Traceability in Pharmaceutical Supply Chain

Ensure Safety and Compliance with Regulations

Pharmaceutical traceability is required to eliminate counterfeits, ensure patient safety, and comply with regulations.

According to GS1, the global traceability standard for healthcare, "Traceability in healthcare enables you to see the movement of prescription drugs or medical devices across the supply chain. You can trace back to identify the history of the transfers and locations of a product, from the point of manufacture onwards. And you can track forwards to see the intended route of the product towards to the point of care."

Know the What, When, Where, and Why

In the healthcare industry, counterfeit or defective product can have significant consequences on patient health. Because of this, pharmaceutical manufacturers must adhere to strict regulations to ensure that their products can always be traced back to their source and that the Chain of Custody (CoC) and Chain of Ownership (CoO) for products are reliably documented. In addition, manufacturers must be able to quickly and completely recall any defective products to ensure patient safety.

To accomplish these goals, a reliable barcode reading solution must be implemented at every stage of the process. Barcode readers capture valuable data which can be used, when needed, to determine four dimensions of traceability outlined by GS1:

- What products are impacted?

- When did this time-stamped event occur?

- Where was the product. Where is it now?

- Why was this observed, which process step?

Ensure Product Quality and Complete Accuracy

- In the pharmaceutical industry, barcodes are often printed with clear ink that can be challenging to detect on labels due to minimal contrast.

- It is vital that each label has a barcode to ensure the highest quality product and complete accuracy.

- An iVu BCR barcode reader with ultraviolet (UV) ring light is an ideal solution for detecting bar codes in a low contrast situation.

- The iVu is coupled with UV illumination for an all-in-one solution that improves contrast on clear labels, so barcodes are easily and accurately detected for reliable traceability.

Verify Correct Product and Documentation

- Once the product itself has been verified for accuracy and quality, medicine bottles must be packaged into the appropriate boxes.

- Also, box inserts (that include user instructions and warnings) need to be verified and identified before sealing the package to ensure accurate documentation is delivered to the customer.

- To quickly and efficiently perform this inspection, the data matrix code on the documentation is read and verified before the final packaging process.

- The iVu BCR barcode reader verifies that the Data Matrix code on the insert matches the product on the packaging line. In doing so, the barcode reader also gathers valuable data that can be used to identify and isolate any issues that may arise.

Reliable Code Reading in Tight Spaces

- Another common challenge in the pharmaceutical industry is that products, such as pill bottles and vials, are quite small.

- Because of this, the codes affixed to the products are often small, wrapped around a curved surface, and challenging to read.

- In addition, there is often limited space to mount a code-reading device.

- The ABR 3000 compact barcode readers from Banner reliably read difficult codes in tight spaces and reach GS1 standards for the pharmaceutical industry.

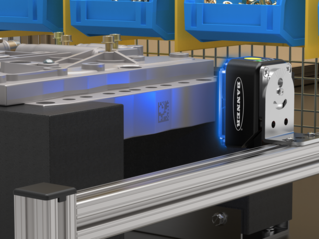

Compact Imager-Based Barcode Reader

ABR 3000 barcode readers offer superior decoding capability in a compact form factor, multiple resolutions, and a wide range of lens options.

- Powerful decoding capability to read even difficult 1D and 2D codes

- ABR 3000 is ideal for tight spaces and close-range code reading

- Compact metal housing for industrial environments

- Quick configuration with on-board push buttons or a PC using Barcode Manager, Banner’s free operating software

- Integrated LED lighting and easy focus adjustment in one package for maximum application flexibility

- Factory communication options include Ethernet or USB for integration on the manufacturing floor

- Embedded web server interface for monitoring images and statistics over any network

Imager-Based Barcode Reader

iVu BCR Series barcode readers combine powerful decoding capabilities with ease-of-use to solve challenging traceability applications. These versatile barcode readers are available with a range of lens, lighting, and user interface options.

- Reads a broad range of 1D and 2D barcodes, including damaged, distorted, and other difficult-to-read codes

- Capable of reading multiple barcodes in any orientation in a single inspection

- Setup, manage, and monitor inspections using an integrated touch screen, remote touch screen or PC interface

- Ethernet and serial communication protocols simplify device integration and enable IIoT data collection

- Rugged, IP67-rated housing ideal for tight spaces and industrial environments

- Numerous integrated lighting options simplify installation and optimize contrast

- Interchangeable lenses, including a wide range of standard and C-Mount options to meet the needs of any application

ABR 7000

Powerful Imager-Based Barcode Reader

ABR 7000 barcode readers offer superior decoding capability and are in multiple resolutions and a wide range of lens options.

- ABR 7000 barcode readers provide advanced features including extended reading distance and field-of-view, advanced lighting, a variety of focal lengths (including autofocus) and the ability to link multiple readers together.

- Powerful decoding capability to read even difficult 1D and 2D codes, including DPM and low contrast codes

- Quick configuration with on-board push buttons or a PC using Barcode Manager, Banner’s free operating software

- Integrated LED lighting and easy focus adjustment in one package for maximum application flexibility

- Versatile lens options are available to simplify setup and configuration, including a software adjustable autofocus which easily adapts to changes in reading distance

- Factory communication options include Ethernet and serial for integration on the manufacturing floor

- Embedded web server interface for monitoring images and statistics over any network