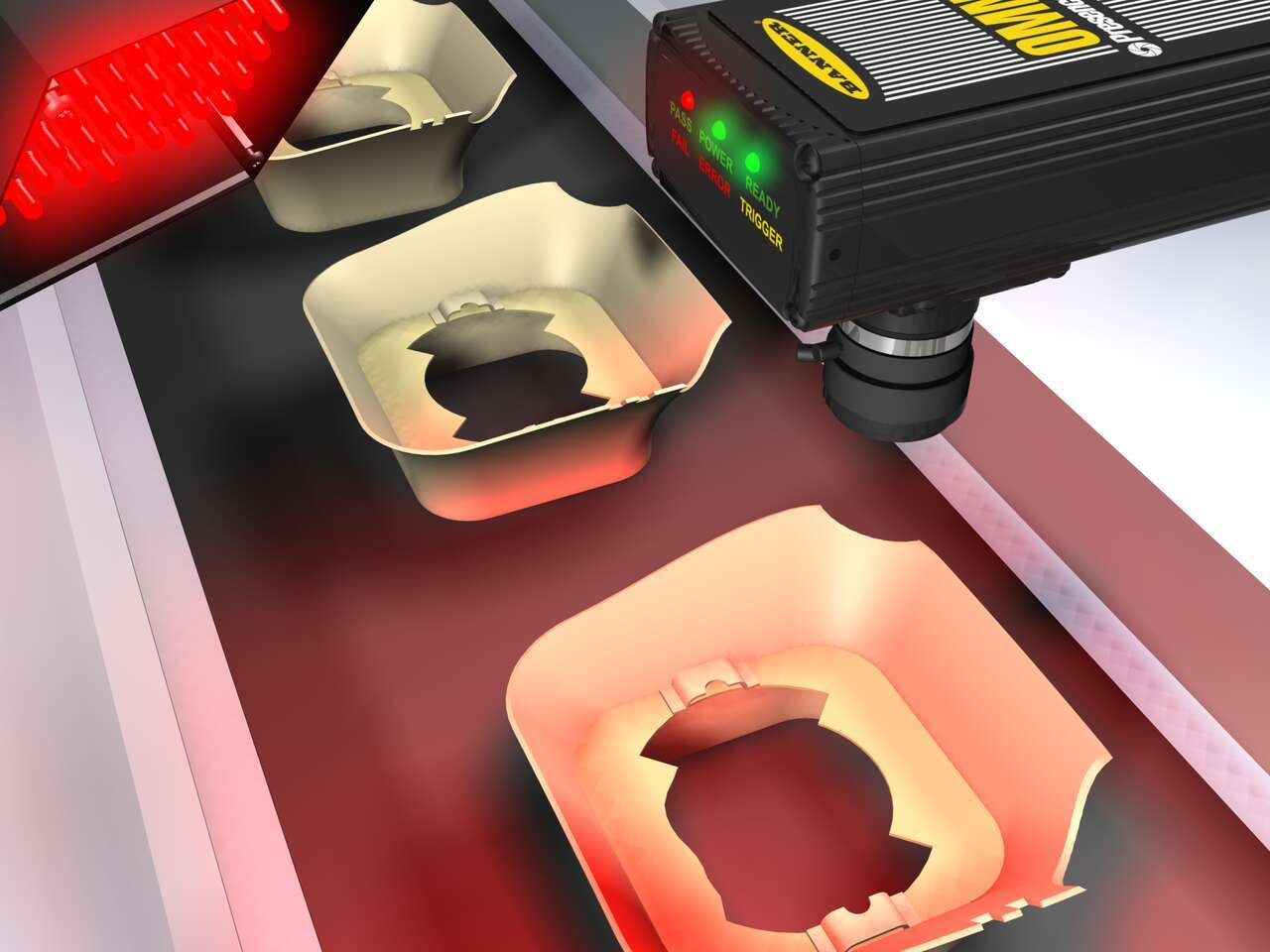

Improve Quality and Increase Efficiency Simultaneously

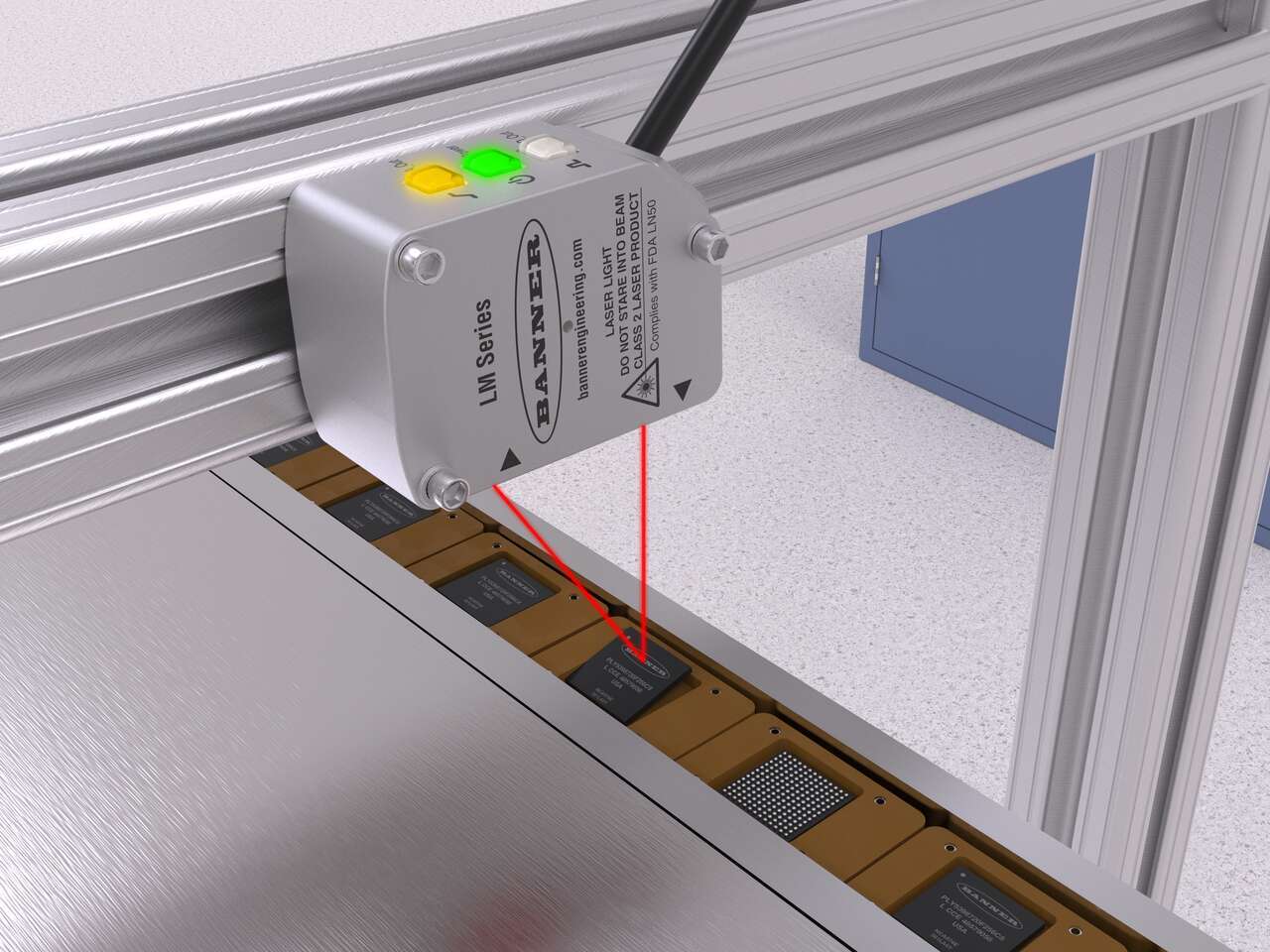

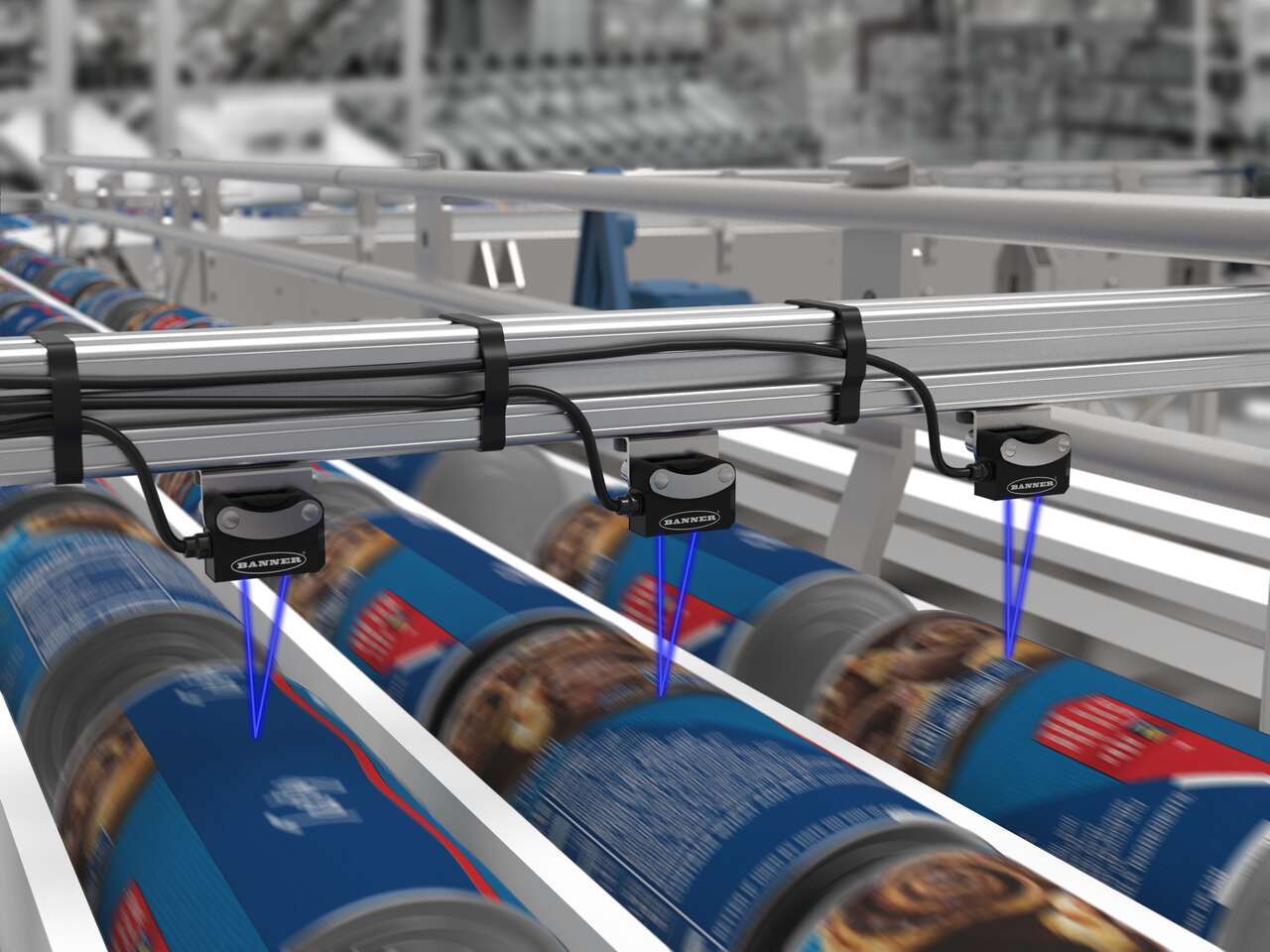

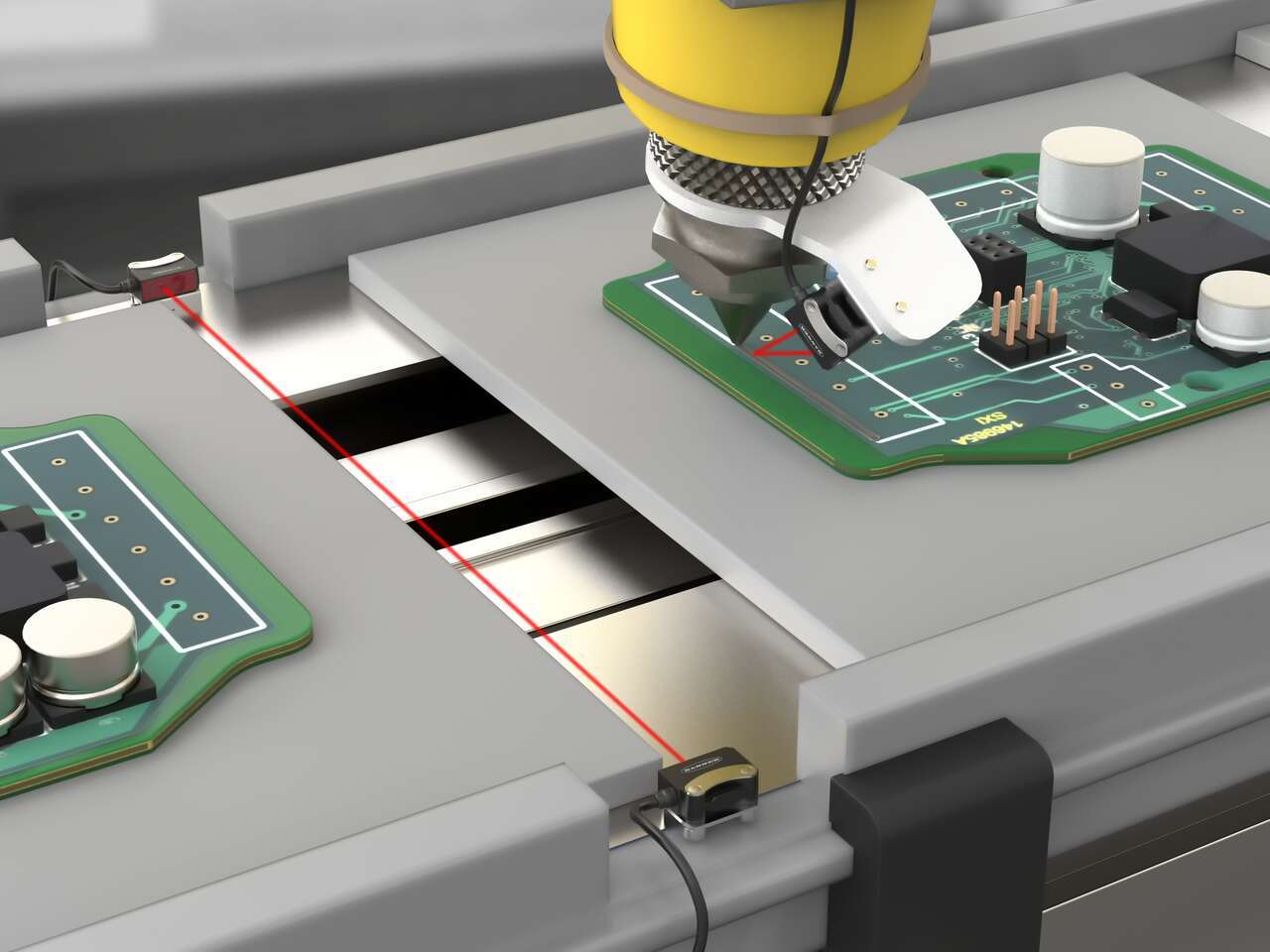

