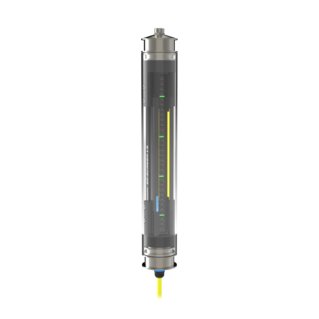

Banner Engineering Cascading Safety Light Curtains - Faster Cascade Means a Smaller Safety Footprint

Learn how Banner Engineering's light curtains' cascade signals outpace the competition, and how that translates to savings in the factory.

To learn more, visit bannerengineering.com.

Transcript

When utilizing more than one safety light curtain, directly connecting to the safety controller provides the guaranteed fastest response times.

But sometimes you might want to connect the light curtains in a cascade configuration, which reduces the amount of wiring and connections at the controller.

Typically the tradeoff with a cascade is each additional curtain adds its own detection delay, and as a result, safety signals can take much longer to get to the controller.

But Banner Engineering’s Light Curtains are built differently.

Banner Light curtains deliver cascade signals up to three times faster than competing products. This is a result of our unique design that only adds as little as two milliseconds for each additional light curtain in a cascaded chain.

The faster response time means your machines require less safety distance between the light curtain and hazard.

So, a machine hazard being safeguarded by Banner Light curtains can have a smaller footprint than the same machine utilizing non-Banner light curtains.

This can translate to a more efficient production environment where the same machines use less factory space, or a scenario where more machines can fit into the same factory space for greater productivity.

What could you do with a smaller equipment footprint?

Speak to a safety expert today and learn if Banner Light curtains could reduce your machine footprint, available at BannerEngineering.com.