Assembly Timer Indication at Automotive Assembly Station

In automotive manufacturing, maximizing efficiency is crucial in order to meet production goals. Delays at assembly stations can hold up processes later down the line, leading to costly wasted time and missed production targets. Continue reading to learn how the TL50 Pro programmable tower light helps assemblers meet expected cycle times and support overall takt time requirements.

Automotive lines have many different assembly stations, and delays at any stage can significantly impact overall production goals. Automotive manufacturers often use takt time, the time between the start of production of one unit to the start of the next, to measure efficiency and ensure that goals are met. Tower lights at each assembly station can be used to help assemblers monitor their pace and adjust accordingly, ensuring each step of the process remains on target and supports overall takt time requirements.

TL50 Pro tower lights, configured in timer mode with Banner’s free Pro Editor software, provide assemblers with easy-to-interpret visual feedback to help workers keep track of and adjust their pace as needed—and warn them when time is running out to complete a cycle.

Pro Editor models of TL50 Pro tower lights include an integrated timer and can be configured to visually display a countdown of cycle time remaining. In this example, a photoelectric sensor detects when components are ready and begins a timer that illuminates all segments of a 4-segment tower light in green. As time elapses, fewer segments are lit, and the color changes from green to yellow. With 25% time remaining, only the bottom segment remains lit and changes from yellow to red to warn assemblers that time is running out. The worker must complete the cycle before the timer is finished.

The TL50 Pro tower light is easy to configure and deploy quickly with the Pro Editor software. In addition, there is no need for an external PLC or Ethernet connection. The compact tower light with bright LEDs creates a highly visible solution that takes up minimal space in the station, allowing assemblers to easily monitor and manage their time without interrupting their workflow.

Advanced Functionality without Requiring IO-Link

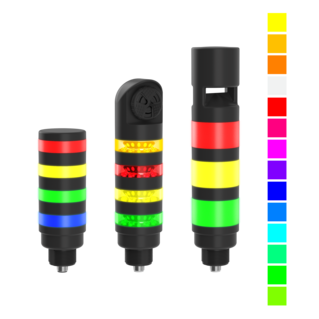

With the Pro Editor software, users can easily customize the TL50 Pro tower light with a wide variety of predefined color and animation options without requiring IO-Link. Pro Editor models are discretely controlled and ideal for users who do not have IO-Link, but who want more control and customization than a standard indicator.

Give Your Machines a Voice

From classic segment control to advanced status indication, TL50 Pro tower lights enable a wide range of possibilities. The variety of colors and animations add nuance to the visual language of your machines and provide more insight at a glance. In addition to providing traditional status information with each segment, the whole TL50 Pro tower light can be used to indicate dynamic statuses.