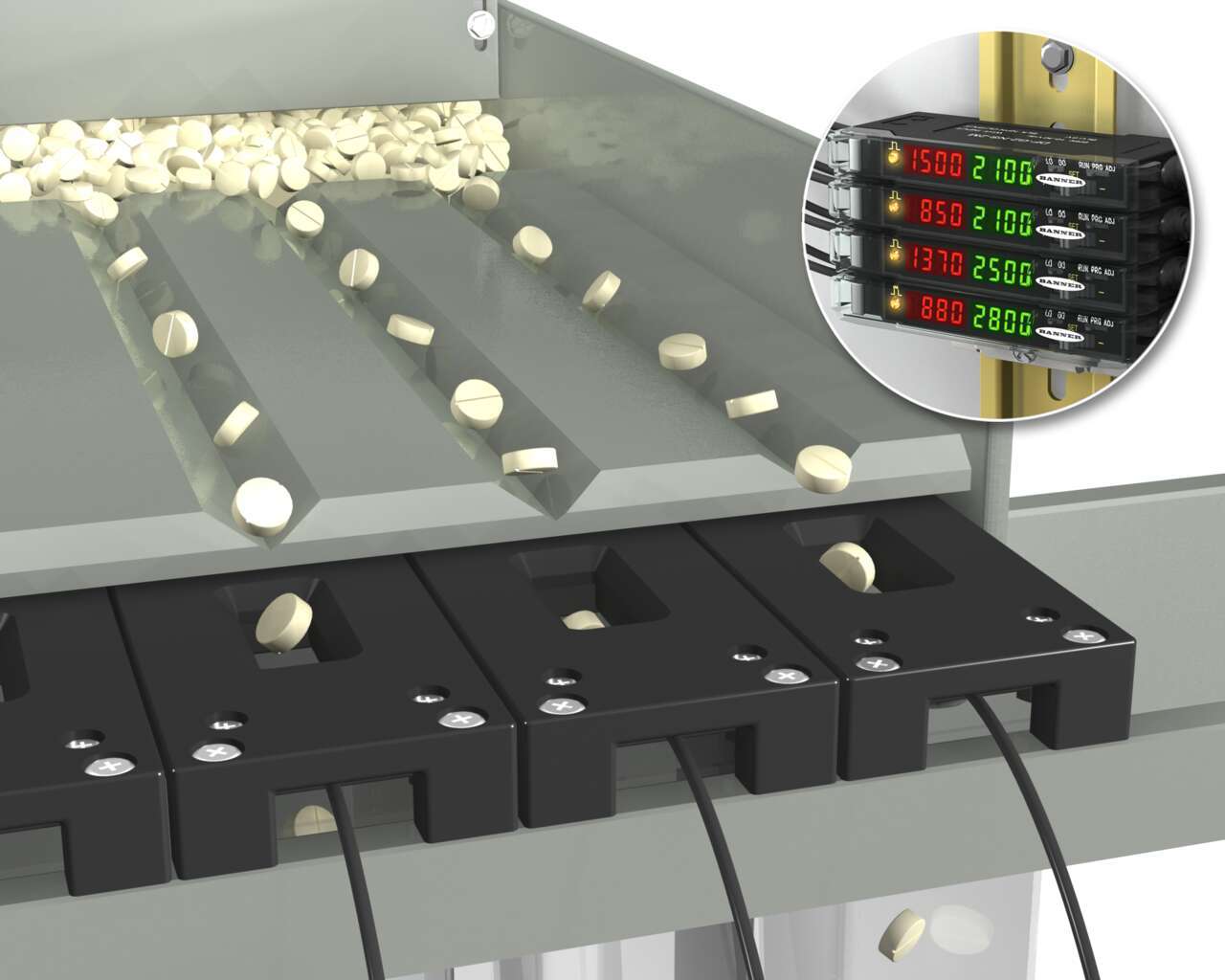

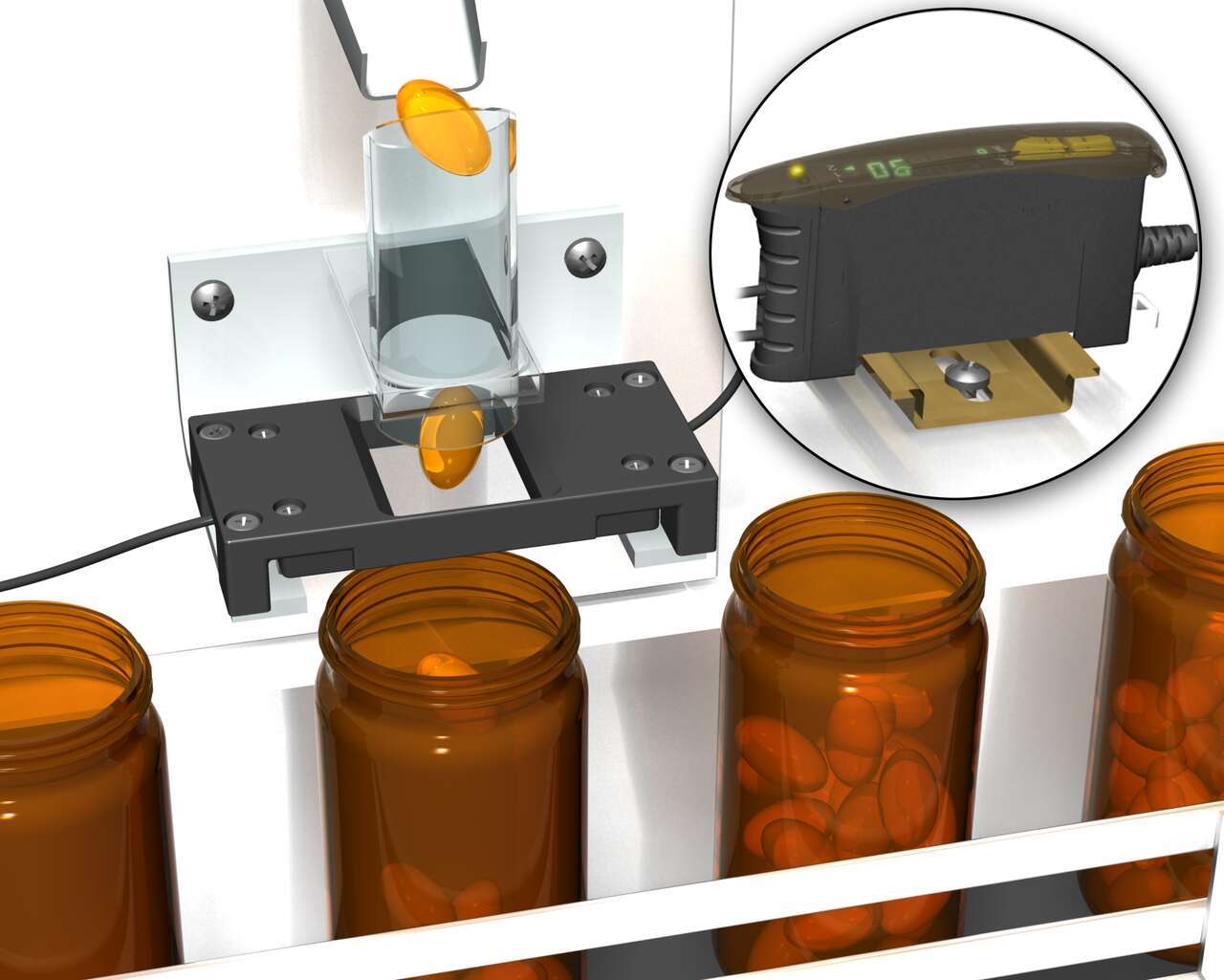

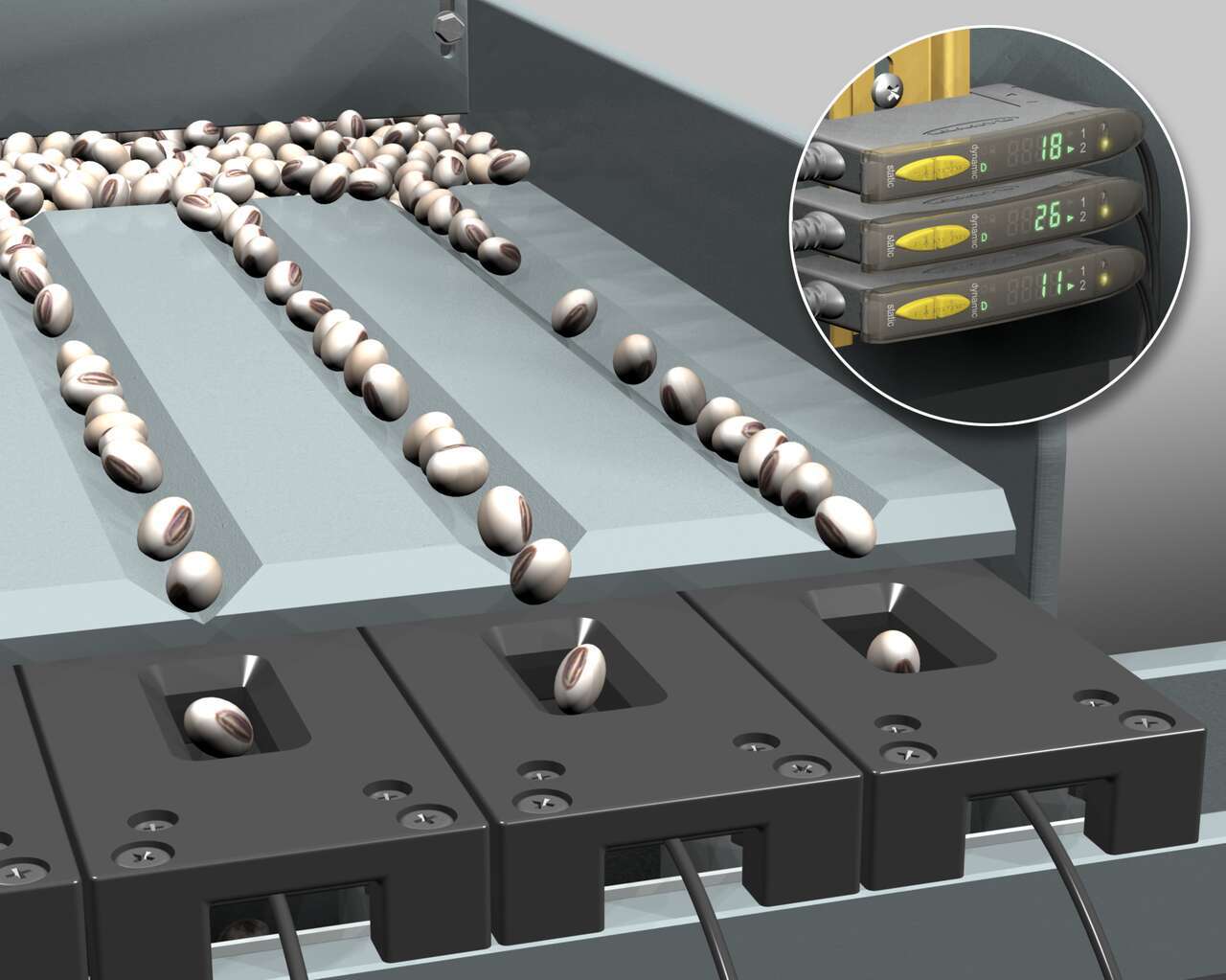

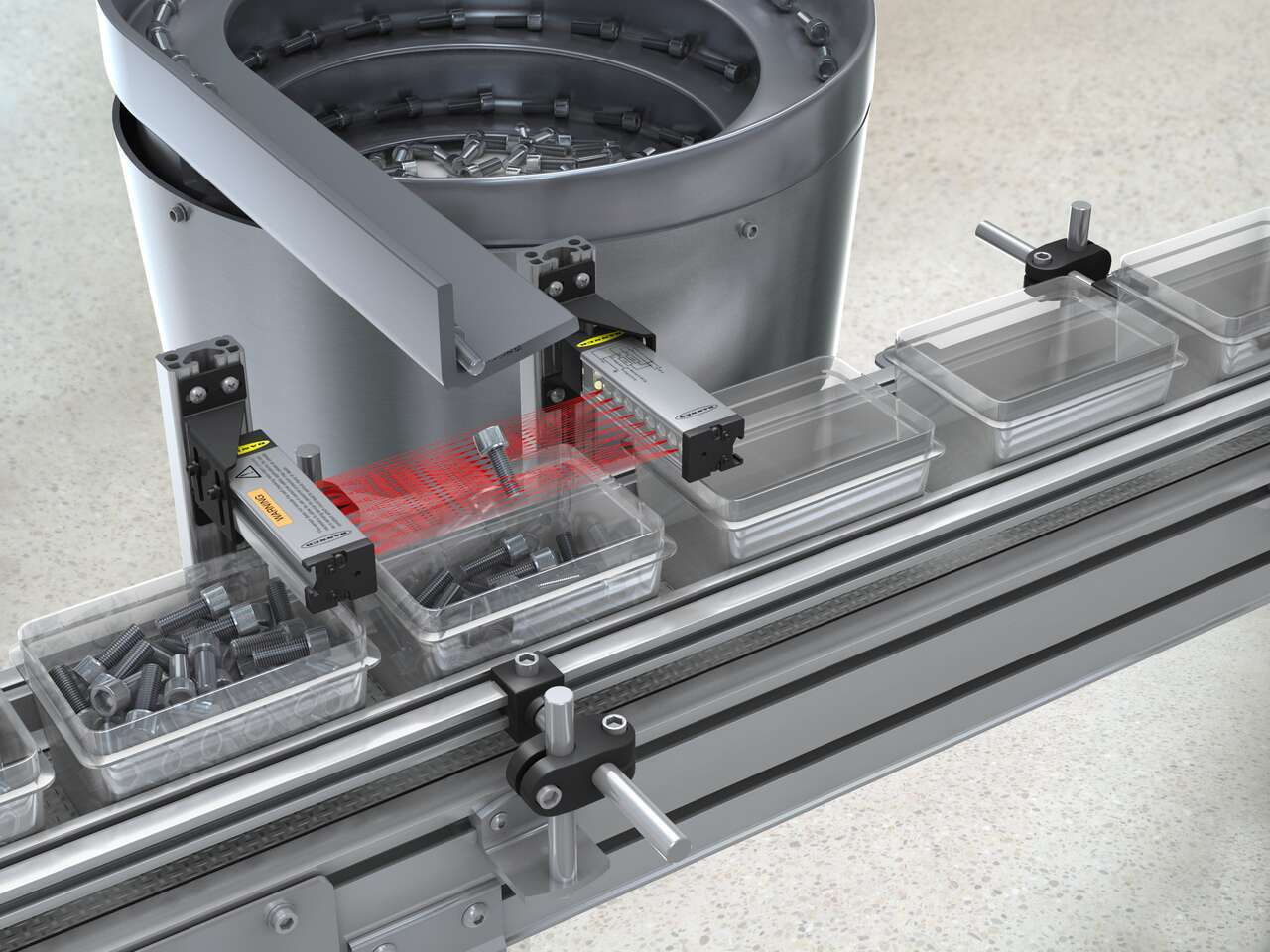

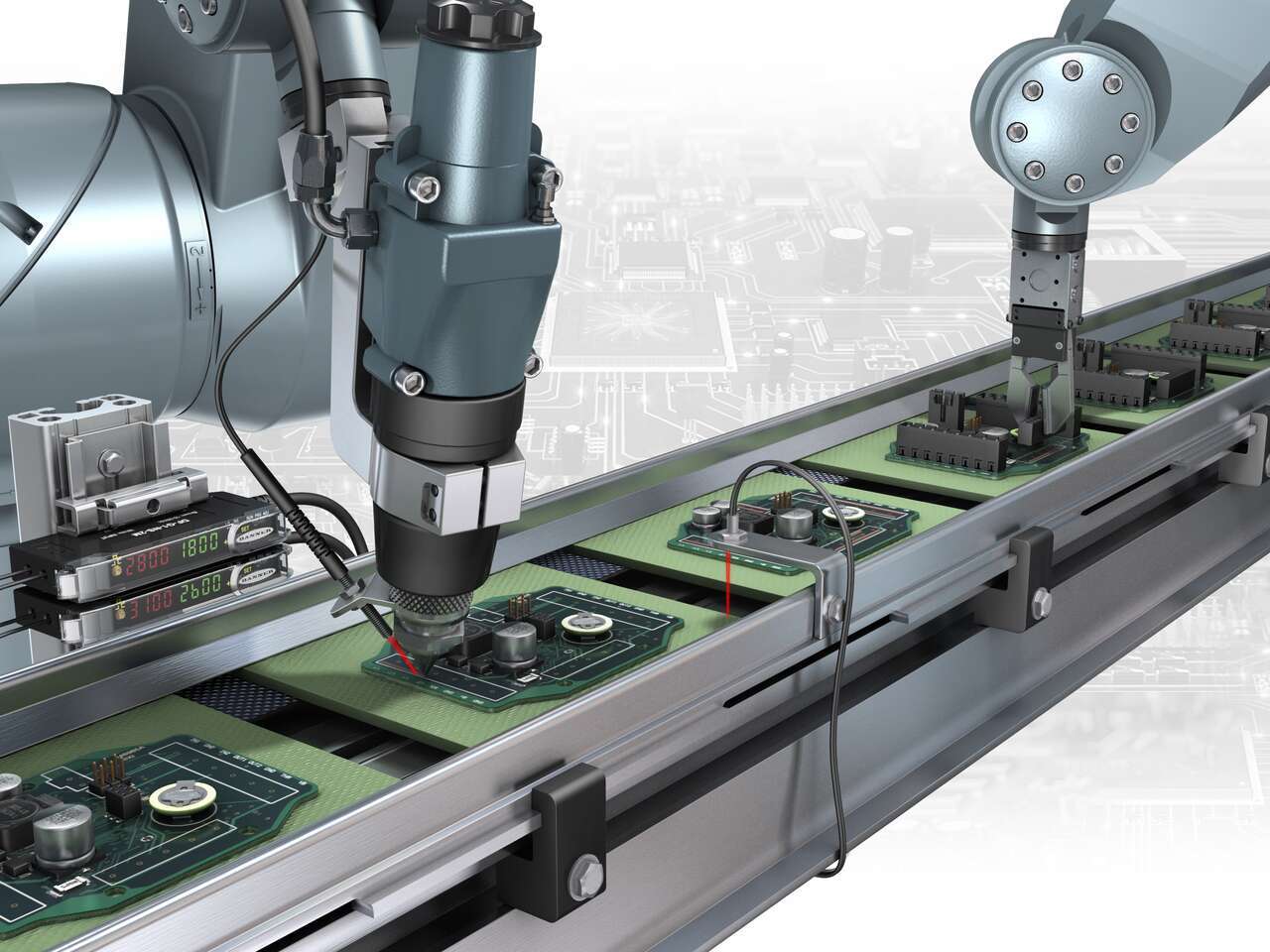

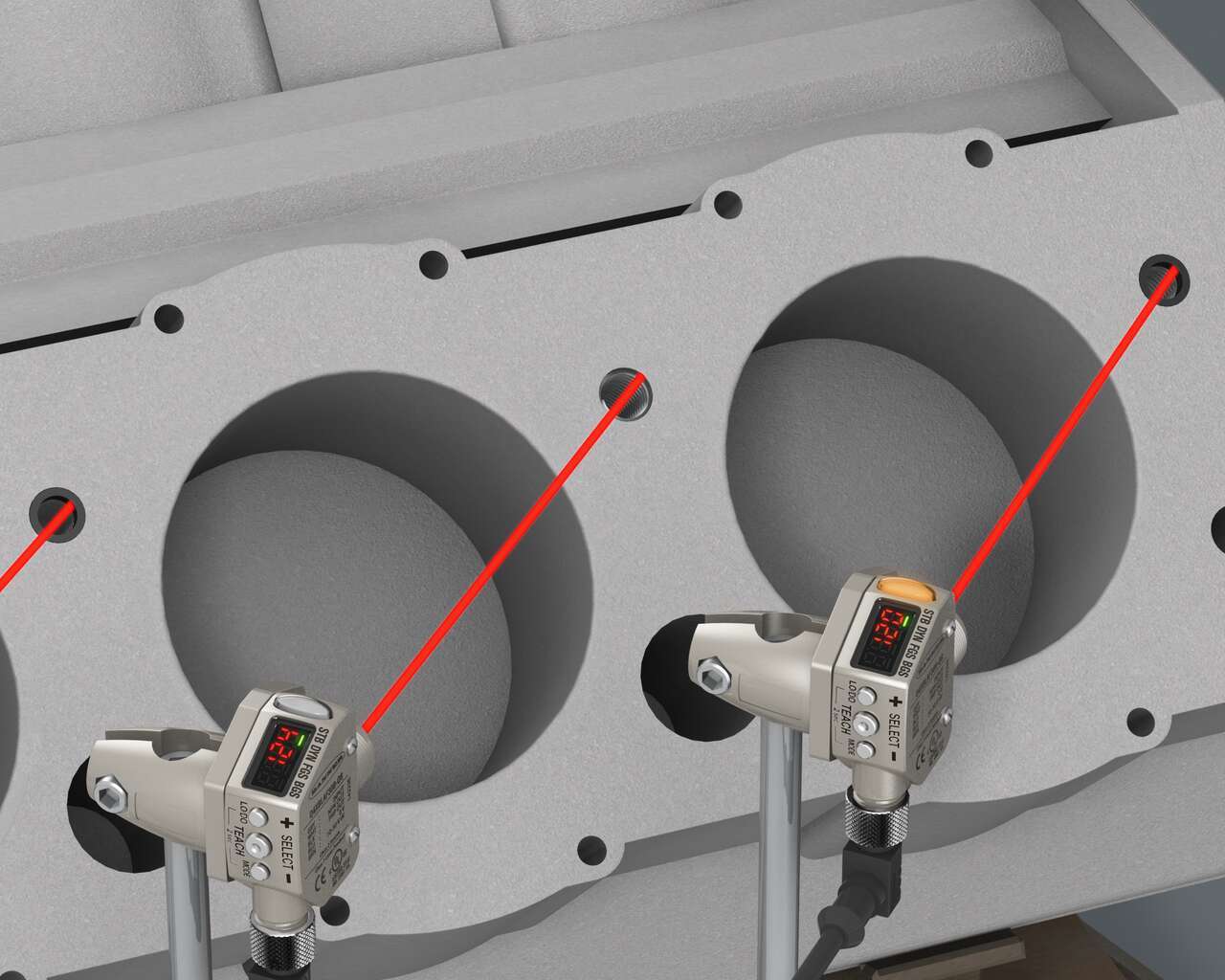

