Intelligent Mail Industrial Barcode Reading

The iVu BCR is used in many mail applications to help direct mailers from multiple smaller runs as they are combined into larger ones.

The iVu and iVu Color Image Sensors are used to monitor parts for type, size, orientation, shape, location, and color or color variations. The device can be set up and monitored using an integrated or remote touchscreen or with a PC. The following features are available:

Vision Sensor: iVu Series

The iVu BCR is used in many mail applications to help direct mailers from multiple smaller runs as they are combined into larger ones.

To detect this mark, use an iVu Series sensor configured for a Match inspection. The sensor detects the end-of-bundle mark, and signals the bundling machine to wrap the finished group.

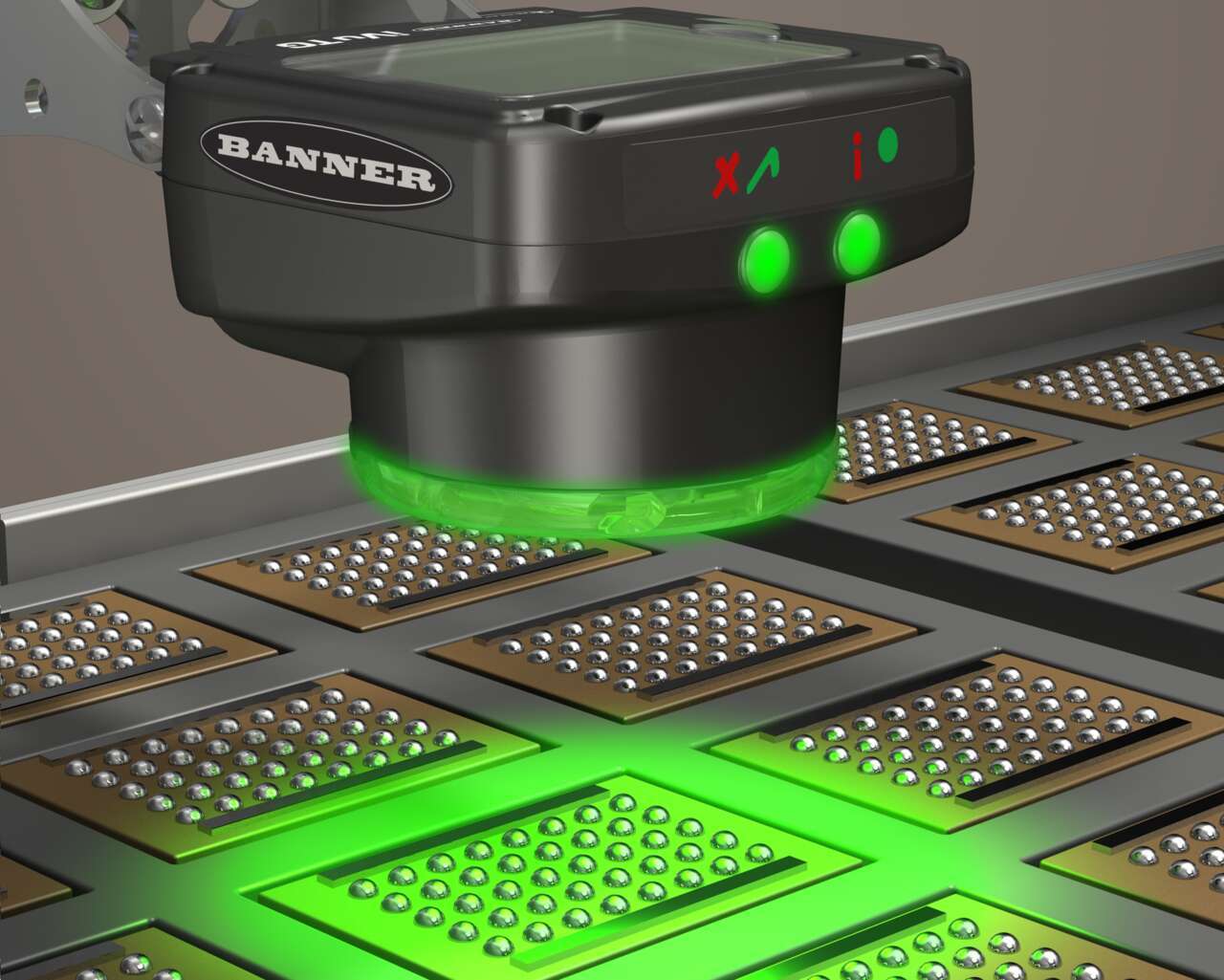

To verify each integrated circuit, this application uses an iVu Series sensor configured for an Area with Motion application. If the sensor detects a part with missing or damaged solder balls, or if it detects any foreign material, the sensor sends a fail output to the line, and the part is rejected.

