Monitoring Plastic Tray Levels on a Denester Machine

Application: Monitor stack height of plastic food trays

Challenges: High-speed movement of trays in a washdown setting

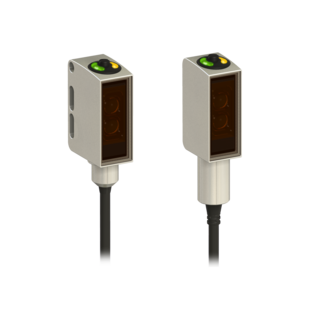

Solution: QM26 Washdown Photoelectric Sensor

Benefits: Rugged, stainless steel housing with a IP69K rating

A tray denester stores and singulates plastic trays at high-speeds. Any interruptions or errors on the machine can decrease production and cause unwanted downtime. A solution is needed to monitor tray levels while maintaining quality in a stringent washdown environment with specific cleaning requirements.

Description

A denester removes one food tray from the stack at a time and moves it onto the conveyor line infeed. Monitoring tray levels helps maintain high throughput along the food processing line because it informs operators of low tray levels before the machine is completely empty.

Banner Engineering’s QM26 Washdown Photoelectric Sensor is a great fit in this washdown environment. The QM26 is made of rugged, non-toxic 316L stainless steel and rated to IP69K making it ideal for applications typically found in the food industry. In fact, the QM26 Series sensor is composed of FDA compliant materials. It was created with a smooth hygienic design in mind to prevent debris build up and make cleanup easy.