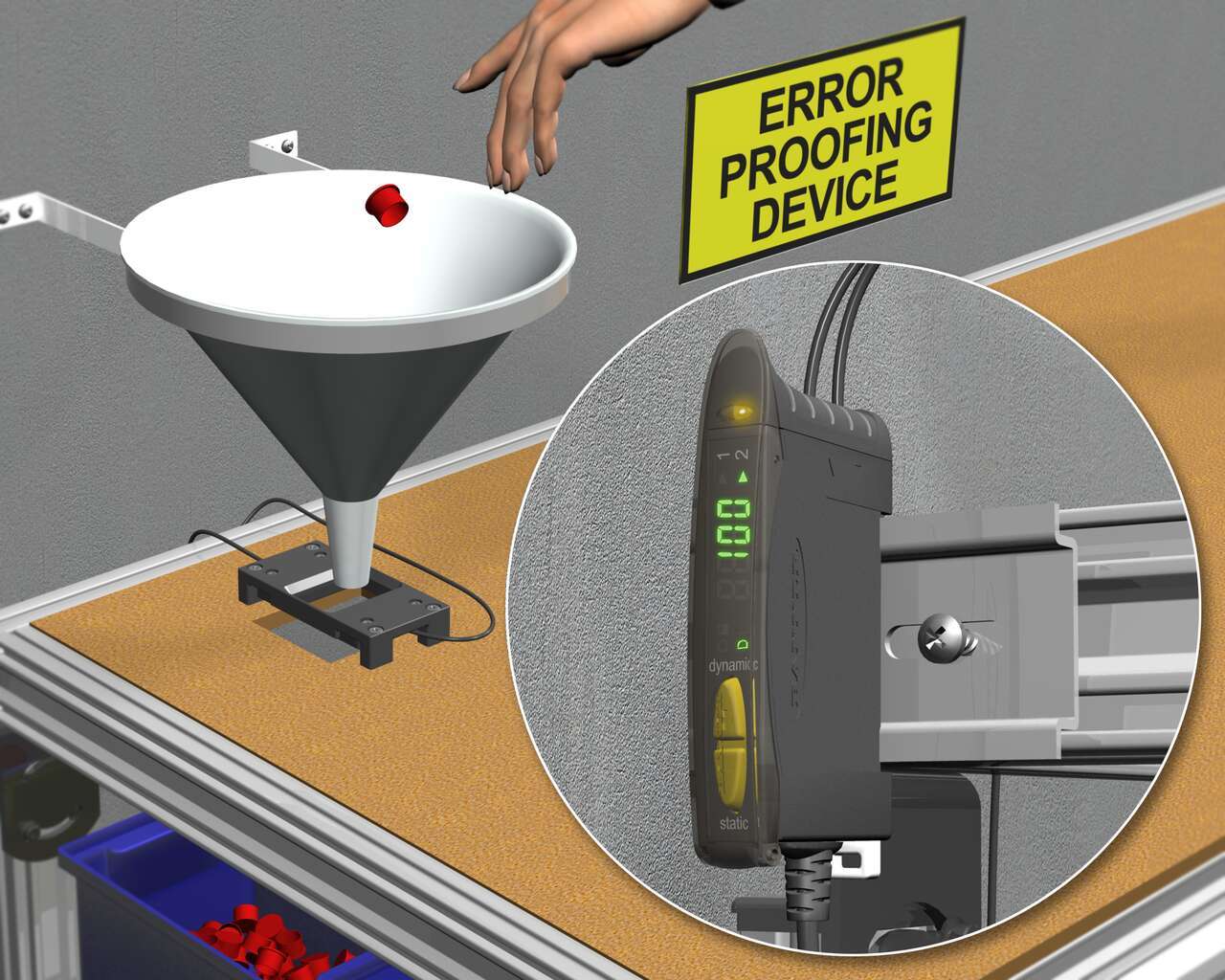

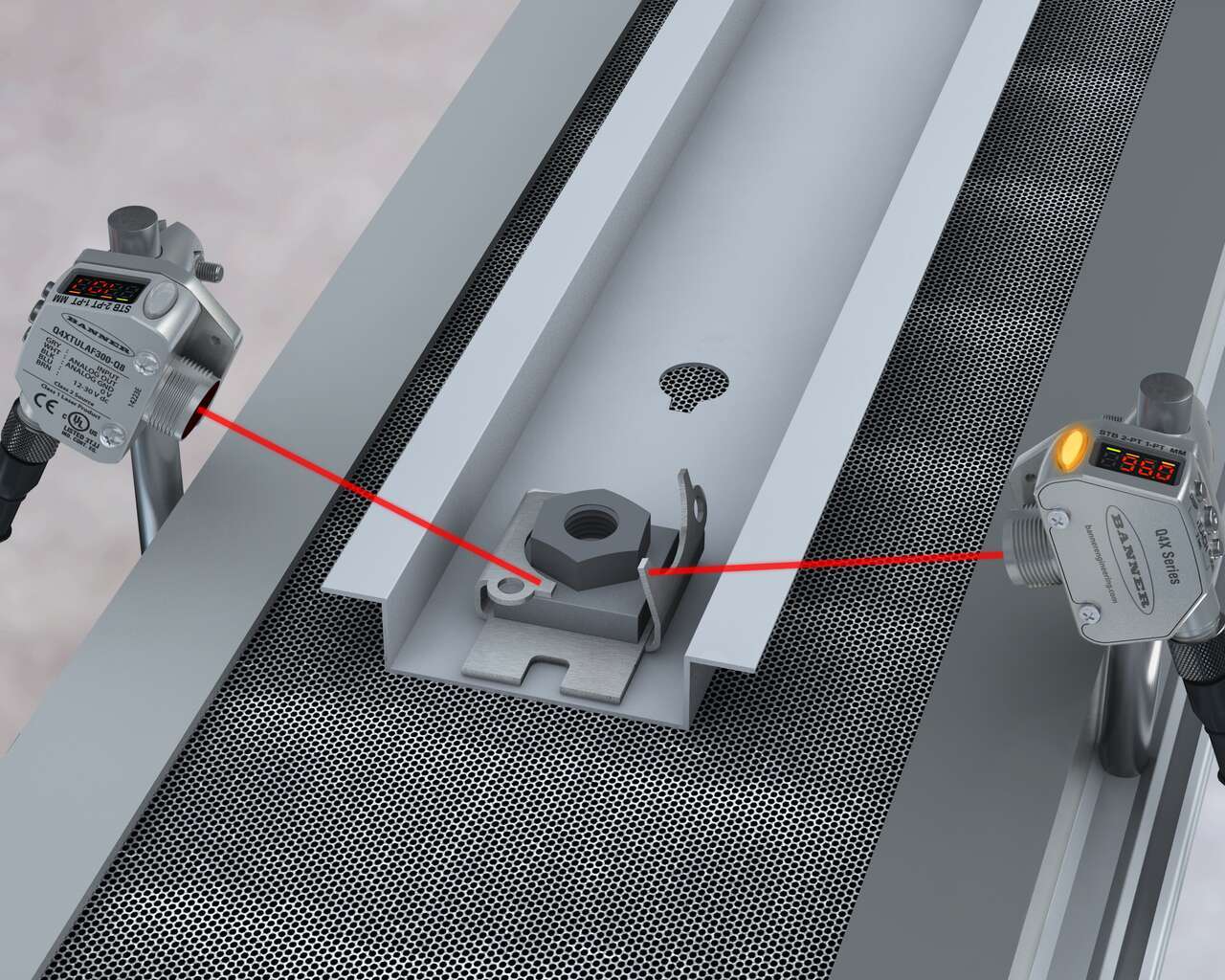

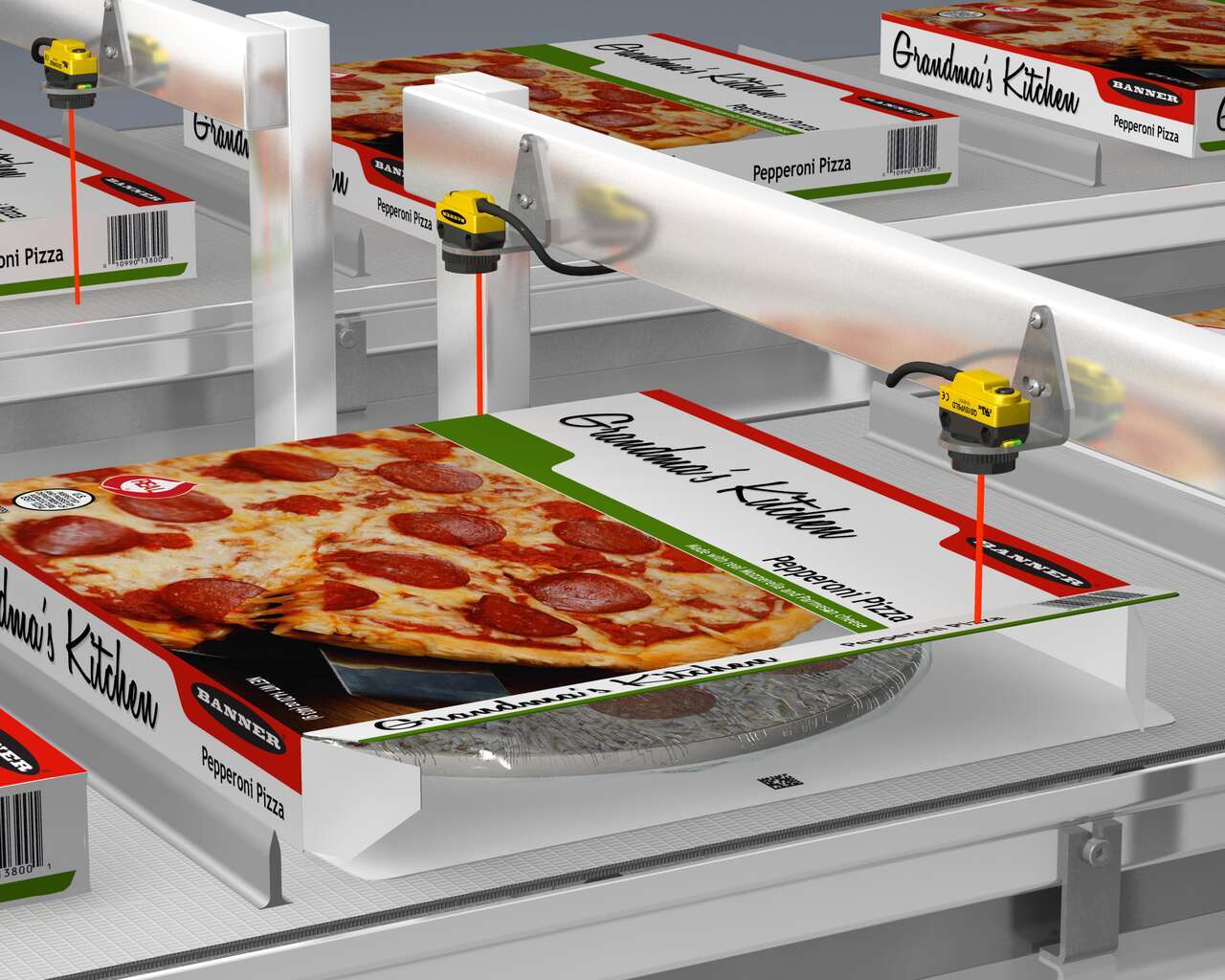

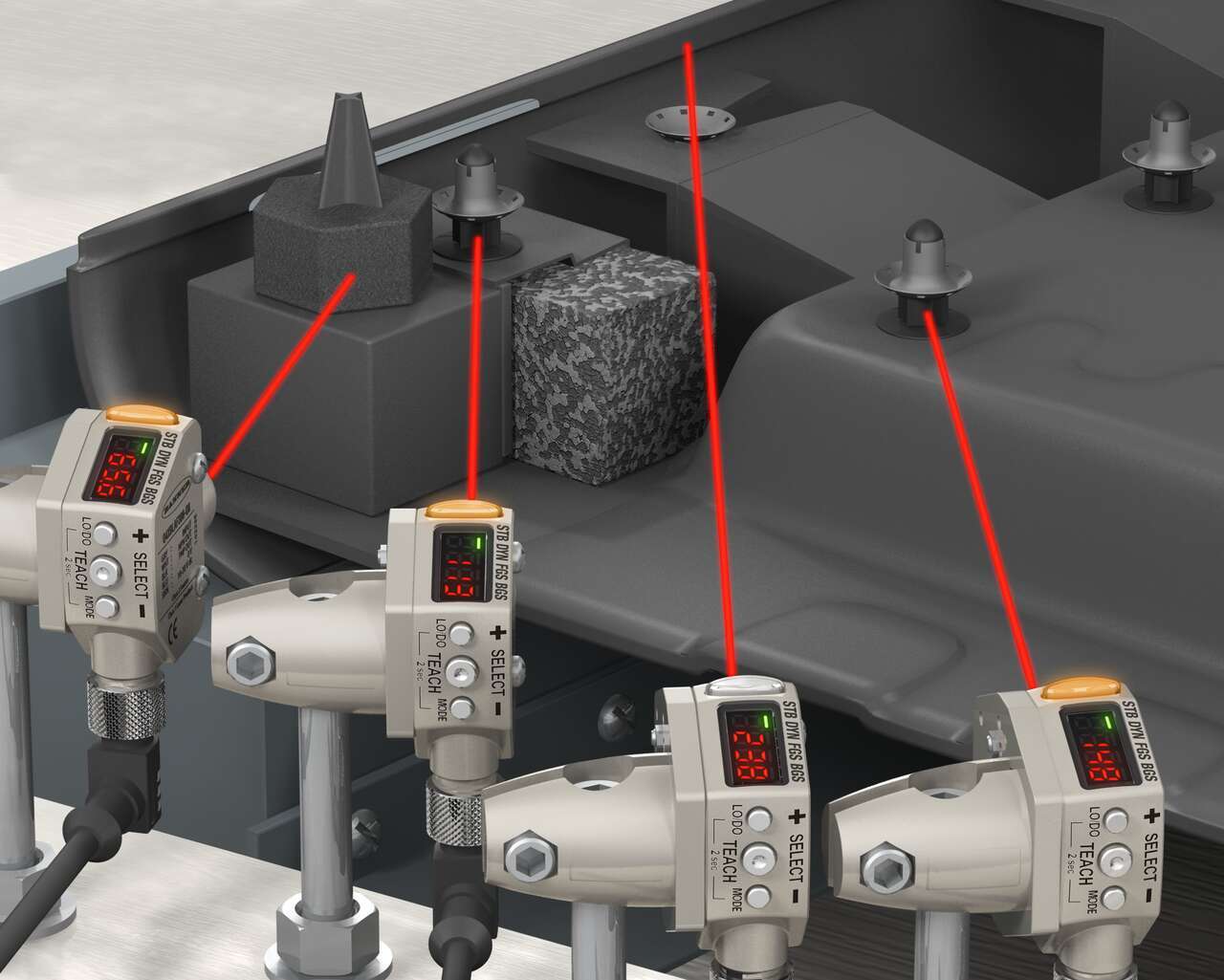

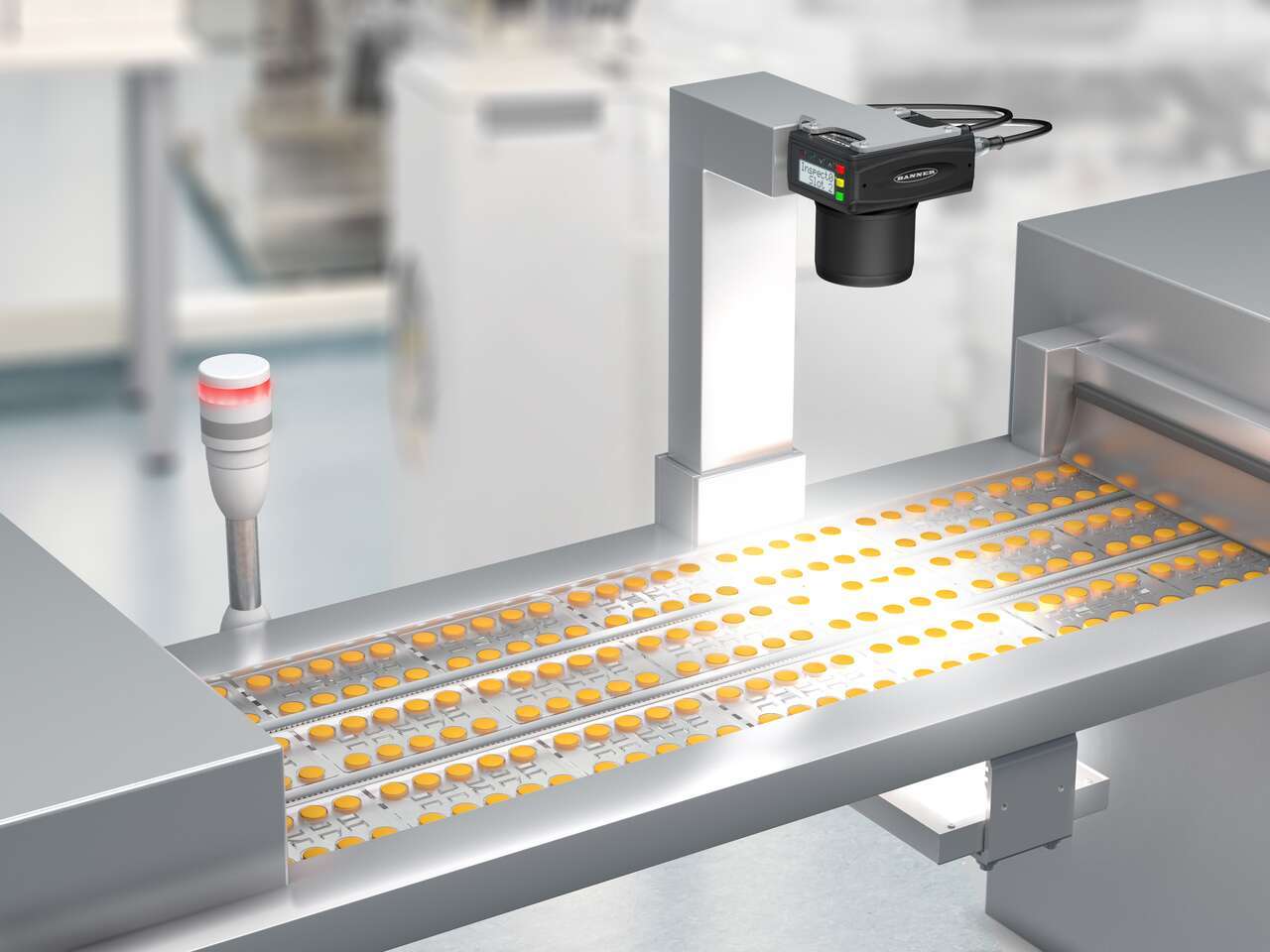

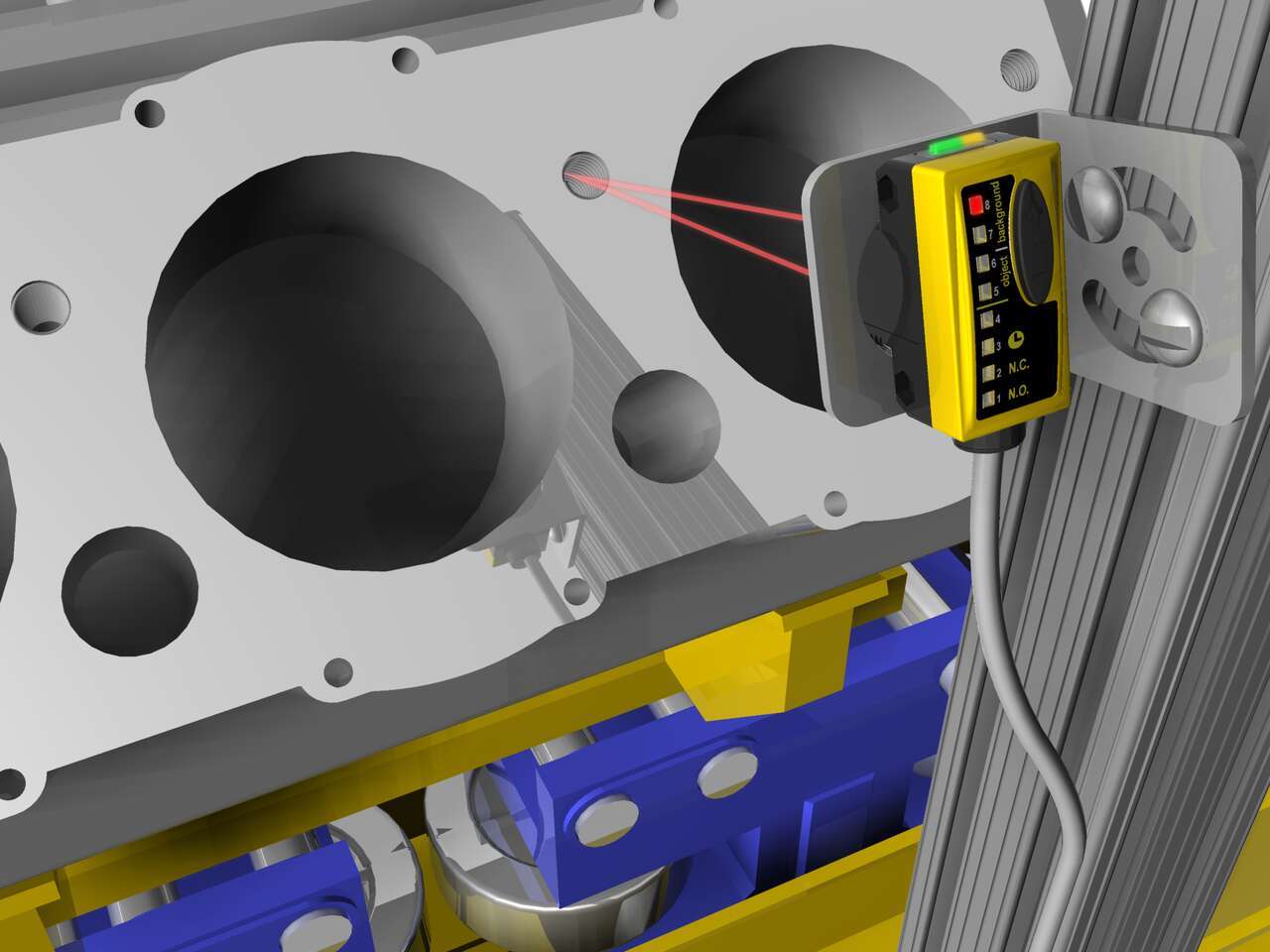

