Increasing Productivity with Pick-to-Light System

Manufacturing Company Eliminates Outdated and Inefficient Picking Processes

Manual part picking processes are often time consuming and prone to error. Increased demand and picklist complexity add further pressure on outdated processes. Learn how In the Ditch™, an Idaho-based manufacturer of award-winning products for the towing industry, was able to make substantial improvements to the efficiency and accuracy of their picking processes by implementing a complete Pick-to-Light system from Banner Engineering.

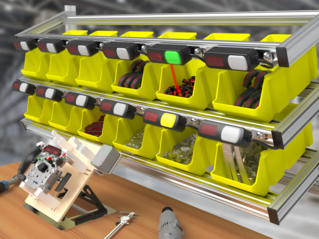

In the Ditch™ Towing Products was looking to move away from its antiquated picking system and implement a more efficient structure. Pickers used a manual process to find the proper part numbers and put the corresponding parts in the proper bins. Their existing system started when the product was placed in the hardware queue. Once the picker received a product tag, they would search for the assembly number on a laptop to open a PDF document. Once the document was open, they would memorize the part numbers, QTYs, and images of each item on the hardware list, pick those parts, and put them in the bag or bin. Pickers would repeat this process until all parts were collected for the assembly. Part pickers at In the Ditch sought an updated solution to reduce the number of mistakes made during the picking process and increase efficiency.

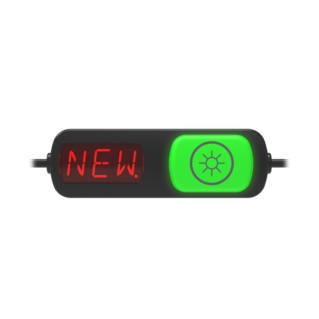

The towing company installed 400 PTL110 devices and 8 DXM700-B1 wireless controllers to update its existing picking system. PTL110 pick-to-light devices are multifunctional indicators that provide up to fourteen different colors and multiple animation functions to differentiate multiple conditions. This powerful picking system improves speed and productivity, and is powered by PICK-IQ™, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that results from polling multiple devices. The DXM700-B1 is an industrial wireless controller that offers high performance wireless communication, improves speed and memory, and facilitates Industrial Internet of Things (IIoT) applications.

“Using the pick-to-light system we can direct the picker to each item, with the correct quantity, in the most efficient order."

"We increased throughput and saw a significant decrease in warranties related to hardware issues”

- Justin Witbeck, Mechanical Engineer, In the Ditch Towing Products

Using Banner’s robust pick-to-light system, In the Ditch was able to improve picking accuracy, decrease times, and reduce bottlenecks. The system was easy to install, and the parts were quickly connected and programmed to accomplish the company’s goals. Operators at In the Ditch found that Banner’s service and technical support, coupled with Landmark Industrial Service’s integration, provided a complete solution. They also found that it was much easier to train new employees on the upgraded process.

Fast, Scalable Solution to Maximize Productivity

PTL110 pick-to-light devices are powered by PICK-IQ™, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that results from polling multiple devices. The fast response speed at scale makes PTL110 an ideal solution for production lines and fulfillment stations that require many pick points, while maintaining a rapid pace to exceed productivity targets.

Solve more applications with flexible pick functionality

PTL110 models are available with optical sensor and touch button capabilities for versatility in solving diverse pick-to-light, put-to-light, and kitting applications. These functions can be used individually or together to confirm standard pick actions plus secondary functions. The optional display can be used to indicate part count or provide other instructions with alphanumeric characters. Users have full control of fourteen colors and multiple animation functions to clearly differentiate multiple conditions.

Reduce costs with simple mounting and installation

Each PTL110 device has two M12 connectors for quick and secure installation of multiple devices with no additional cables required. Connect device-to-device or add standard patch cables to fulfill your application requirements. PTL110 devices can be fastened to tubes, extrusion, and rail with a variety of brackets or standard cable ties. They can be quickly moved and replaced with no tools, rewiring or reprogramming required.

Become a smarter factory

The DXM700 can be used for various IIoT applications such as remote monitoring, predictive maintenance, or process optimization. The DXM700 is compatible with Banner sensors and Cloud Data Services software to create complete end-to-end IIoT solutions.