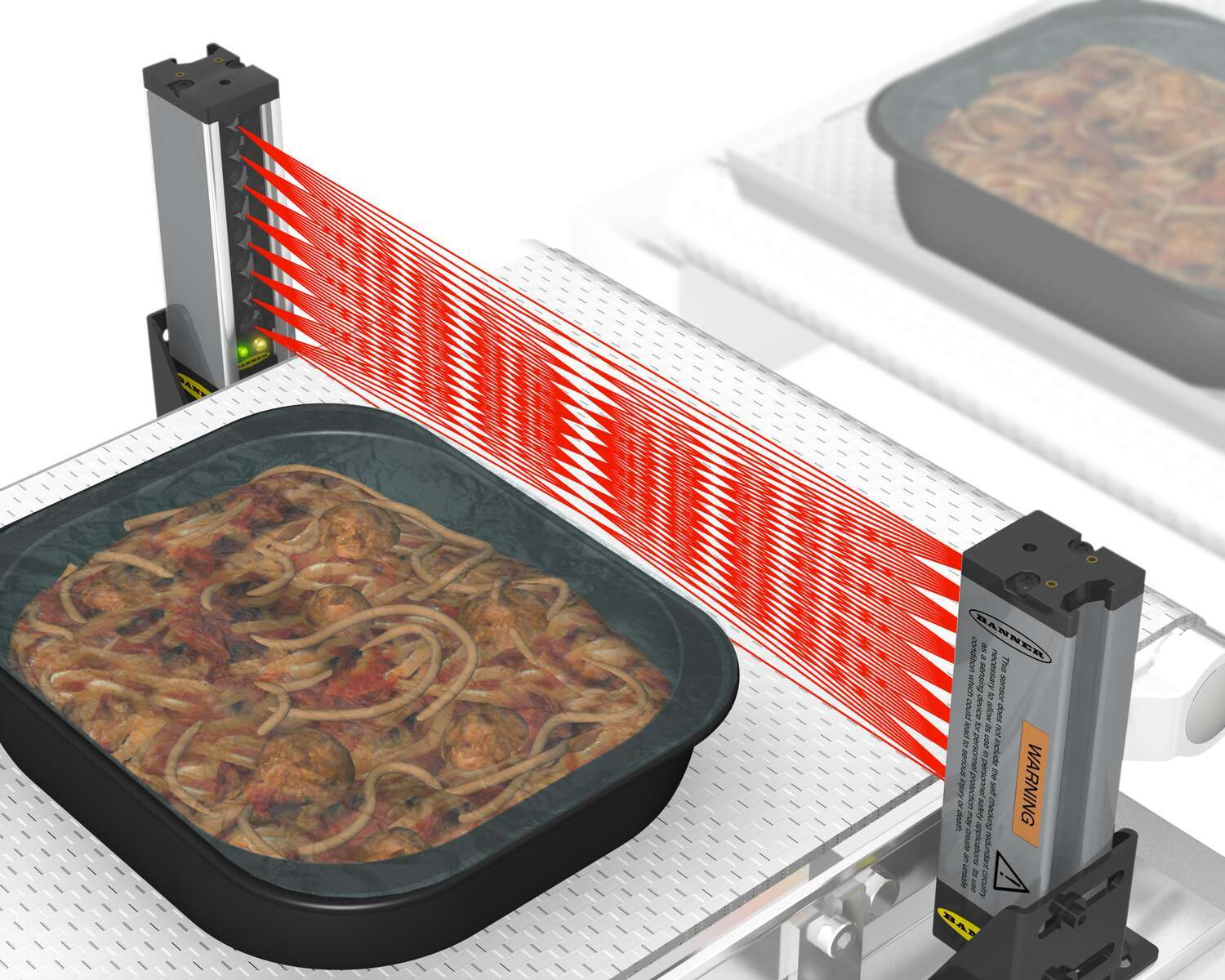

Leading Edge Detection of Packages with a Thin, Flexible Edge

Application: Detecting the leading edge of plastic food containers

Challenges: Trays may vary in position

Solution: LX series part-sensing array

Benefits: Emits a web of modulated light that can detect items in any position as they pass through

Frozen dinners go through many processes during secondary packaging before being stretch wrapped in large boxes for shipment. As frozen dinners come down the line, it’s important each dinner be individually placed into a bucket, so it can enter the carton magazine correctly. Detecting the leading edge of the plastic container - which is usually thin and can vary slightly in position - is essential to isolating dinners into buckets. This process requires a solution that can swiftly detect small objects that may or may not be in the exact position as the previous object.

Flat Edge Detection of Plastic Frozen Dinner Trays

Banner Engineering’s LX Series is an economical solution for detecting the leading edge of flat objects, such as the frozen dinner containers. With a web of modulated light, the LX Series part-sensing light screen can detect any item in any position that passes through the beams.

The LX Series’ response rate 0.8 to 3.2 ms prevents sensing delays and keeps the conveyor moving at the optimum speed for placing dinners in the bucket. With easy-to-see, bright LEDS on the emitter and receiver, data monitoring and processing is simple.

The wiring configuration is straightforward and efficient because the emitter and receiver do not require a synchronization wire. The LX Series’ bipolar design offers NPN and PNP solid-state outputs with a rugged, self-contained housing.