Part Color Inspection on a Vehicle Door Panel

Application: Identify and verify vehicle trim colors match the build order

Challenge: Interior trim pieces are interchangeable, but vary in color, making it easy to install the wrong piece. As assembly progresses, correcting errors becomes more difficult.

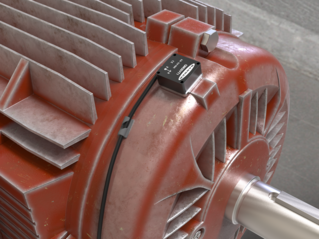

Solution: iVu Series Color Sensor with Integrated Touch Screen

Benefits

- Average Color tool identifies subtle variations in part color

- Interchangeable lenses increase sensor range and resolution

- Touch screen operation with a graphical user interface simplifies device configuration and inspection management

- Ethernet/IP™, Modbus TCP®, and PROFINET® industrial protocols makes it easy to export color values to a PLC

Interchangeable Parts in a Range of Colors

Automotive trim packages can vary with each vehicle on the line. Many interior trim pieces are interchangeable and available in multiple color options. To ensure that the correct trim package has been applied to a vehicle, individual trim pieces must be inspected at each stage of assembly.

Inspecting Part Color to Identify Assembly Errors

Deployed in the interior assembly area, an iVu Color Sensor with a C-mount lens inspects interior trim pieces on each vehicle door panel. The C-mount lens extends the working distance of the sensor, enabling installation away from the operator’s work area without compromising the resolution level necessary for the inspection.

Using the integrated touch screen, the iVu Color is configured to use the Average Color tool, which identifies the RGB or HSI values of the area captured in the region of interest. This information is communicated over an industrial Ethernet connection to a PLC, which compares the reported values against those specified in the vehicle build order. If the reported values are incorrect, assembly staff will be alerted so the error can be corrected before further assembly can occur.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)