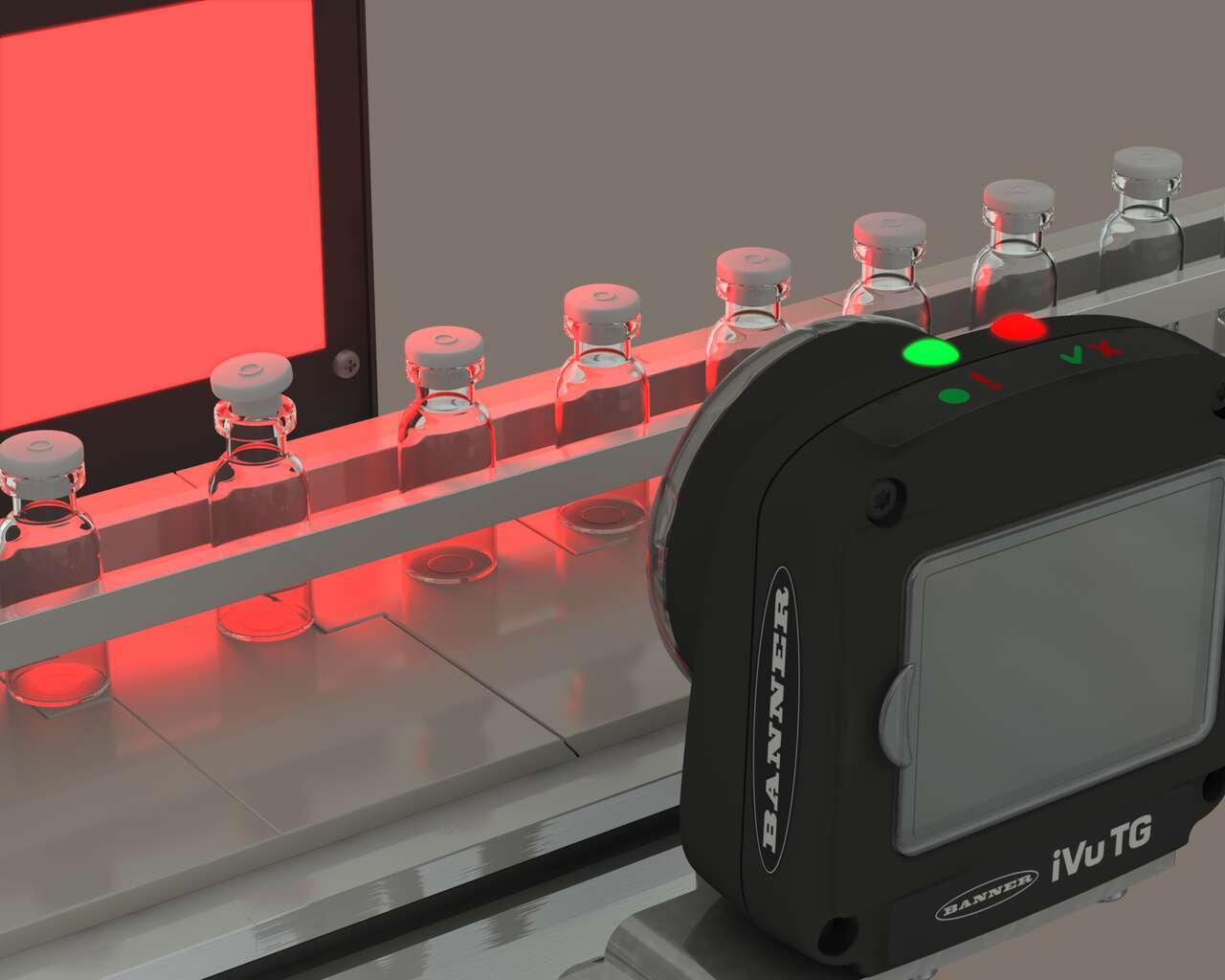

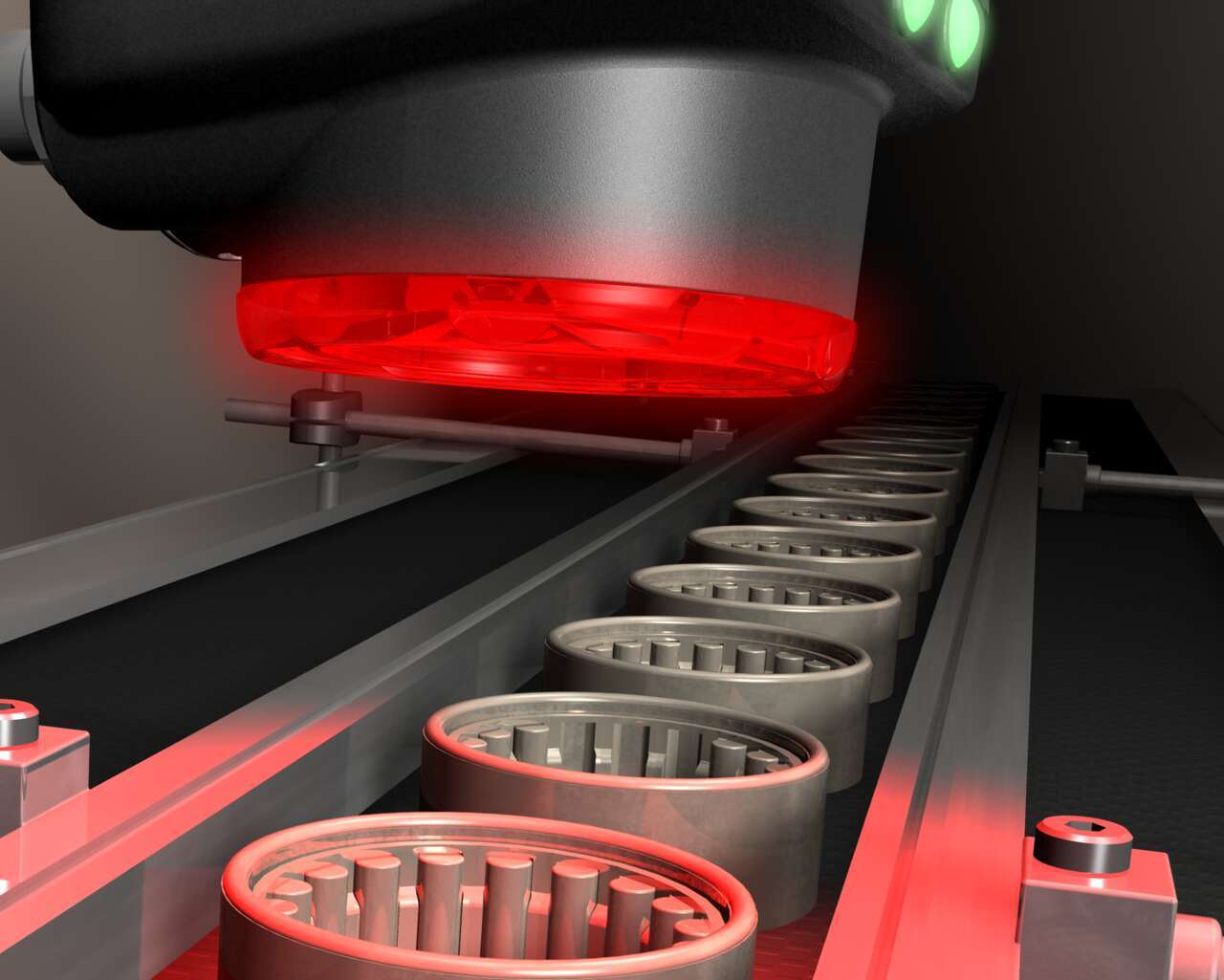

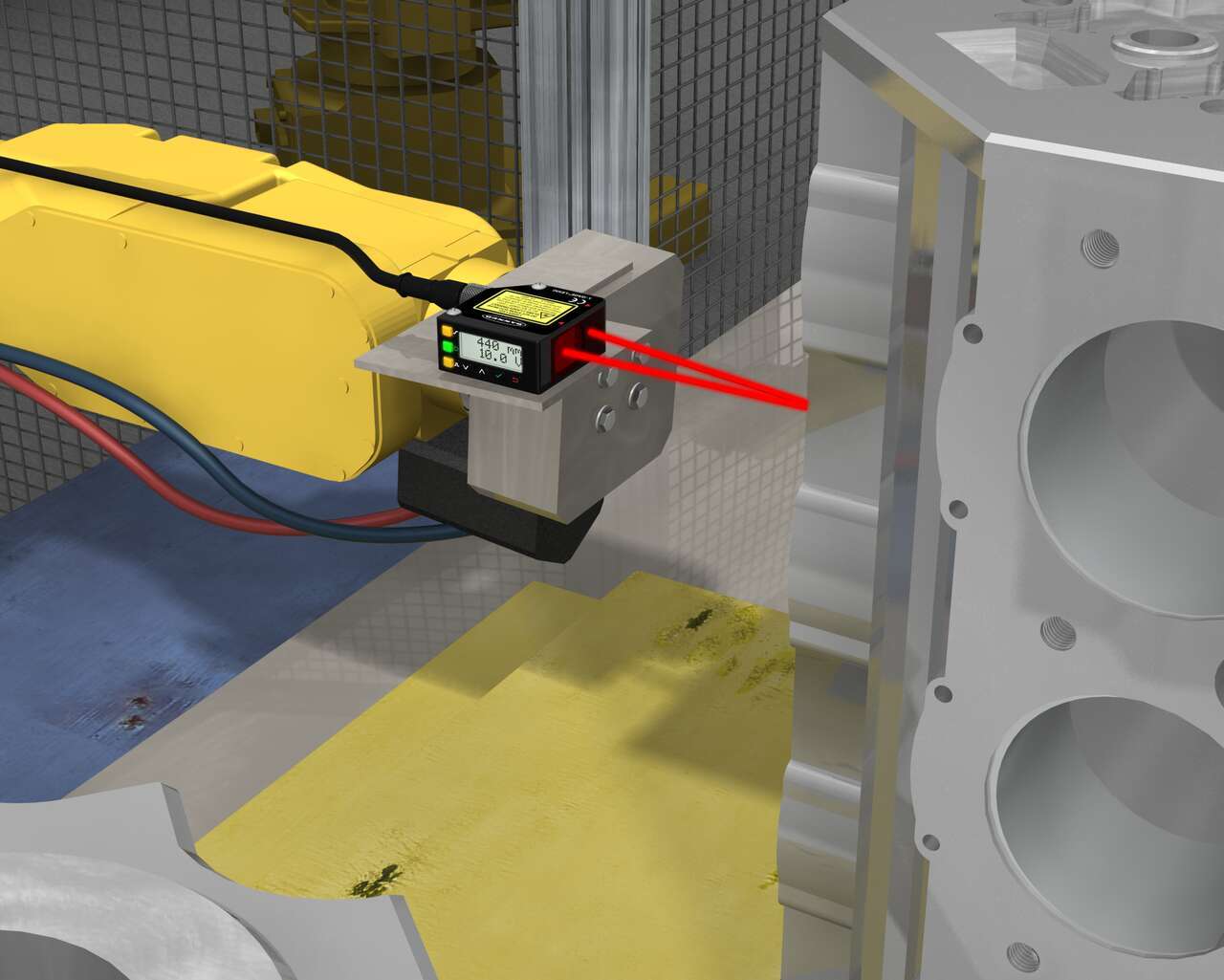

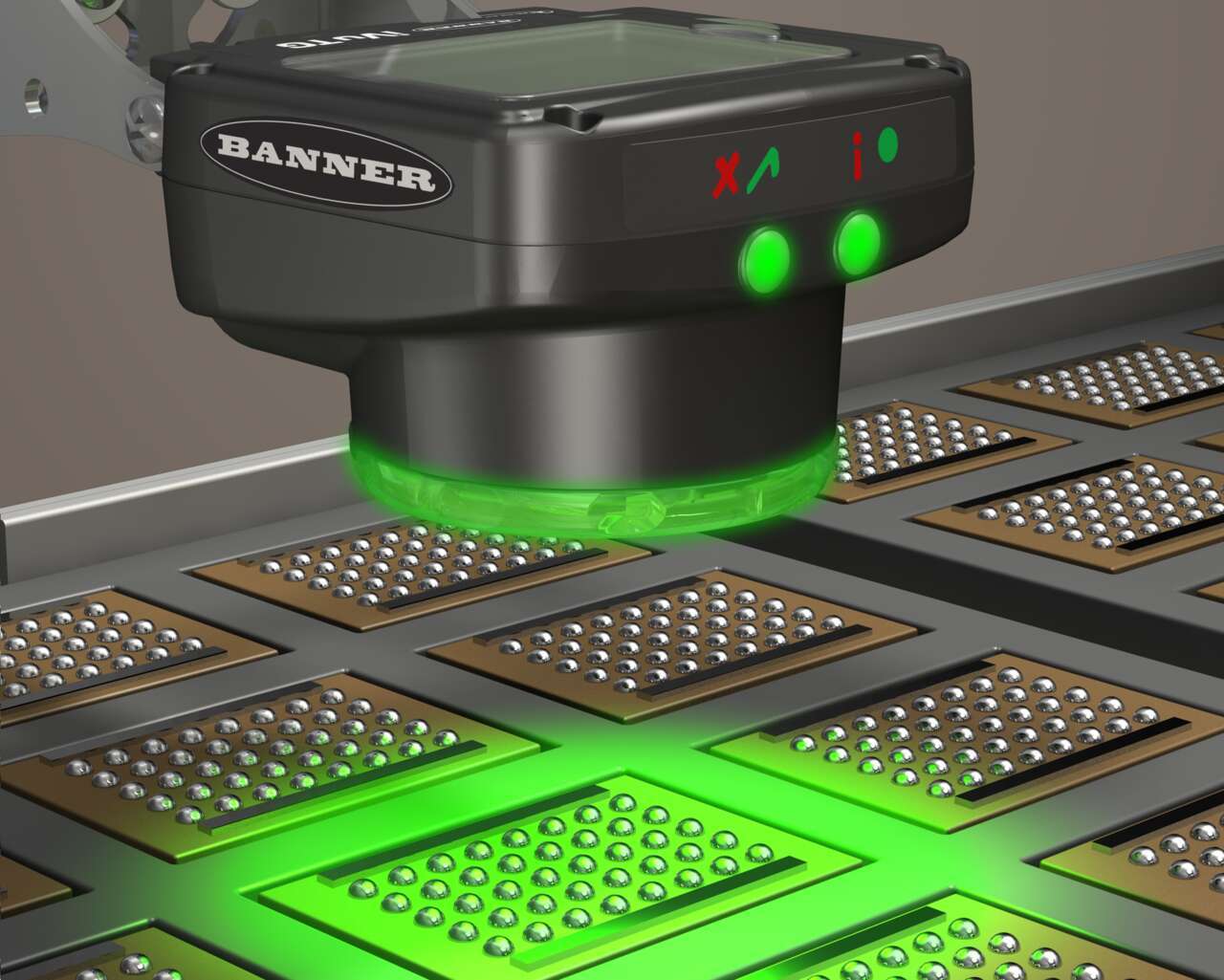

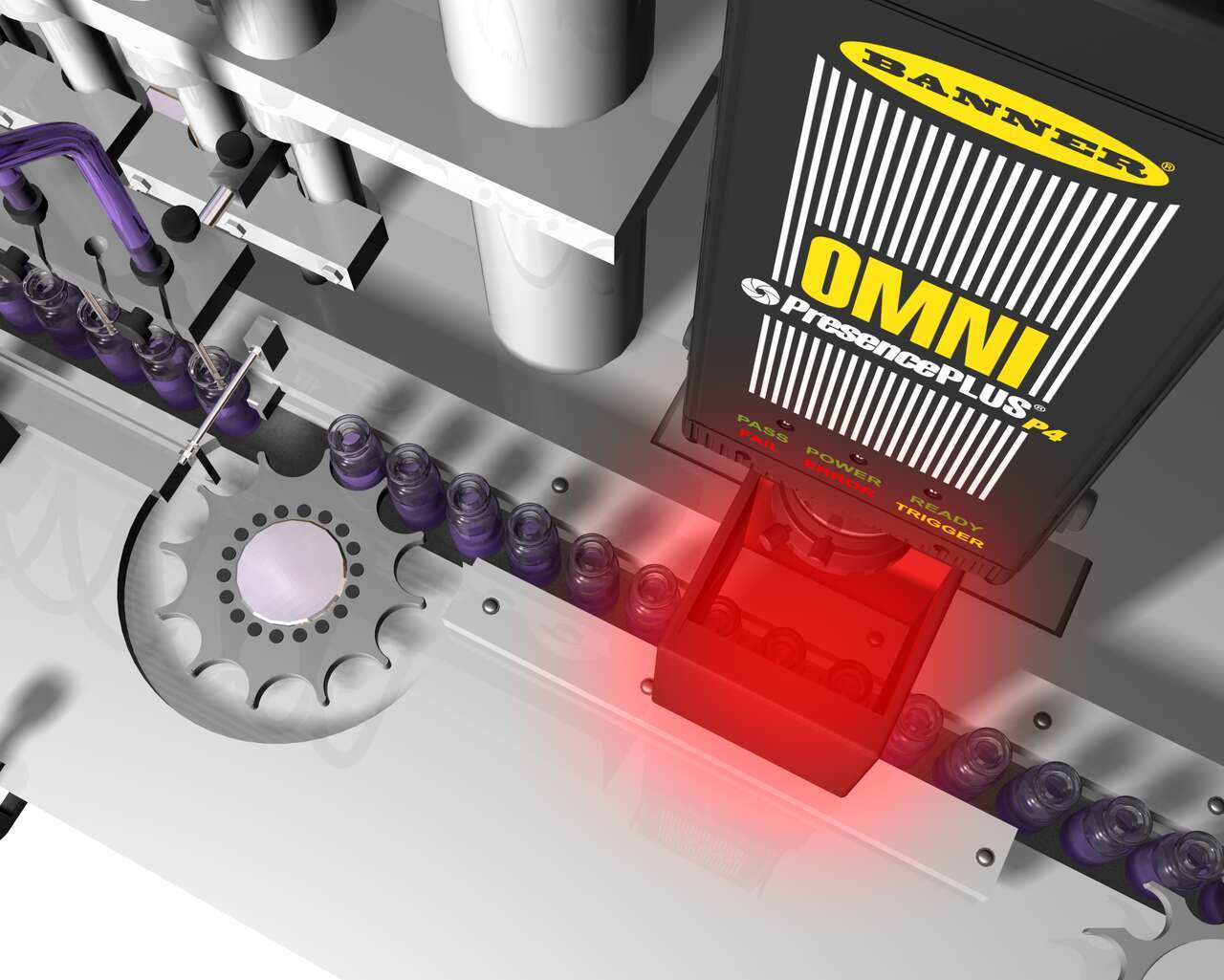

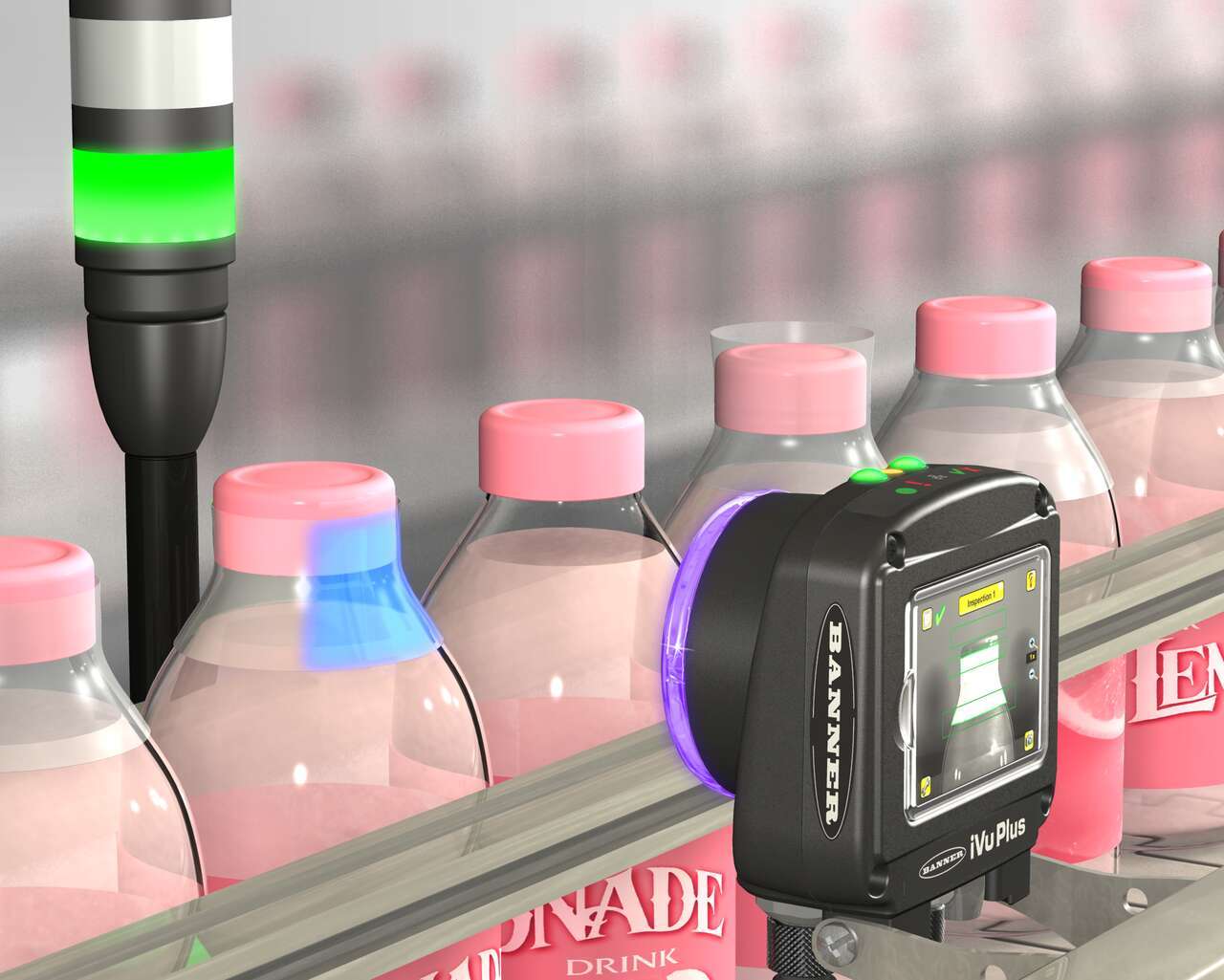

