Motor Detection

Challenge

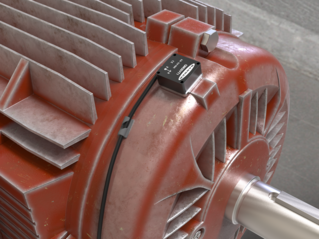

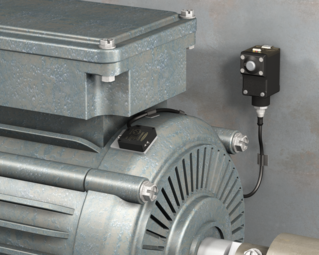

As motors move along the manufacturing line, accurate component installation is vital to the integrity of the final product. Correctly detecting and indexing palettes—which carry the motor casing—aids component installation.

Once palette detection occurs, the motor casing, called a motor stator, must be detected to ensure manufacturing proceeds as intended. High performing, durable sensors are needed to withstand an industrial, rugged environment for detection of the palette and motor stator.

Solution

The robust housing of Banner’s powerful TM18 sensor is ideal for machine assembly and transport, preventing damage to the sensor while providing extremely accurate, reliable detection with opposed mode sensor pairs. Banner’s TM18 is rated to IP69K with a nickel-plated, die-cast zinc design, providing heavy-duty protection to the sensor in an industrial, automotive environment.

The TM18 Series, with a right angle shape and 18 mm threaded barrel mount, easily fits into limited space setups for simple installation on the manufacturing line. The extremely bright LED emitter also makes alignment to the receiver quick and easy.

Multiple modes are available, including fixed field and diffuse for enhanced immunity to fluorescent lighting, and opposed and polarized retroreflective modes for maximum sensing reliability. Additionally, the TM18 sensor is available with four-wire NPN/PNP output models or three-wire I/O block compatible outputs.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)