Multiproduct Light-Guided Assembly Station

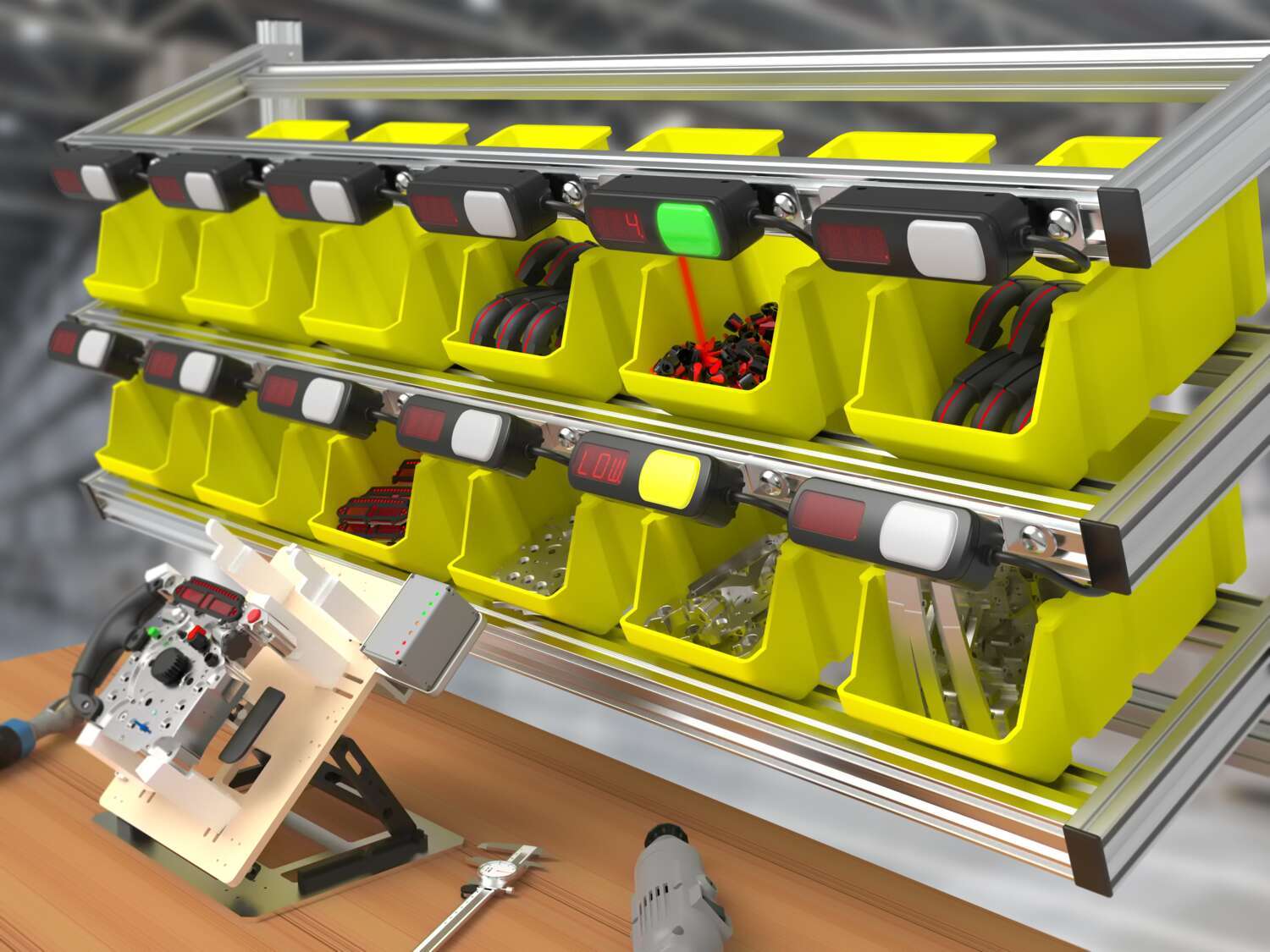

Assembly of multiple parts at one station can be a very effective way to build components for various models, but it also presents many challenges that must be addressed before accurate assembly and high throughput is possible. Continue reading to learn how the versatile PTL110 Series pick-to-light devices can be used for error proofing and guidance during part assembly.

Errors can be very common when parts are manually assembled and there is a demand for a variety of different parts. Similar components and hard-to-follow instructions may lead to human error during production which then slows down the entire process and introduces defects. Using pick-to-light sensors at multiproduct assembly stations lessens the number of inaccuracies, speeds up build time, and makes training simple and easy.

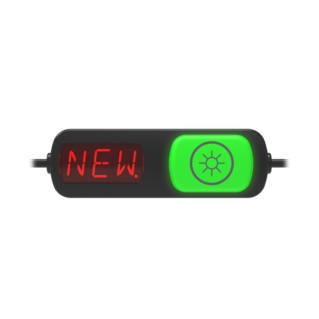

The PTL110 Series is an incredibly versatile and fast pick-to-light device that is a great fit for light-guided assembly applications. Minimizing errors during assembly procedures is crucial for companies to keep production levels high and reduce the amount of downtime. Without proper guidance during pick sequences, an operator can easily grab from the wrong location and install incorrect components. The bright and easy-to-see digital displays on the PTL110 devices, combined with an optical sensor that detects hands as they pick pieces, simplifies the build of parts and ensures a high level of quality assurance at multiproduct assembly work stations.

When a specific part is needed, the corresponding PTL110 Series pick-to-light device will illuminate and display a number. The employee will grab the amount of parts needed for the installation from the correct bin. When their hand breaks the beam, a pick is recognized, and the indicator light switches off so that the next pick in the sequence can light up, alerting the employee of the following action. Using the the illuminated pick sequence as a guide reduces the chances of a worker grabbing the wrong parts or quantities.

Banner Engineering’s PTL pick-to-light devices also have PICK-IQ™, an enhanced serial communication that quickly indicates the next bin, allowing the system to keep up with the operator.

The fast speed and unique versatility of PTL110 devices have the capability to turn each station into a multiproduct assembly station for even more production efficiency. One employee can conveniently work on different pieces at the same station. Using a color-based assembly makes training fast and easy, allowing operators to quickly switch between BOMs and increase the overall throughput. The simple connectivity and brackets make the PTLs easy to move without additional tools or reprogramming.

Flexible Pick Functionality

The PTL110 series is available with optical and touch sensor capabilities for versatility in solving diverse applications. They can be used together or individually to confirm pick actions plus secondary functions. The optional display can indicate part count or provide other instructions with alphanumeric characters. Users have full control of fourteen colors and multiple animation functions so the indicator can be used to differentiate multiple conditions.

Enhanced Serial Communication

PTL110 devices are powered with PICK-IQ, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that comes from polling multiple devices. The high response speed that results works well for applications that require many pick points while maintaining a rapid pace for productivity.