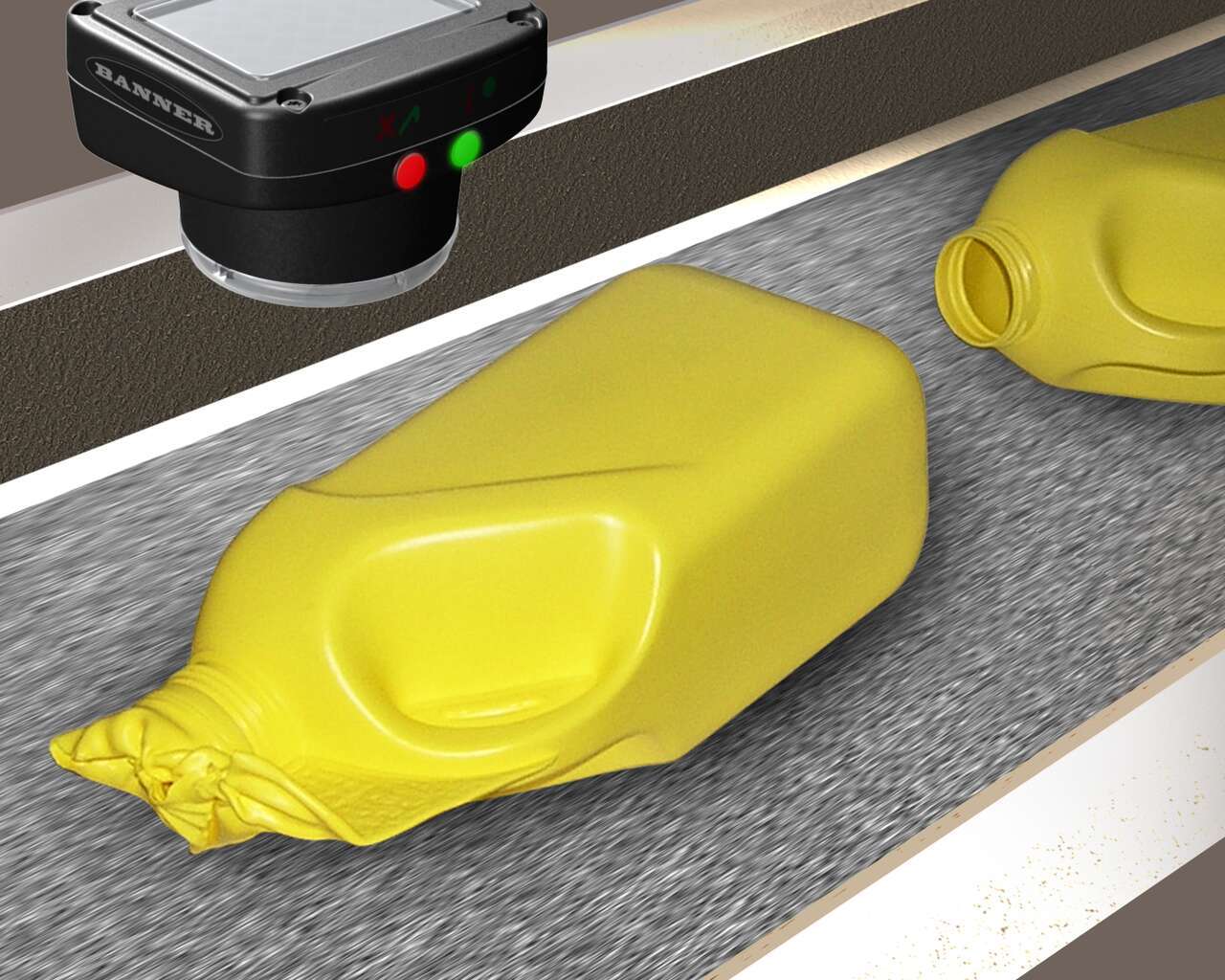

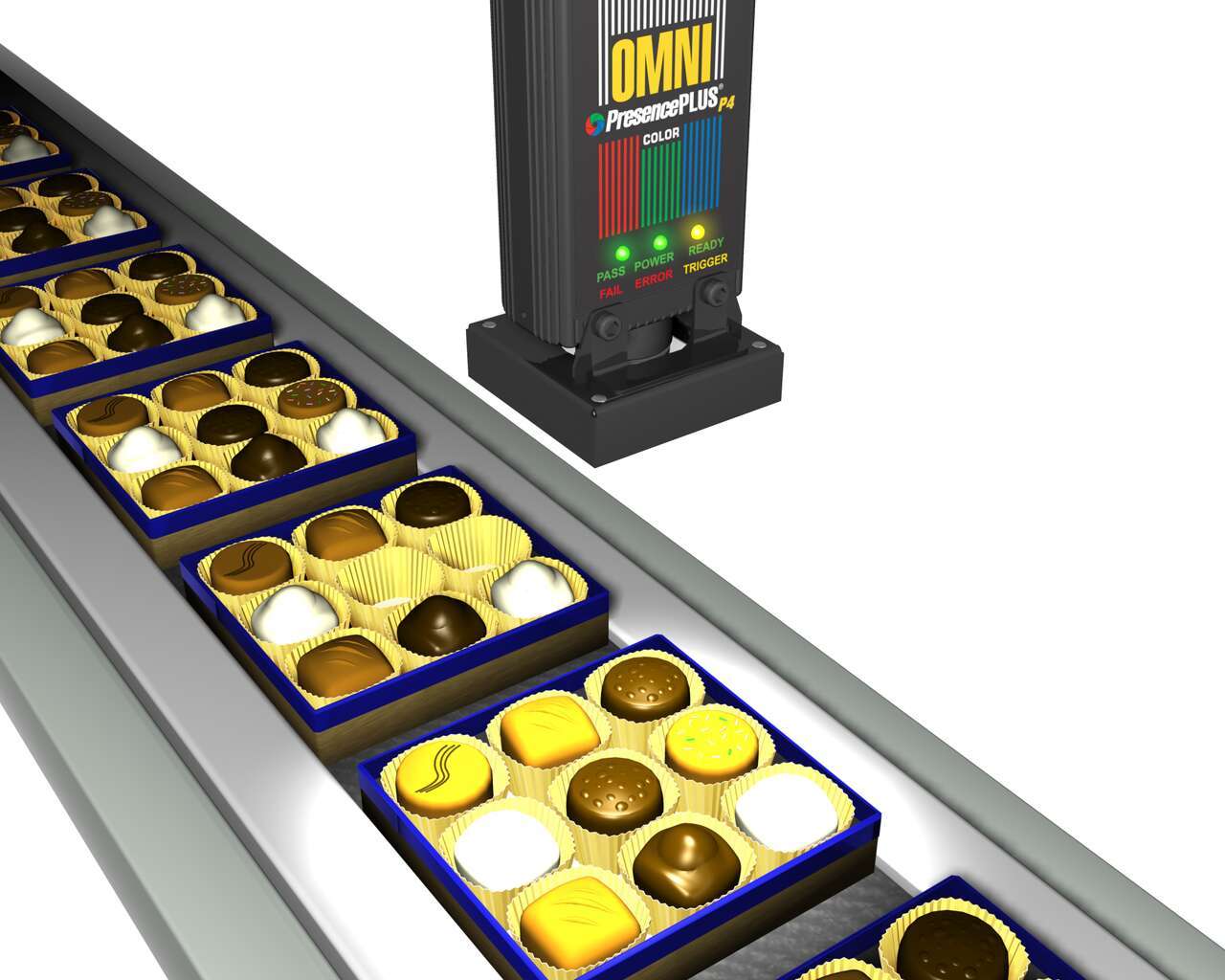

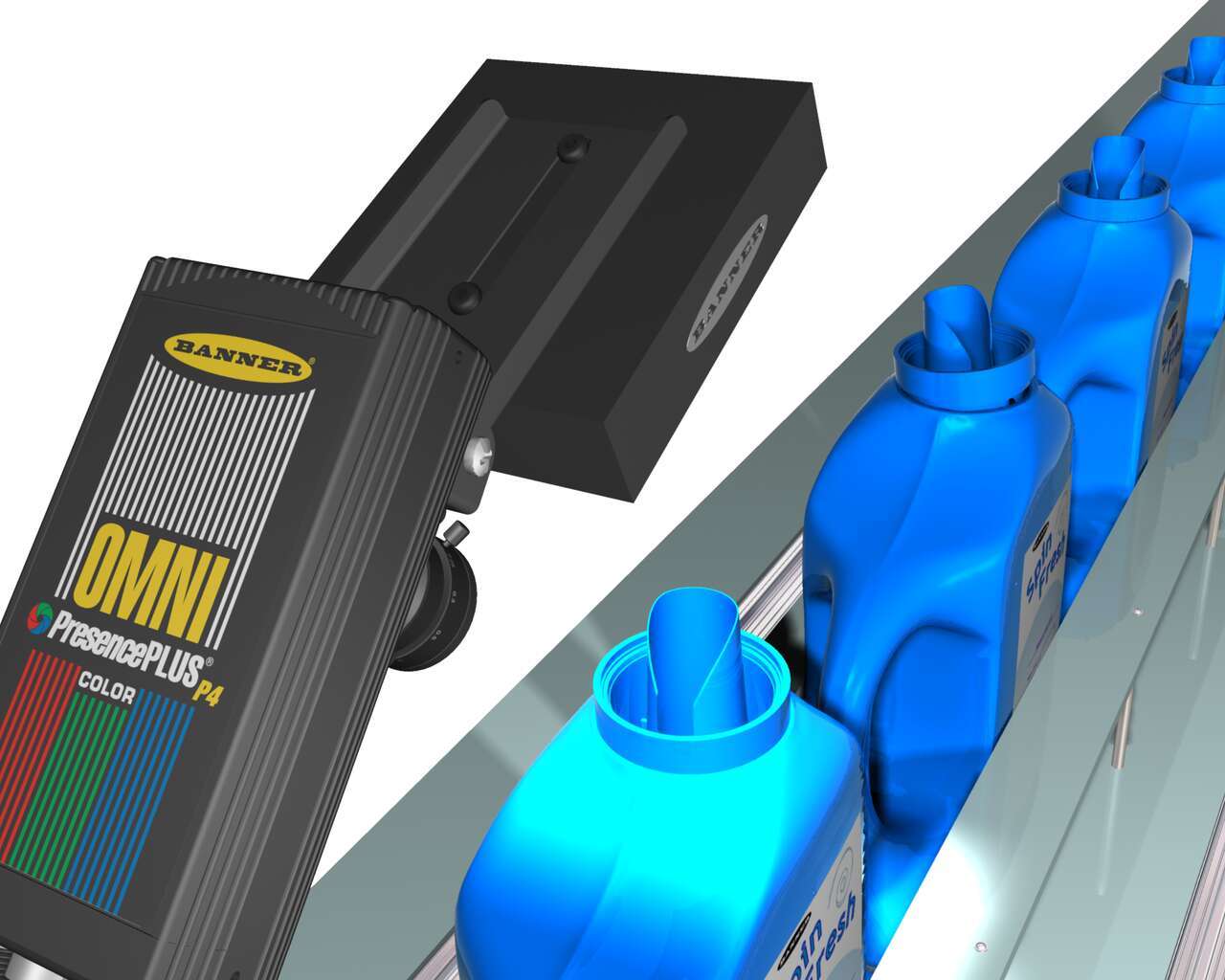

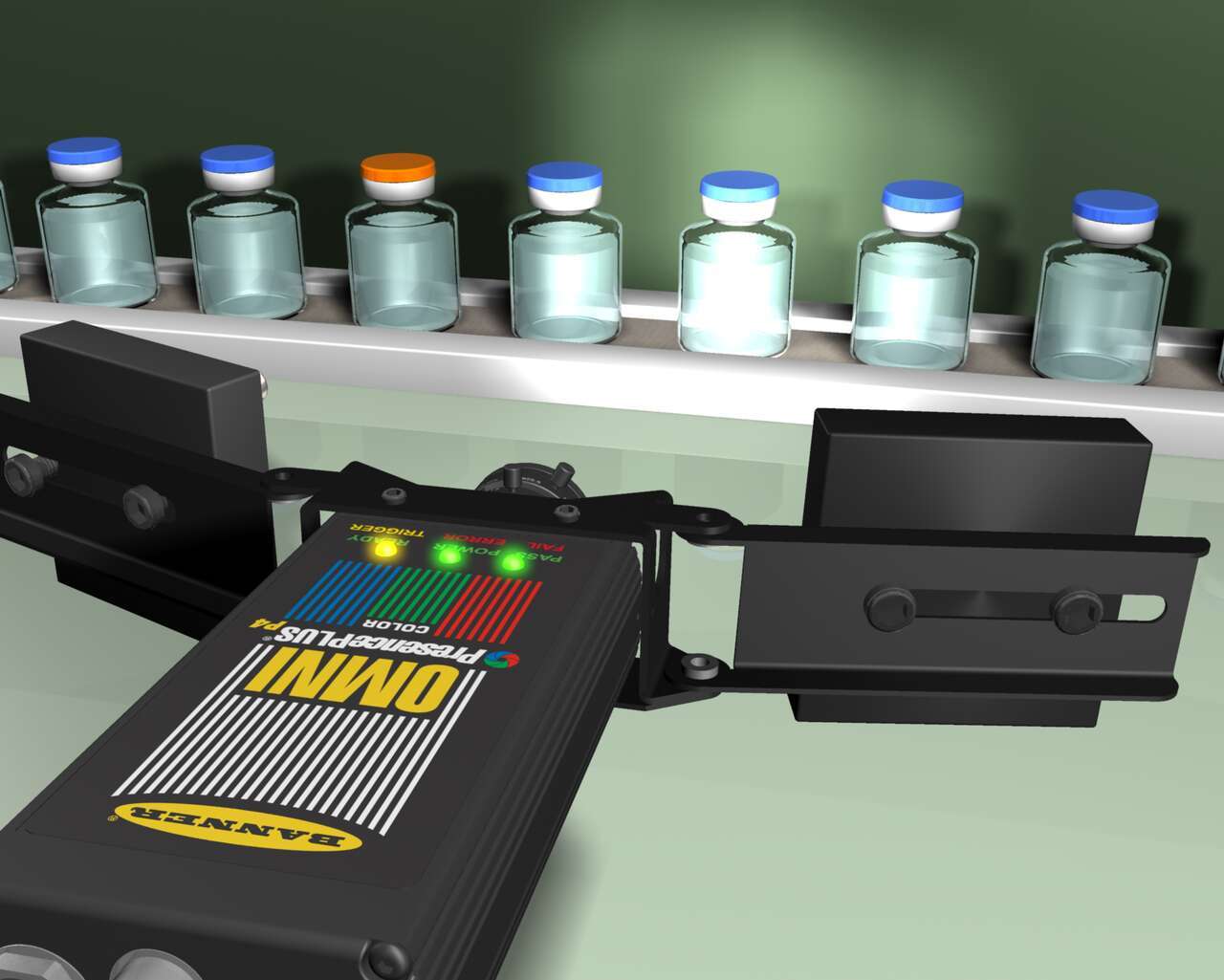

Defects and errors in parts and components can negatively impact downstream processes, production efficiency, and product quality. Consistent, reliable inspection of parts and components can help manufacturers identify potential issues early on in the manufacturing process, minimizing lost product and production time.