This application uses an iVu Series sensor configured for an Area inspection. When holes are punched, the sensor evaluates all the holes to make sure that they are present and correctly sized. If any are not, the sensor sends a fail output to the line where the part is rejected.

To verify each product, an iVu Series sensor is configured for a Match inspection. An image of a good product package is captured. When the inspection is running, if the sensor detects a package with a different or missing label, the sensor sends a fail output to the line, and the product is rejected.

An iVu Color Sensor identifies RGB values of individual pieces of trim on vehicle door panels and communicates this information over an industrial Ethernet connection to a PLC.

This application uses an iVu Series sensor configured for a Match inspection. It ensures that the music label is face up and within a small rotational tolerance. If the sensor detects a CD that is incorrectly oriented, it sends a failure to the line, and the CD is rejected.

The solution uses an iVu Series sensor configured for a Match inspection. A reference "good" identifier is taught into the sensor. In service on the production line, the sensor detects when a component does not have the correct identifier, and sends a fail output to the line, and the part is rejected.

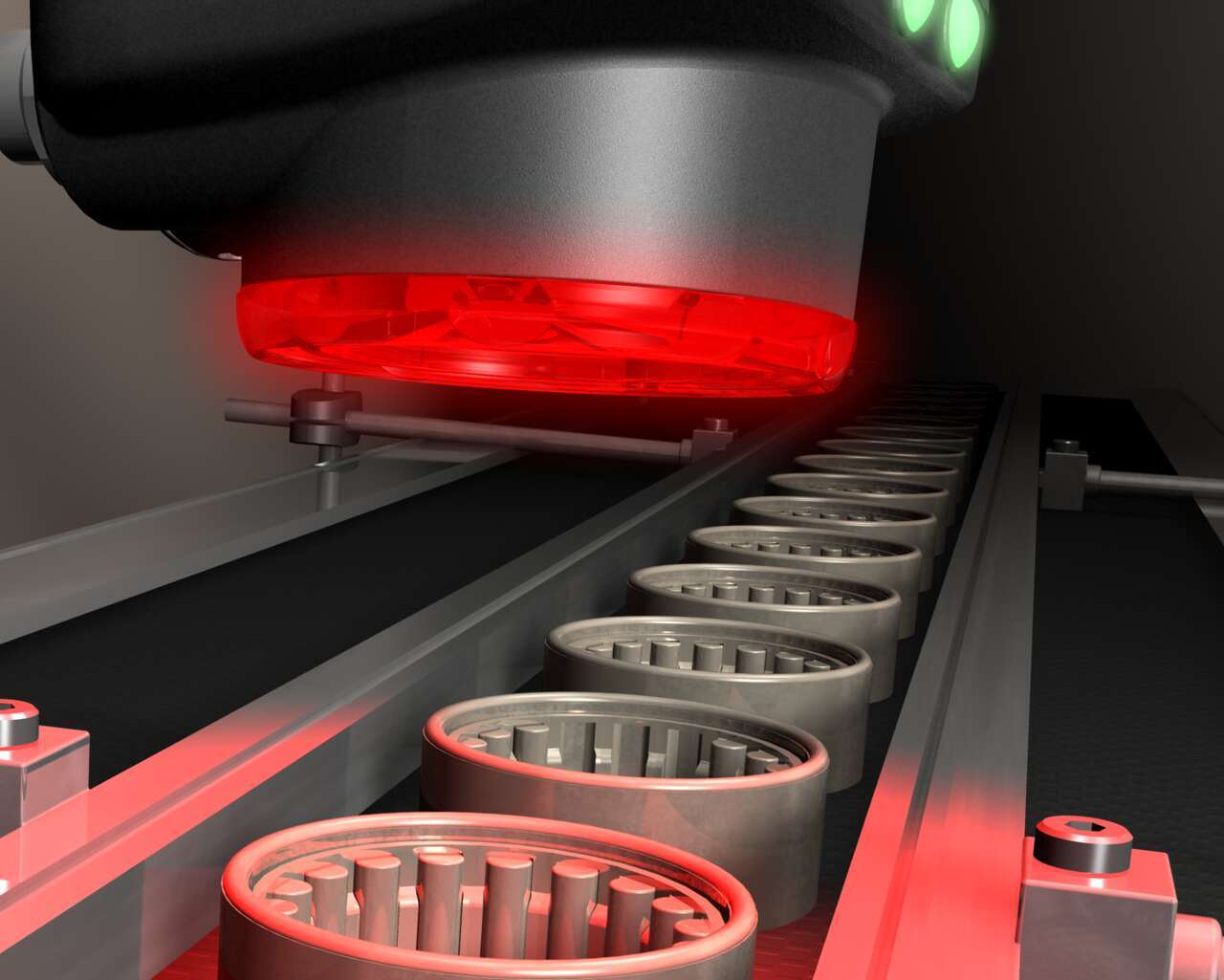

The solution involves using an iVu Series sensor configured for a Match inspection to ensure that all the bearings are present for each component that includes the bearing assembly. If the sensor detects one or more missing bearings, it sends a fail output to the line, and the component is rejected.

