Reading DPM Codes on Automotive Components

2D codes etched into automotive components are verified at multiple points during vehicle assembly. The codes are small and complex and can be hard to distinguish from the material they are etched into. Read on to learn how the ABR 7000 barcode reader reliably decodes low-contrast DPM codes.

To ensure that vehicle components can easily be traced throughout their entire life cycle, Data Matrix and other 2D codes are permanently etched into the surface of each component. The codes are small, complex, and dense with information specific to the component. Contrast levels between the codes and the material they have been etched into are low and scratches, surface imperfections, and reflectivity can make the codes difficult to read.

To ensure that each component is genuine original and matches the build order, the code must be verified prior to being installed in a vehicle. If a code cannot be verified, the component cannot be used in the vehicle and must be removed from the line.

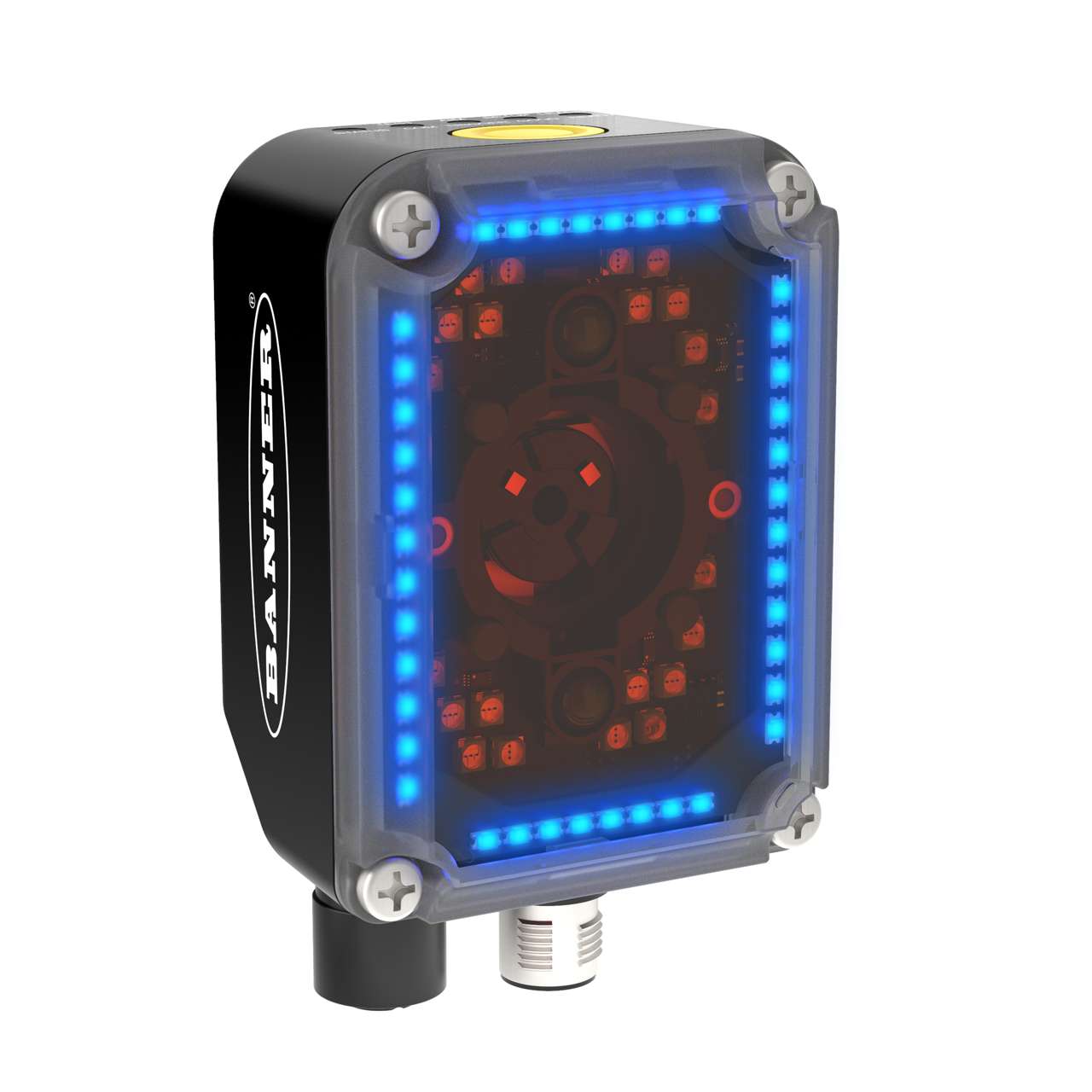

Deployed along the assembly line, an ABR 7000 barcode reader with multicolored LED lights integrated into the device verifies the code on each component entering the inspection area. The ABR 7000 combines superior decoding capabilities with a high-resolution imager and is housed in a compact, IP67-rated metal enclosure.

Using Barcode Manager software, the ABR 7000 can be configured for bright-field or dark-field illumination. Dark-field illumination is better suited for applications like this where the DPM code has been laser etched onto a reflective surface. This lighting configuration utilizes the blue LED lights built into the barcode reader to make the code appear much darker than the surrounding area.

The enhanced contrast between the code and the surface of the component allows the ABR 7000 to capture a detailed image of the inspection area with every aspect of the datamatrix code well defined. The information contained in the code is then verified and sent over an Ethernet connection to the factory management system which logs the data.

Superior Decoding of Challenging Barcodes

ABR 7000 barcode readers utilize advanced algorithms to decode a full library of 1D and 2D barcodes. Models with a 1.3 MP (1280 x 1024 pixels) imager reliably capture fine details on small, complex, and challenging barcodes. Models with a 2 MP (1600 x 1200 pixels) imager offer increased resolution to read smaller codes over a larger target area and at greater distances.

Integrated Multicolor Lighting for DPM Applications

The ABR 7000 is available in models featuring integrated red or multicolor LED lights. Multicolor models can be configured for bright field or dark field illumination. Bright-field lighting is best for illuminating DPM codes on flat surfaces with machining flaws while dark-field illumination is best improving contrast in applications where the code has been laser etched or dot peened into a flat, reflective surface.

Easy Installation in Industrial Environments

The ABR 7000 is protected from hazards common to industrial environments by a rugged, IP67-rated metal housing. It has an all-in-one design that combines imager, lens, and LED lighting in one compact device and features a rotating connector that simplifies installation in difficult and space constrained deployments.

Intuitive Software with Advanced Capabilities

Connect, configure, and monitor multiple ABR Series devices using Barcode Manager. This free and easy-to-use software features flowchart programming that makes it easy to setup inspections and access advanced capabilities.