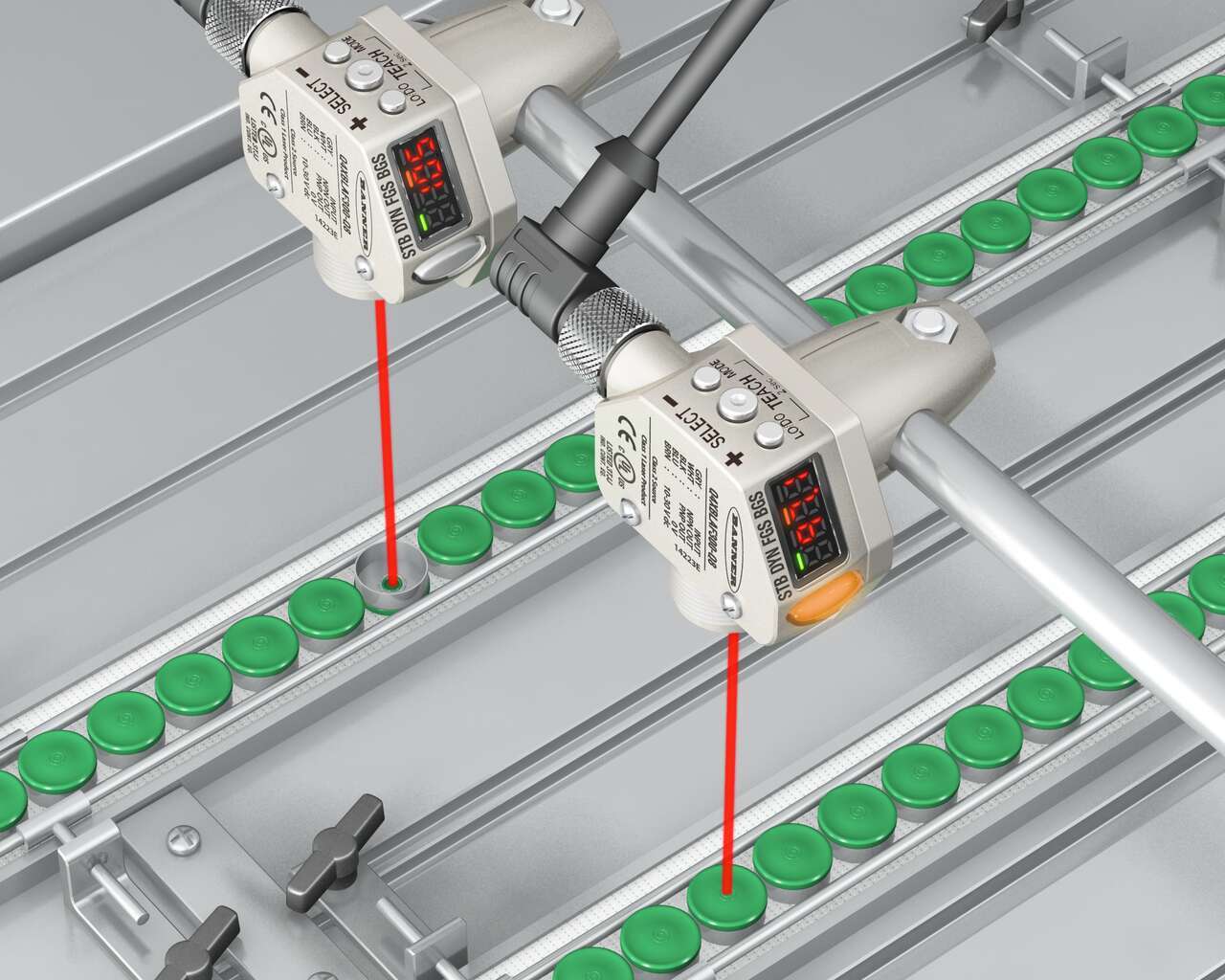

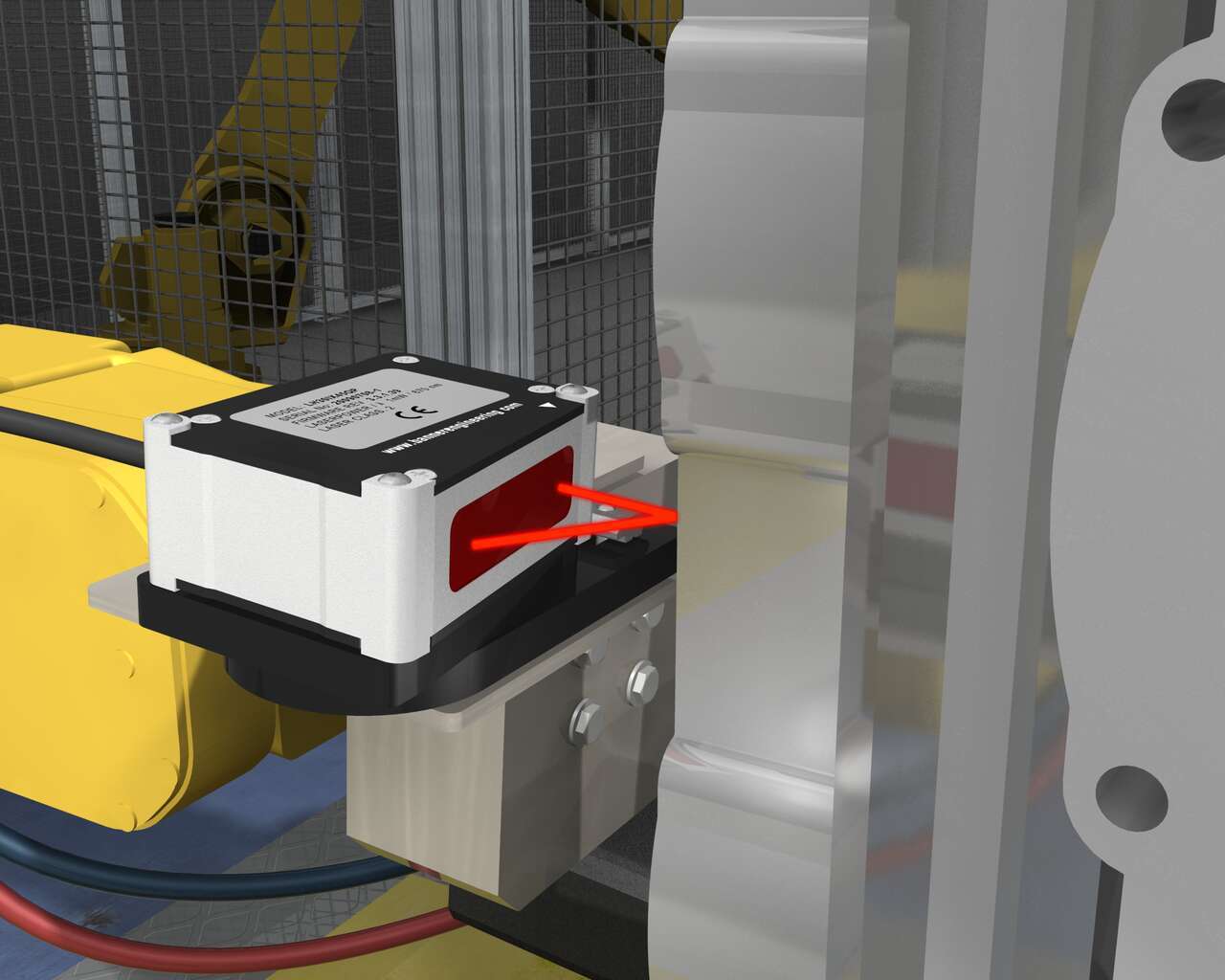

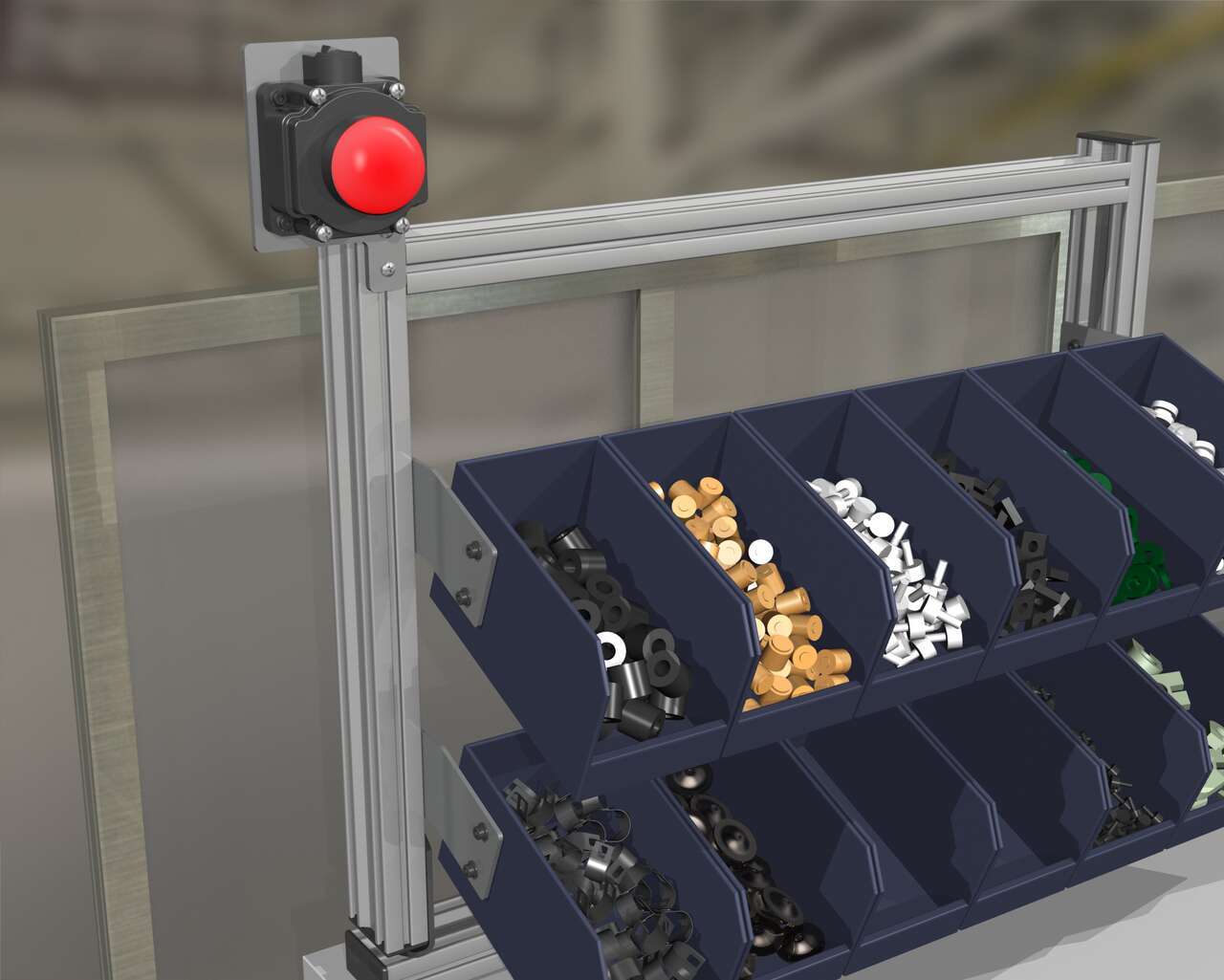

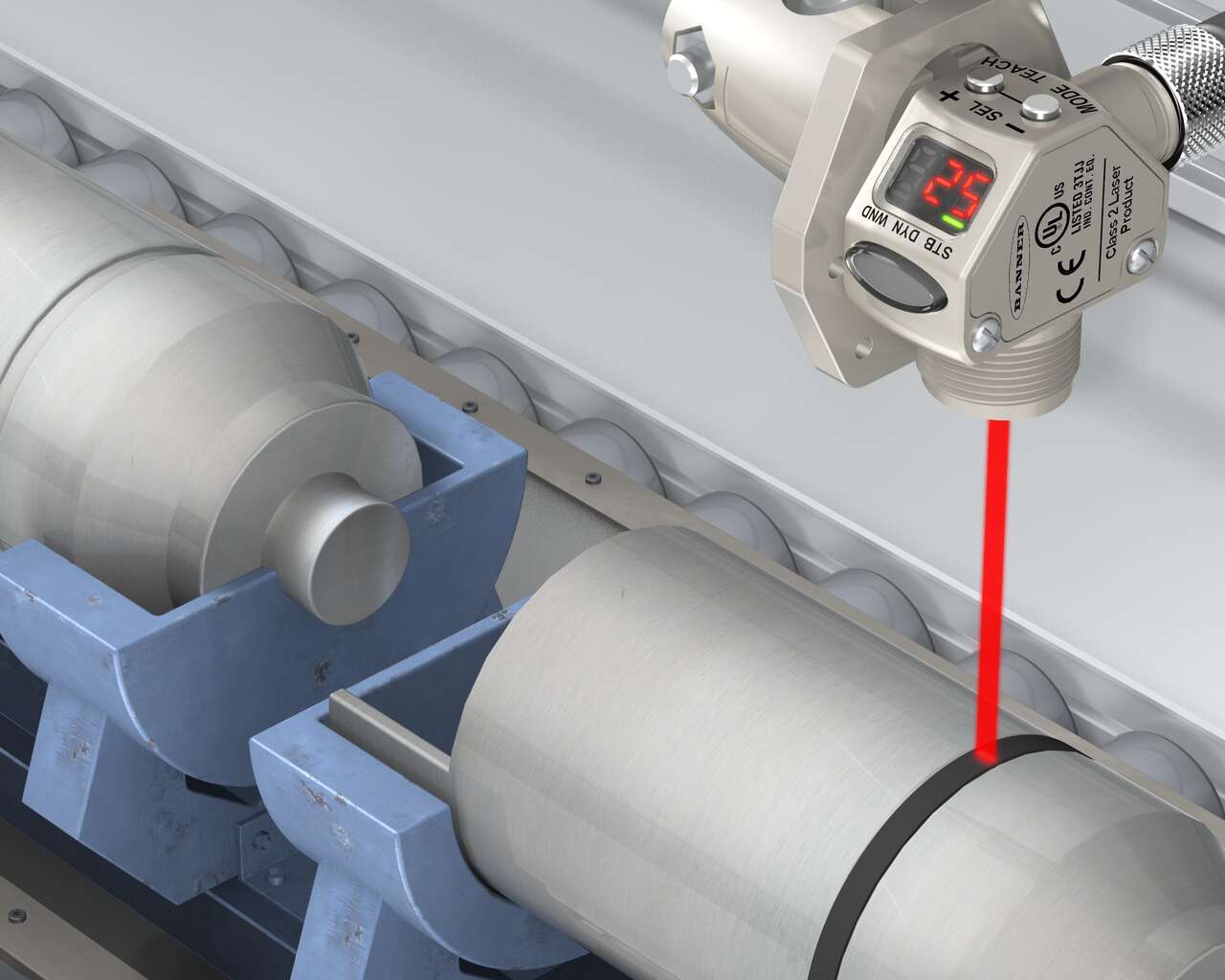

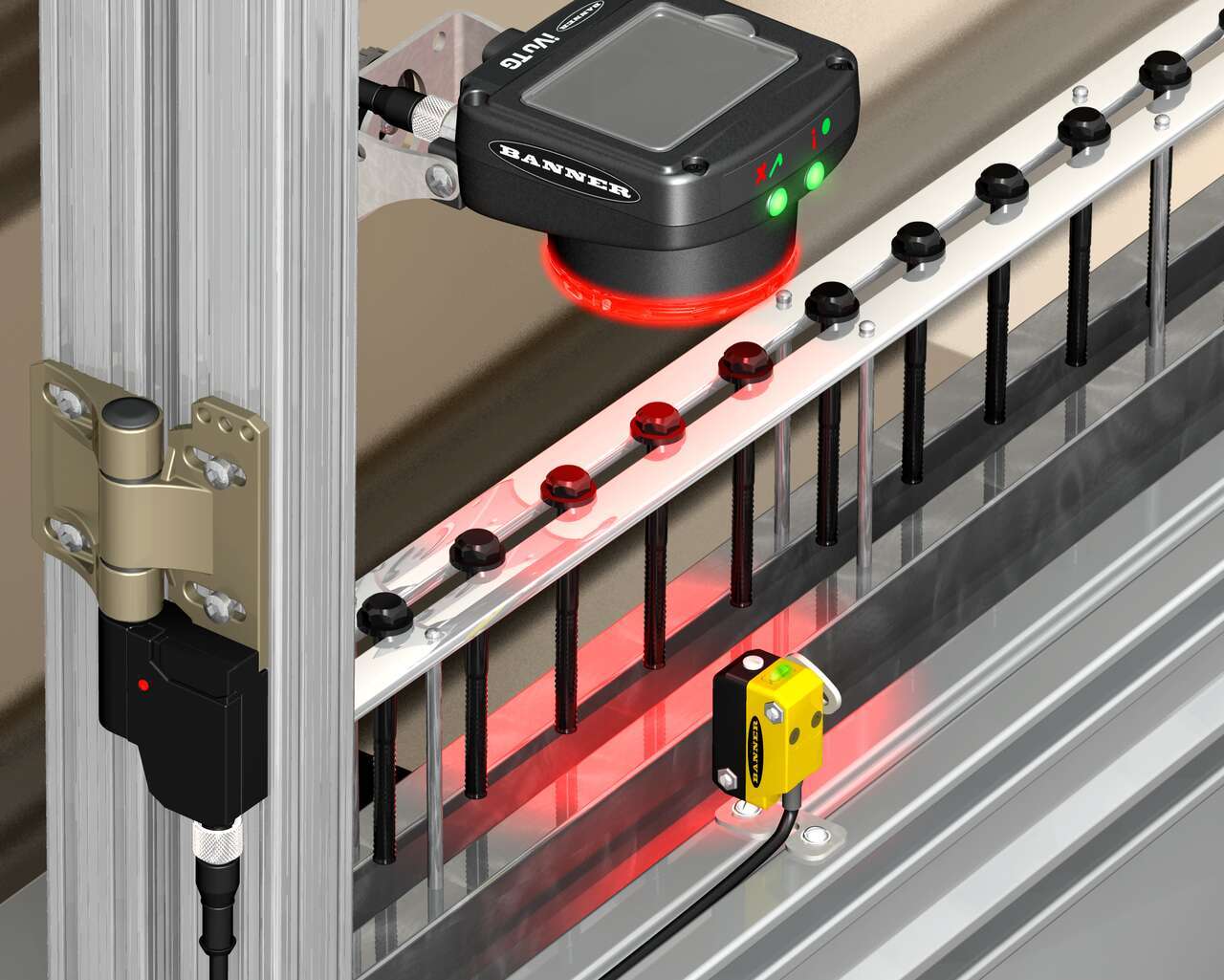

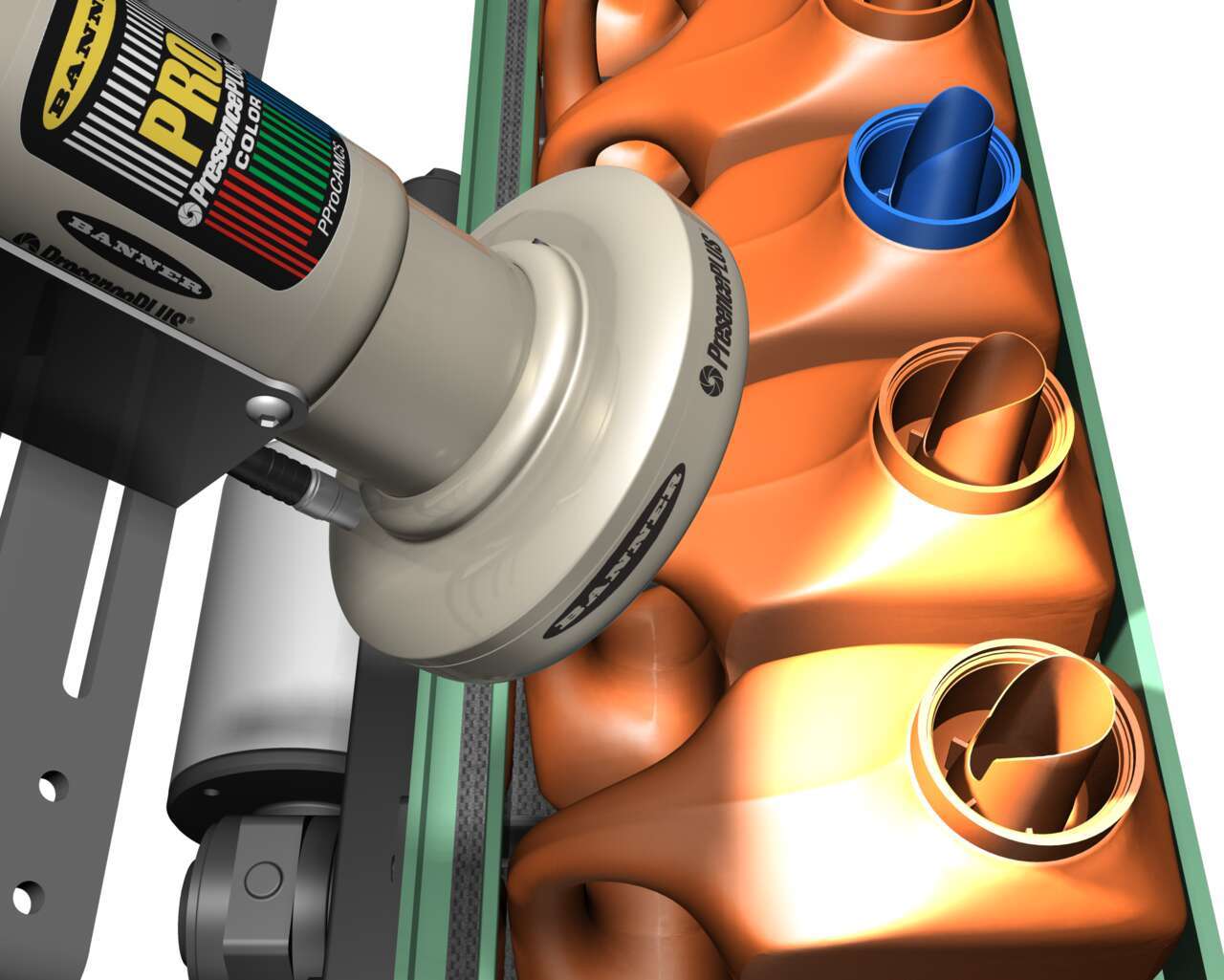

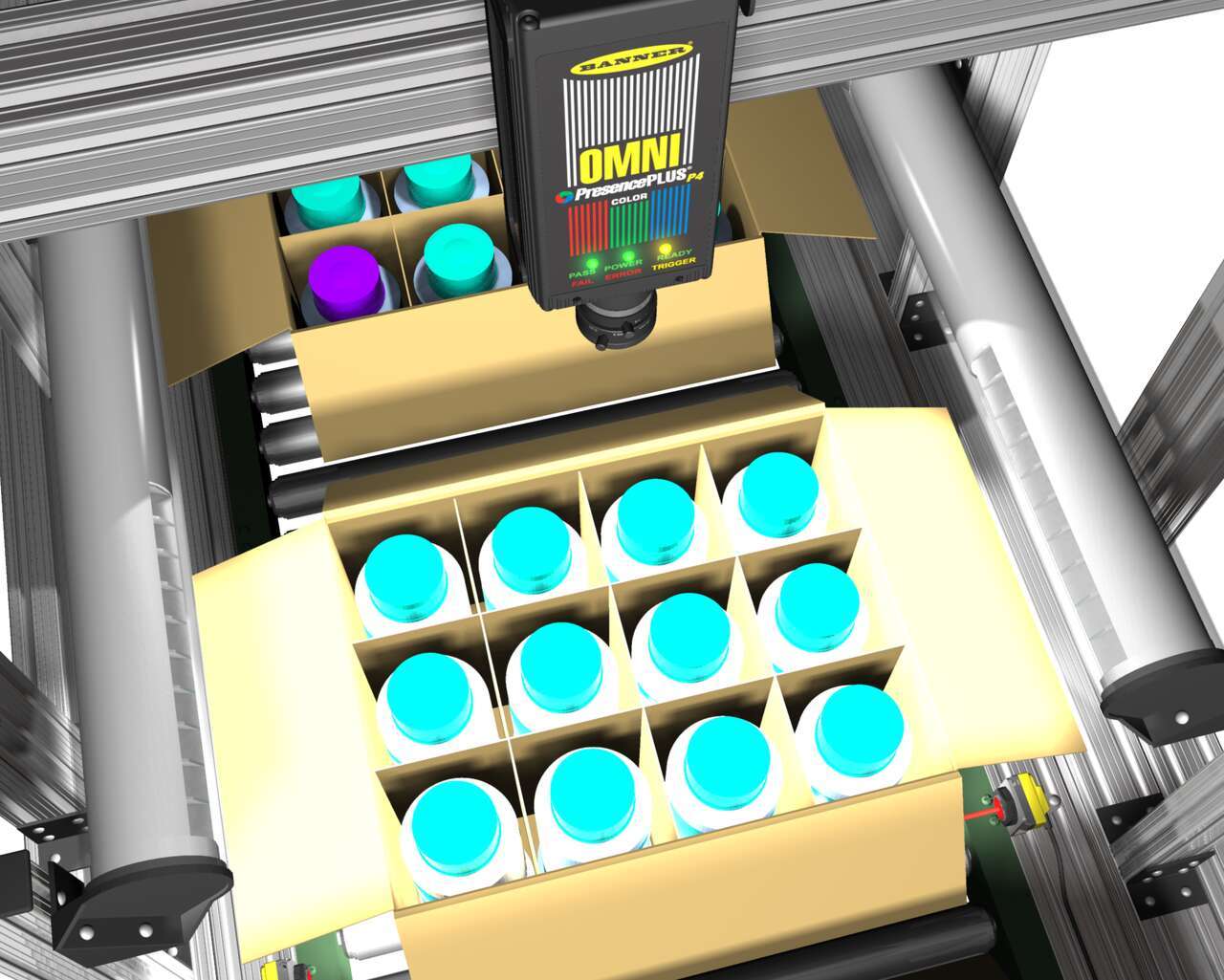

Banner’s expertise in sensing, vision, pick-to-light, and industrial illumination technologies allows us to offer optimal solutions to detect defects, measure