Extendable Reach Conveyor

Challenge

Distribution centers typically have multiple freight shipping and receiving areas. These areas are usually surrounded by material handling systems including extendable reach conveyor platforms.

These conveyors are used to “reach” inside of the container, enabling faster unload/load operations, reducing movement time compared to a fixed conveyor. A solution is needed to ensure the extendable conveyor does not extend too far into the truck, which could cause carton and product damage.

There is also a lack of light inside the container, which creates a potentially hazardous work environment as well as an increased likelihood of carton damage while the unit is being extended. Lighting is required to adequately illuminate the inner part of the container.

Solution

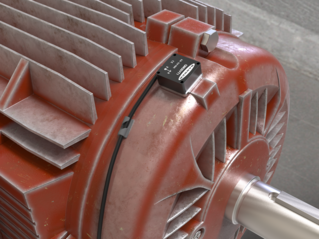

Banner provides sensing and industrial LED lighting solutions to help minimize carton and product damage inside a container. Banner’s QS18FF with background suppression has a fixed range up to 100 mm with an 850 microsecond response time, allowing for easy detection of the packages/cargo and ensuring the extendable conveyor does not crush cartons.

Banner’s WLB32 is a cost-effective, LED lighting solution available in both AC and DC versions with a high lumen output that ensures proper illumination of the cargo container interior. The dual-position switch allows for operator preference and provides a soft white-focused light. The WLB32 industrial LED light bar is available in four lengths and is energy-efficient, allowing for reduced overall energy costs.

Banner is a worldwide leader in industrial automation, with expertise in sensors and advanced LED lighting technology. The QS18FF sensor coupled with Banner’s WLB32 LED light bar provides high-quality solution with superior performance for applications in a distribution facility.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)