PVD Series

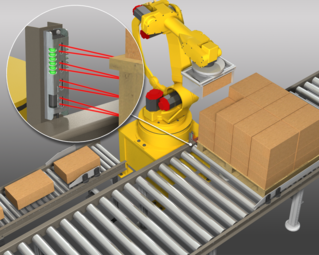

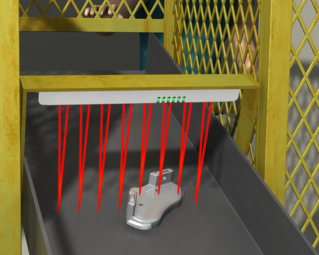

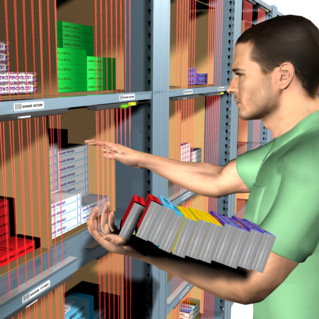

Single Piece Part Verification Array

- One-component system, easy to mount and even easier to use

- Automatically operates in either diffuse or retroreflective mode, depending on the application

- Automatic setup and adjustment; wide beam pattern provides easy alignment

- Range up to 2 m (6.5 ft) when used with retroreflective target; 400 mm (15.7 in) when used in diffuse mode

- Large job lights on either side of the metal housing can be remotely controlled to initiate user action with a solid or a blinking green light; job lights turn red to indicate bin-picking errors

- Compact package size; only 30 mm wide x 15 mm deep (1.2 in x 0.6 in)

- Available in 2 lengths to fit existing parts bin sizes and configurations

- Heavy-duty protective brackets available

Downloads

Software

Date

Type

Size

Marketing Literature

Date

Type

Size

Date

Type

Size

Date

Type

Size

Date

Type

Size

Date

Type

Size

Date

Type

Size

Date

Type

Size

Date

Type

Size

Date

Type

Size

Product Selection