components, monitor tolerances, verify product attributes, and reduce the possibility of mistakes or errors--all while increasing productivity.

-

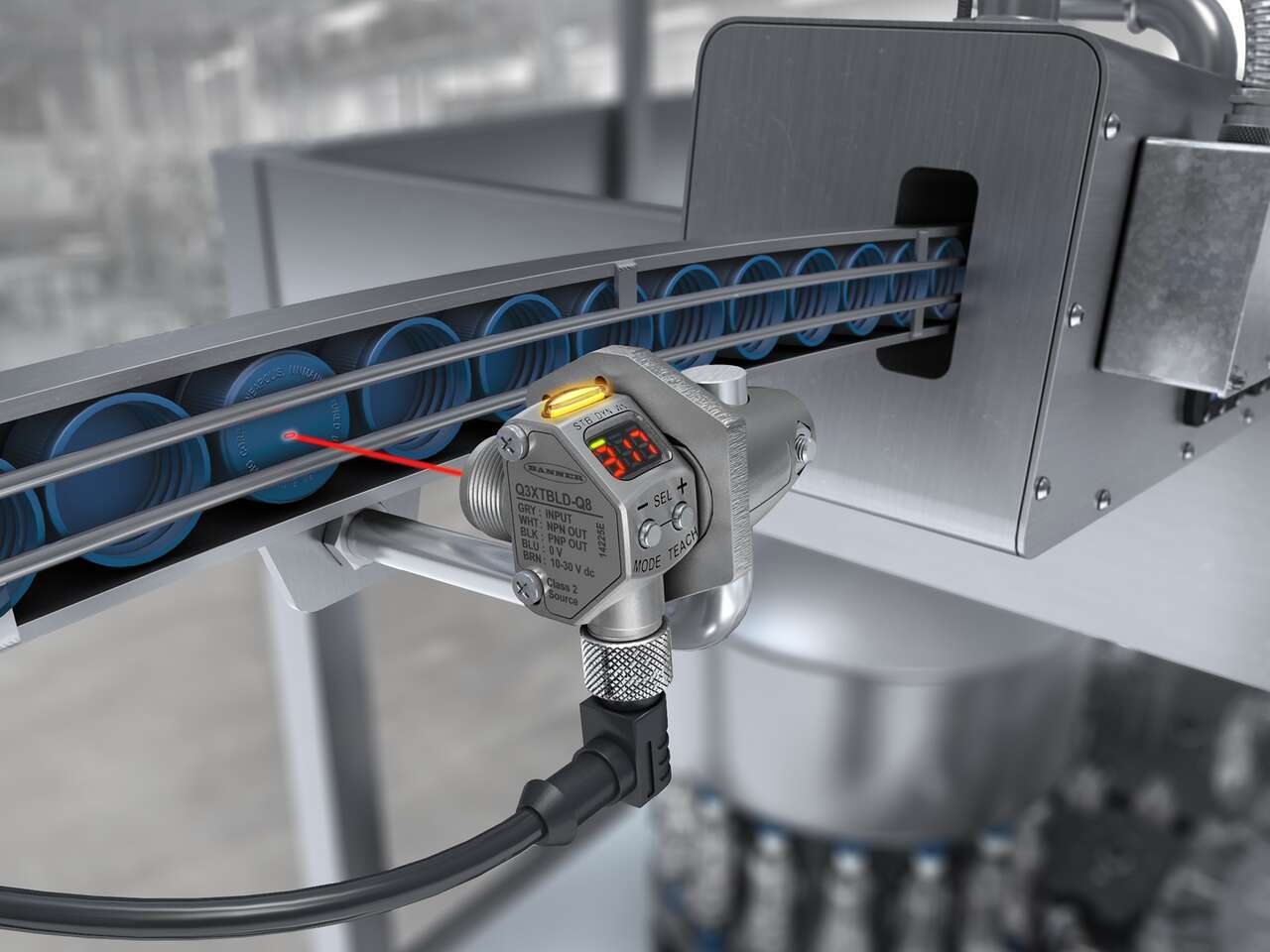

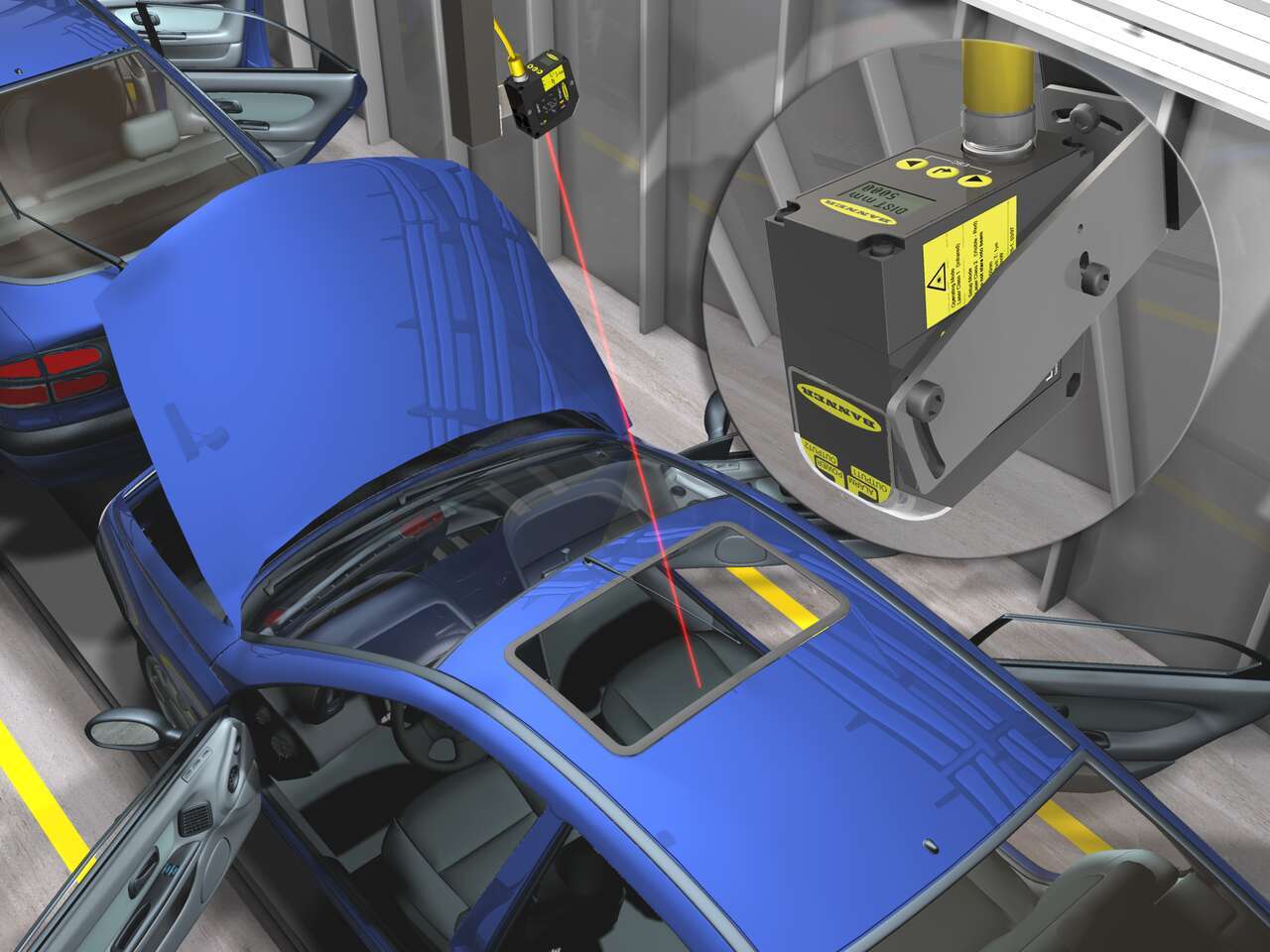

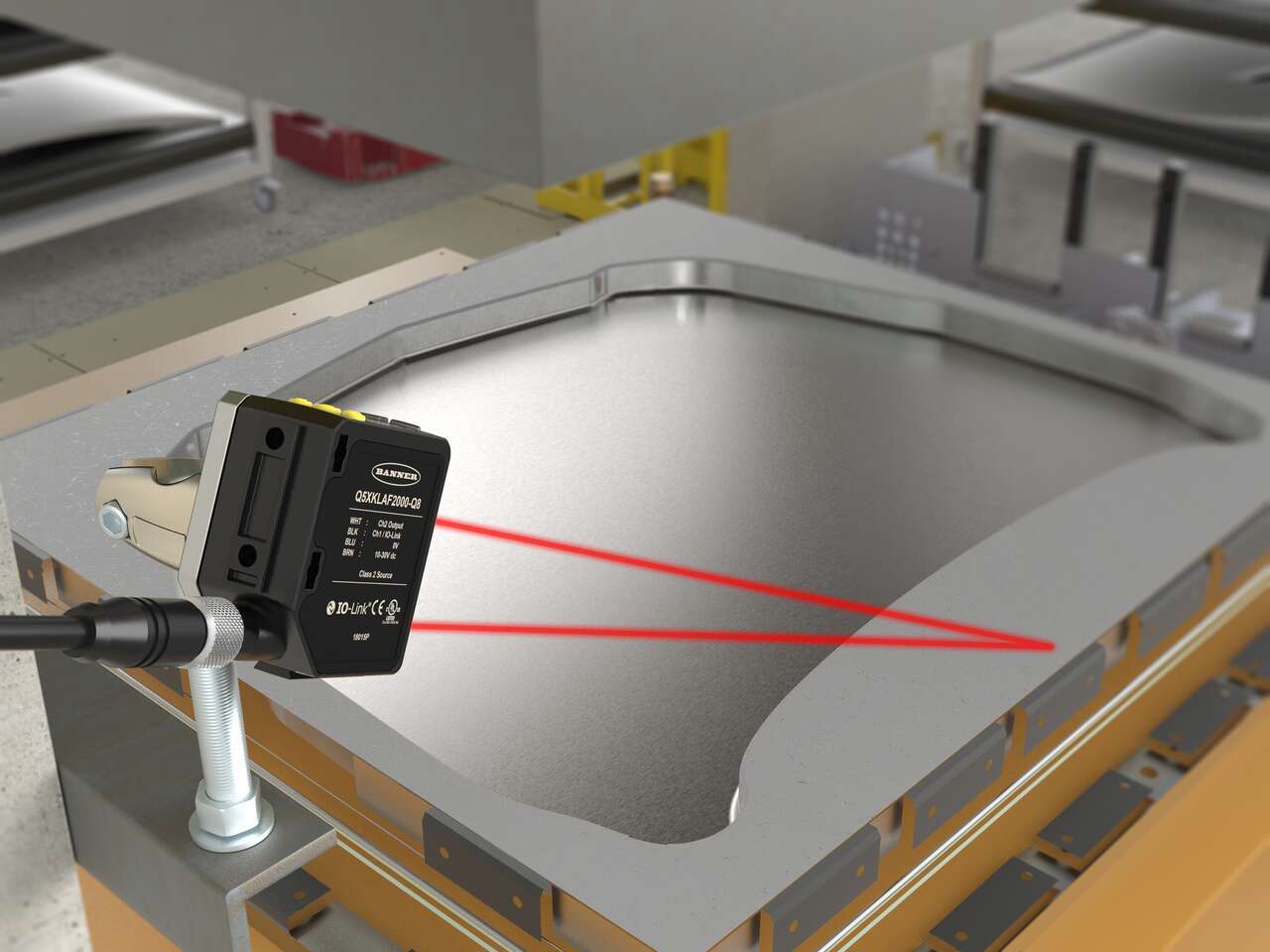

Featured Application | Q5X

Automotive Seat InspectionThe Q5X verifies the presence of dark components on a dark background--as well as vehicle seats and components of varying colors.