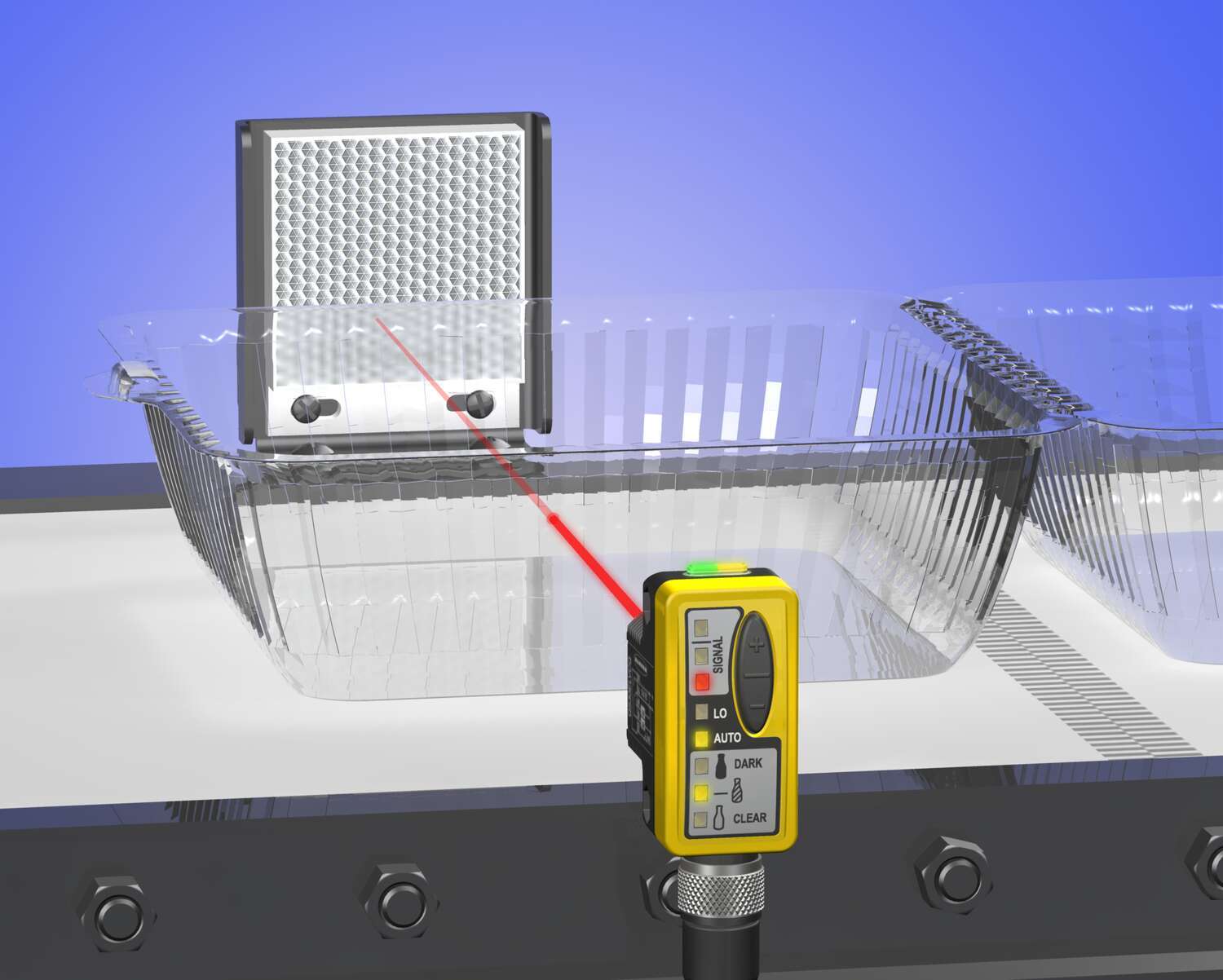

Counting Transparent Plastic Containers on a Conveyor

Application: Counting plastic containers

Challenges: Containers are clear and have various ridges

Solution: Banner Engineering's QS30ELVC retroreflective sensor

Benefits: The QS30ELVC detects a clear object with only 8% of reflected light

Plastic container detection is challenging because containers are clear and can have ridges, which may attenuate light differently and can be difficult to detect accurately. In order to count these containers as they move down the conveyor, it is important to have a dynamic sensor that can sense clear or transparent items and do so quickly and accurately.

Description

The QS30ELVC retroreflective sensor is the ideal solution for detection of clear targets because it has an 8% threshold for clear object detection, which allows a clear object to be detected as long as it attenuates at least 8% of the light passing through it. The sensor has a minimum range of 100 mm, which is great for small conveyors and limited spaces, with a maximum range of 2 m.

The configuration and setup of Banner’s QS30ELVC is quick and easy with a TEACH mode that learns the amount of light reflected back as the clear condition with just a simple touch of a button. The sensor has an automatic compensation algorithm that compensates for dust and contamination on the sensor/reflector for consistent and reliable detection that reduces down time. The QS30ELVC also compensates for ambient temperature changes.

The QS30ELVC has a 500 microsecond response time to accurately detect clear containers in high speed counting applications, and the reflector is available in a square or smaller rectangular shape to meet various user needs.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)