Dynamic Maintenance Indication on a Beverage Line

Clear status indication can be challenging for machines with a wide range of operating conditions; however, unclear indication can lead to wasted time and lost productivity. Read below to learn how the TL50 Pro programmable tower light uses both traditional and advanced indication capabilities to help focus workers’ attention where it is most needed to maximize efficiency and uptime.

The beverage industry is a highly automated environment with a variety of machines throughout the production line. Clear machine status indication helps maximize uptime and increase throughput by helping machine operators quickly identify and resolve critical conditions. In addition, clear communication of non-critical states is just as important to help workers focus their time and attention where it is needed most.

Traditional tower lights typically feature 3-5 colors with each equating to one condition or type of condition. This limits the number of statuses that can be represented. For example, a typical tower light might display when the machine is running, not running, and error statuses like a jam in the line.

However, machines can also be in transitional states—like changeover, maintenance, or warmup—that traditional tower lights do not capture. When a machine is in one of these states, a typical tower light might display a red light, indicating that the machine is not running. From a distance, supervisors may see that the machine is not currently running. However, they would be unable to quickly identify the cause without walking over to the machine, resulting in time wasted checking a machine that does not require attention. A solution is needed that offers advanced functionality to display more dynamic statuses clearly across the factory floor.

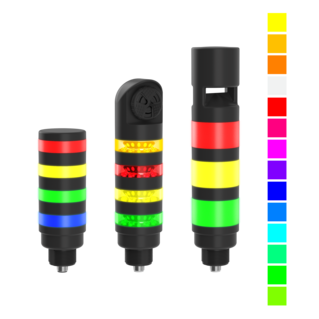

Banner Engineering’s TL50 Pro tower lights offer the same segment control as traditional tower lights, but also feature advanced options that add clarity and nuance to the visual language of machines. Using Banner’s intuitive Pro Editor software and a single input, the TL50 Pro can be programmed to display action mode animations that utilize the entire tower light, providing more insight into machine status at a glance.

In this application, the tower light in action mode displays blue LEDs that bounce up and down the entire length of the tower light. The bright blue animation clearly informs operators that maintenance procedures are in progress, allowing them to focus on other productive activities while waiting. In addition, supervisors can easily interpret machine status from a distance, reducing time spent checking on machines unnecessarily.

Advanced Functionality without Requiring IO-Link

With the Pro Editor software, users can easily customize the TL50 Pro tower light with a wide variety of predefined color and animation options without requiring IO-Link. Pro Editor models are discretely controlled and ideal for users who do not have IO-Link, but who want more control and customization than a standard indicator.

Give Your Machines a Voice

From classic segment control to advanced status indication, TL50 Pro tower lights enable a wide range of possibilities. The variety of colors and animations add nuance to the visual language of your machines and provide more insight at a glance. In addition to providing traditional status information with each segment, the whole TL50 Pro tower light can be used to indicate dynamic statuses.