Lithium-Ion Battery Electrode Film: Roll-Diameter Measurement

Challenge: In EV battery manufacturing, electrode material comes in the form of a thin plastic film, which is supplied in large rolls. During the slitting and die-cutting process, rolls are monitored to detect jams or low-material. Electrode material presents challenging dark and reflective targets for traditional sensors, so choosing an accurate sensor that meets your specific application is critical.

Solution: Banner offers several measurement sensors based on requirements such as sensing technology, accuracy, range, and output type.

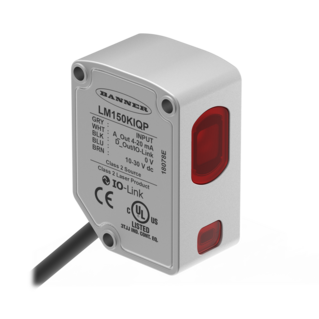

Lasers can offer the best accuracy and resolution but aren’t always an option if the material can’t be reliably detected due to its reflective properties. In these cases, an ultrasonic or radar sensor can be used. These technologies are unaffected by the target’s color or irregular surface qualities. In many cases, high-gain laser sensors are a good fit if accuracy is the most critical factor: Banner’s LM-series sensors have resolution down to 0.002 mm. Other laser sensors such as the LE-series have a longer sensing range (1m) while maintaining 1mm resolution.

Banner sensors offer a variety of output types ranging from a basic, discrete signal (indicating that the electrode-material-film roll is above or below a certain diameter) to analog and even IO-Link outputs that provide real-time measurements.

All sensor setup is done from the device itself or with a remote sensor display (RSD) tool. In either case, users may easily configure output types, response speeds, sensing ranges, and more. Banner sensors use industry-standard M12 connections. After selecting the best sensor for your application, check out the accessories section on the product page for compatible cables to complete your solution.