Communication in a Busy Manufacturing Site

EZ-LIGHT® Touch K50 button and EZ-LIGHT® TL50 tower light used to facilitate communication from unloading to loading operator of industrial oven

Customer Requirements: Clear communication between operators to manage the pace at which parts are loaded and unloaded

Solution: EZ-LIGHT® Touch K50 button and EZ-LIGHT® TL50 tower light

Why Banner? Customization – Modified tower light in loading area mirrors touch light status assigned by operator in distant, hard to see unloading and sorting area

Simplicity – Indicators are easy to install and wire and require no programming or PLC for operation

High Visibility – LED light display is easy to see at a distance, even in daylight bright conditions

Customer Benefits

Visible Communication – At-a-glance indication of unloading station status throughout the production area enables remote monitoring of component flow

Efficiency – Reductions in misdirected and damaged parts streamlined flow of components through work stations

Performance – Low-power, energy efficient LED indicators offer superior visibility and years of reliable operation with minimal service required

Background

An innovative leader in the manufacture of auto parts makes engine, transmission and other high-tech products for the global automotive industry. During the hardening process, aluminum components are loaded onto a conveyor traveling through a large industrial oven. In the time required to travel the length of the oven the component will have completed a heat treatment cycle. It is then removed from the conveyor, sorted and eventually transferred to a work station.

Challenges

As more components pass through the oven, keeping pace with the flow of items to be unloaded becomes increasingly difficult. Congestion in the sortation area builds. Items can easily be misdirected or even damaged. A pause in the flow of parts allows the unloading operator to correct mistakes and clear a pickup station. However, the distance between the unloading and loading areas as well as ambient interference from surrounding machinery complicates communication between operators.

Solution

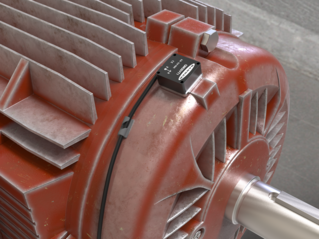

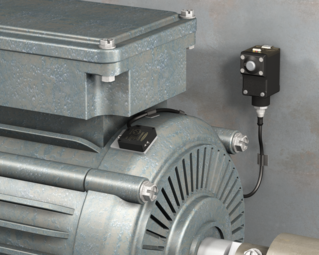

A two-color EZ-LIGHT® Touch K50 button was installed on the unloading side of the oven. The system was easy to install and wire; all that was required was to mount the brackets and wire the 2-wire DC lights. On the loading side of the oven the company deployed an EZ-LIGHT® TL50 tower light modified to emulate the status of the K50.

When the unloading operator depresses the K50 button it causes the button and the tower light to illuminate red, signaling the loading operator to stop. Pressing the button again changes the status on both lights from red to green, signaling the operator to resume loading. Additionally, the K50 lighted button provides the unloading operator with an easy to see status reminder, ensuring communication clarity and reducing downtime due to false restarts. The high visibility illumination offered by Banner’s EZ-LIGHT series makes it possible to visually check the tower light for operator status at the oven throughout the production area, even in daylight bright conditions.

The implementation of the Banner LED indicator lights enabled clear, visible communication in a challenging environment. The unloading operator is able to give clear visual indication to the loading operator to cease or resume loading components. During pauses in product flow, the unloading operator can sort and clear parts, minimizing area congestion and component misdirection and opportunities for damage to occur. Overall production efficiency improved as more of the correct parts were transferred to the correct work areas without requiring redirection.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)