-

Products

-

Industrial Wireless

-

Reference Library

-

Solutions Guides

Solutions Guides

These guides detail common applications built around the DXM100 Wireless Controller and a range of Banner wireless products.

Each guide provides an overview of the application, equipment used, features and benefits, and step-by-step instructions for implementation, including:

- Binding the radios

- Running a site survey

- Accessing and loading the XML and Script files

- Making site specific customizations

- Sending information to the Sensonix Webservices cloud

Downloads

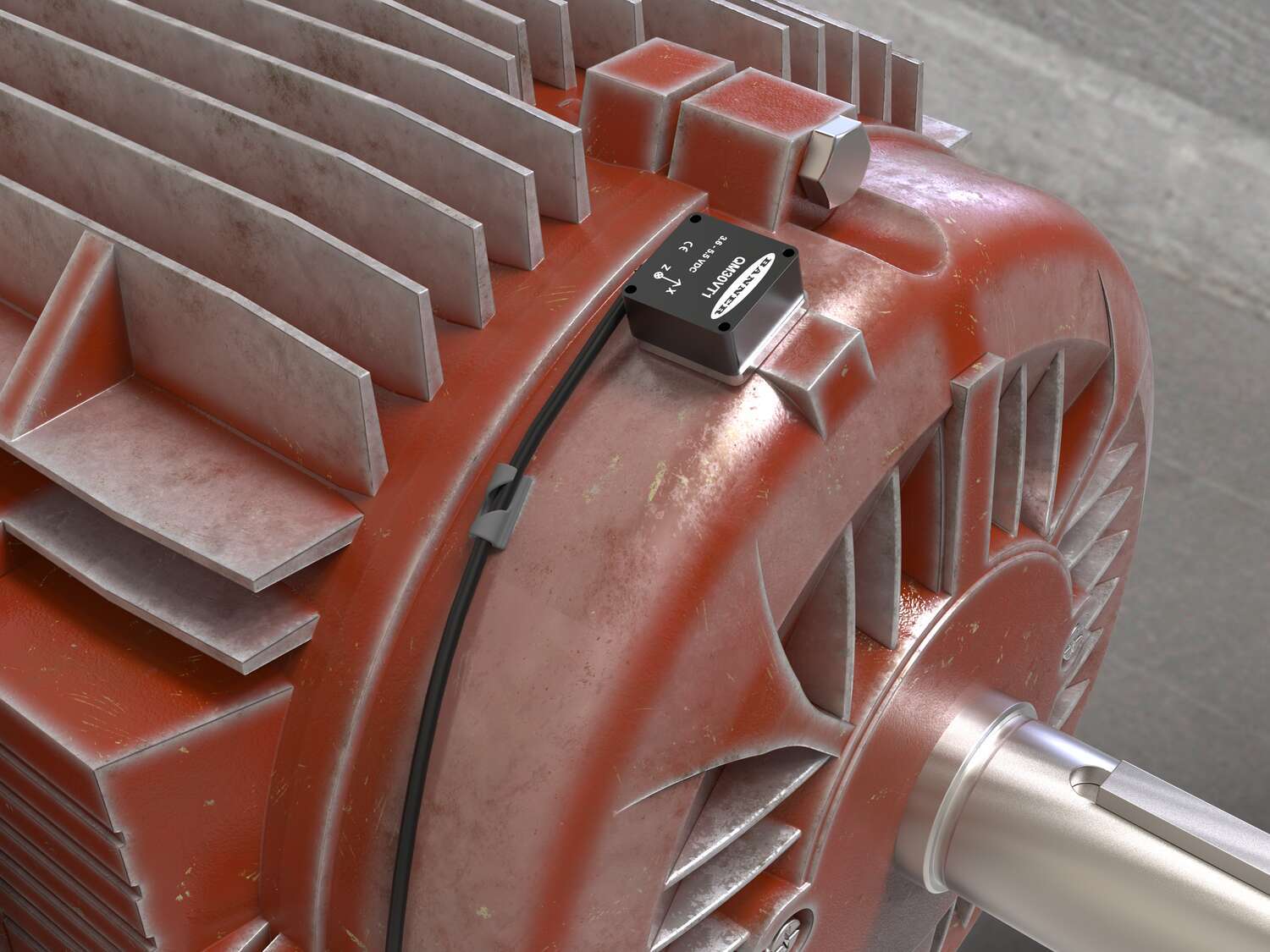

Vibration and Predictive Maintenance

Continuously monitoring vibration data can minimize downtime, allow you to track up-time, and send alerts to needed maintenance to avoid costly failures. This guide provides continuous monitoring of two critical vibration characteristics on both the X and Z axis of up to 40 motors using a QM30 Vibration Series Wireless Sensor.

This solution creates a “Check Engine Light” for each motor using in-depth analysis to indicate unusual characteristics without end-user interaction.

Tank Level Monitoring

Using K50U Ultrasonic Sensors and Q45U Wireless Nodes or the All-in-One Q45UA* Sensor Nodes paired to a DXM100 Wireless Controller, we can develop a wireless monitoring system for multiple tank level measuremUsing K50U Ultrasonic Sensors and Q45U Wireless Nodes or the All-in-One Q45UA* Sensor Nodes paired to a DXM100 Wireless Controller, we can develop a wireless monitoring system for multiple tank level measurements that is easy to set up, interpret the results, and monitor locally and through a cloud-based system. ents that is easy to set up, interpret the results, and monitor locally and through a cloud-based system.

Temperature and Humidity Level Monitoring

Using the M12FTH Temperature and Humidity sensor connected to a Wireless Q45 Node or All-in-One Temperature and Humidity Sensor Node paired to a DXM100, we can develop a wireless monitoring system for multiple environmental measurements that is easy to set up, interpret the results, and monitor locally and through a cloud-based system.

Call for Parts, Pallets, or Service Pickup

Increase production efficiency by developing a wireless call-for-parts/service/pallet pickup system that allows for up to 18 work stations to call out to six forklifts/Hi-Los using the EZ-Light K70 Touch to wireless Q120 6-Button Pendant. This provides for quicker responses from forklift drivers and/or supervisors to indicate a request has been accepted. When creating a call system using wireless indicators, work stations can maintain a steady workflow and resolve critical issues quickly.

Machine Monitoring/Overall Equipment Effectiveness

Using a TL70 Modular Tower Light with a wireless radio base improves machine monitoring and overall equipment effectiveness (OEE) by expanding available data beyond the local indication a standard tower light provides.

High Speed Parts Counting and Parts Counting for OEE

Increase production efficiency by monitoring multiple part counts with to up 16 wireless Performance Nodes. The high-speed asynchronous totalizing done by the DX80-P16E Node gives the ability to totalize up to 10,000 parts per second. Monitoring the current state of part counting inputs along with parts per minute rates can be used to establish errors or inefficiencies in the system.

Wirelessly track parts flow to measure and analyze OEE metrics of availability, performance, and quality to compare how your process/machine is performing against an ideal state.

Motor Control

Remotely control up to 12 motors using two wireless Q120 Nodes and 12 single input/single output wireless Nodes. Track motor status, motor run time, the count of times that a motor was turned on, and the status of the auxiliary input.

Loading Dock and Mobile Pick-up

This guide provides the ability to monitor and track a combination of up to 24 M-GAGEs or U-GAGEs through the DXM100 while providing indication through up to four wireless TL70 tower lights with six light segments on each. The local light indication can save time and money when action is required upon a vehicles arrival. It can also provide overall metrics to track and improve performance of the actions being taken. Application examples include loading docks and mobile pick-up areas.