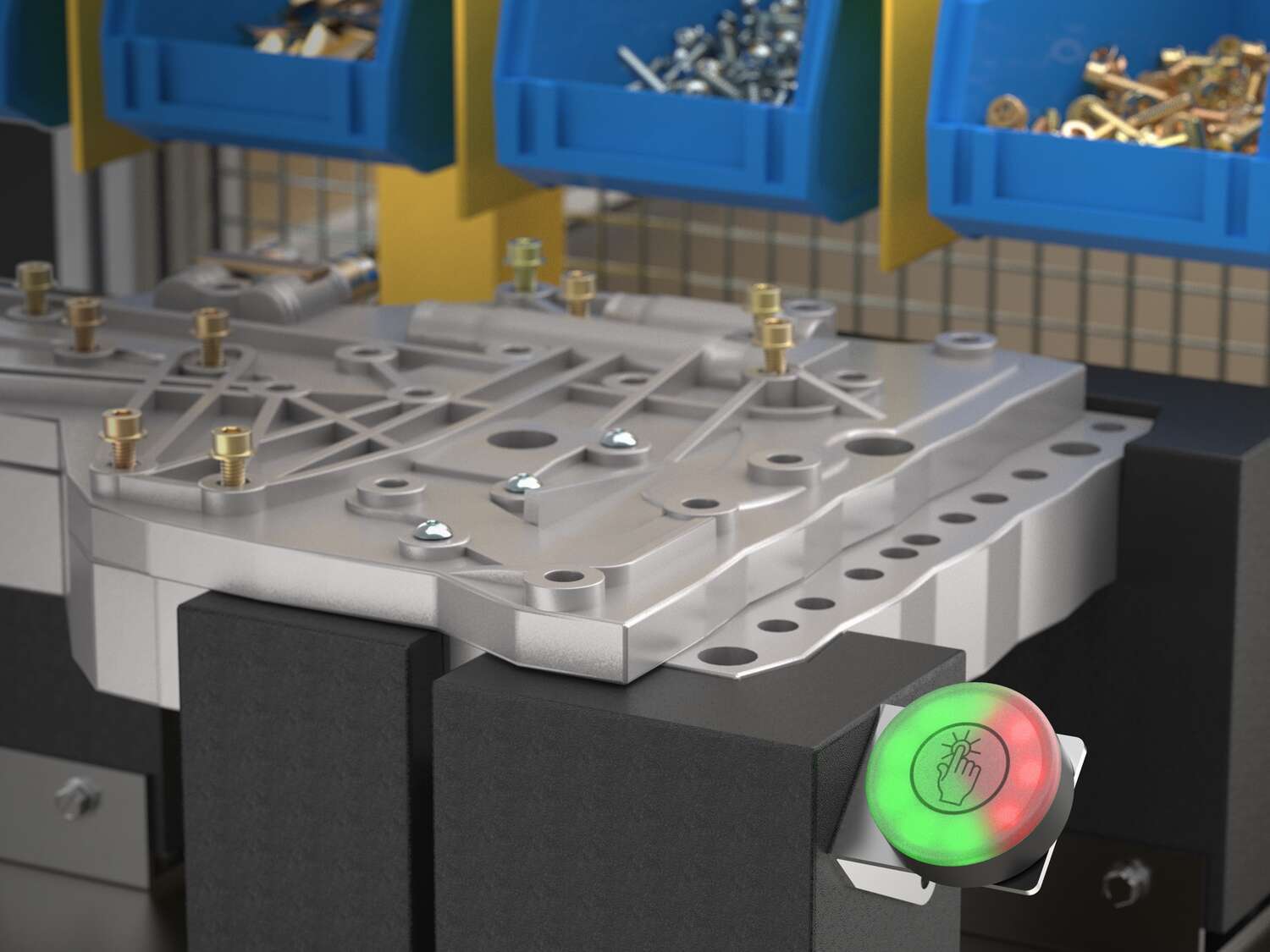

Assembly Timer at Busy Work Station

There are numerous different assembly stations throughout the production line and slowdowns at any of these areas could create larger problems further down the line. To ensure that workers continue to meet takt time for optimal efficiency, a solution is needed that can act as a timer and alert workers of the remaining time to complete their task. The following article explains how K50 Pro touch button with IO-Link can be used at workstations to help assemblers meet overall production goals.

Manual assembly processes are frequently found on production lines and are an integral part of manufacturing. It is necessary for assemblers to maintain a consistent pace to hit production goals and keep assemblers further down the line supplied with parts. However, employees may not be aware of their own production pace and whether they are working quickly enough to stay on track. If their pace is too slow, it slows down the entire assembly line and goals are not met.

Takt time is important to manufacturers because it represents the rate of production that is needed to match demand. Keeping production rates in accordance with the estimated takt time is a simple way to maximize profits.

Using the IO-Link compatible K50 Pro touch button is an easy way to ensure that operators are maintaining takt time. Sequence mode is included with IO-Link models and can be used as a timer. Each LED can represent a specified number of seconds and the K50 Pro touch button is programmed to remain green until the last few seconds. At this point, the LEDs change to red to alert assemblers that they need to finish their task soon.

With this individual LED control, the K50 Pro touch with IO-Link offers more advanced functionality when compared to ordinary touch buttons. The bright LED lights are easy-to-see and installed directly in user's sightlines for increased efficiency and less distraction from the task at hand. The buttons can be programmed to have multiple colors – up to fourteen variations – and animations for additional customization.

Lighting and indicators that are compatible with Banner’s Pro Editor software are already very versatile and the K50 Pro buttons now have models with IO-Link for further flexibility in solving applications. IO-Link compatible products have simplified wiring and make remote monitoring easy. The increased efficiency afforded by IO-Link reduces machine downtime and excess costs.

K50 touch buttons are also designed to be very rugged to prevent damage in demanding industrial environments. They are rated IP67 and IP69K for use in wet or high-pressure washdown environments. The Pro touch buttons also feature adjustable touch sensitivity to ensure buttons are not triggered during washdown.

Flexible Customization

Touch buttons can be easily customized with a wide variety of color and animation options to give your machine more versatility and intuitive features. Users can also reduce touch sensitivity levels to avoid false trips in washdown areas.

Streamline Supply Chain

Pro Editor software enables users to program units in the field as needed and adjust the touch button capabilities. Models can be programmed as needed with multiple colors and animations, simplifying inventory requirements by reducing the variety of part numbers that must be stocked.

IO-Link Compatible

IO-Link communication further adds to the versatility of the K50 Pro touch buttons by providing remote monitoring capabilities on the field device level. With IO-Link, the information collected from the K50 Pro touch can be easily accessed by operators or plant managers and used to monitor such things as assembly line productivity.