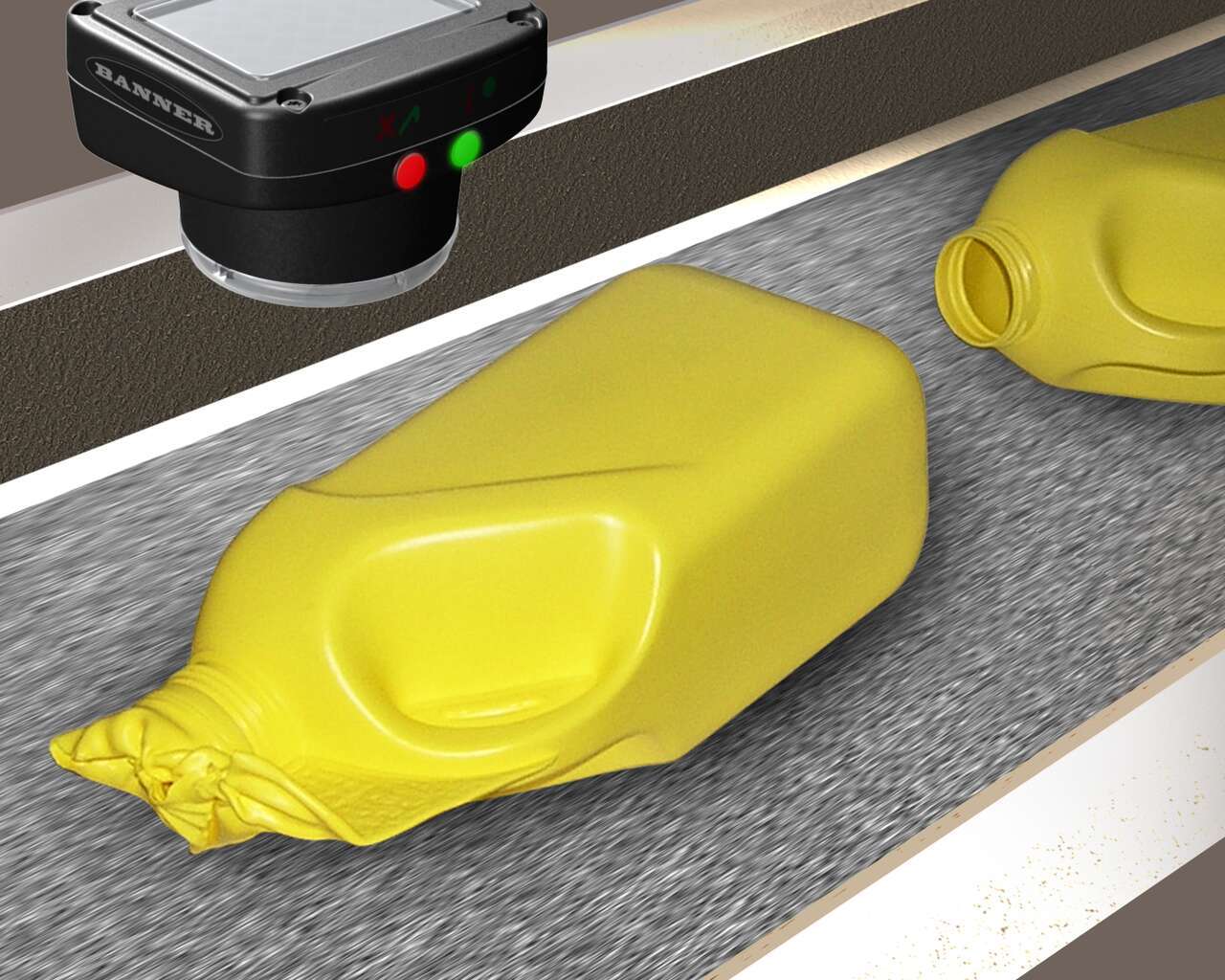

The solution involves using an iVu Series sensor configured for a Match inspection. The sensor evaluates each plastic bottle and, if the bottle is not well formed, the sensor sends a fail output to the line where the plastic bottle is rejected.

Bottles incorrectly packed into bliss trays for sale in club stores did not properly display product labels and had to be returned to the company.

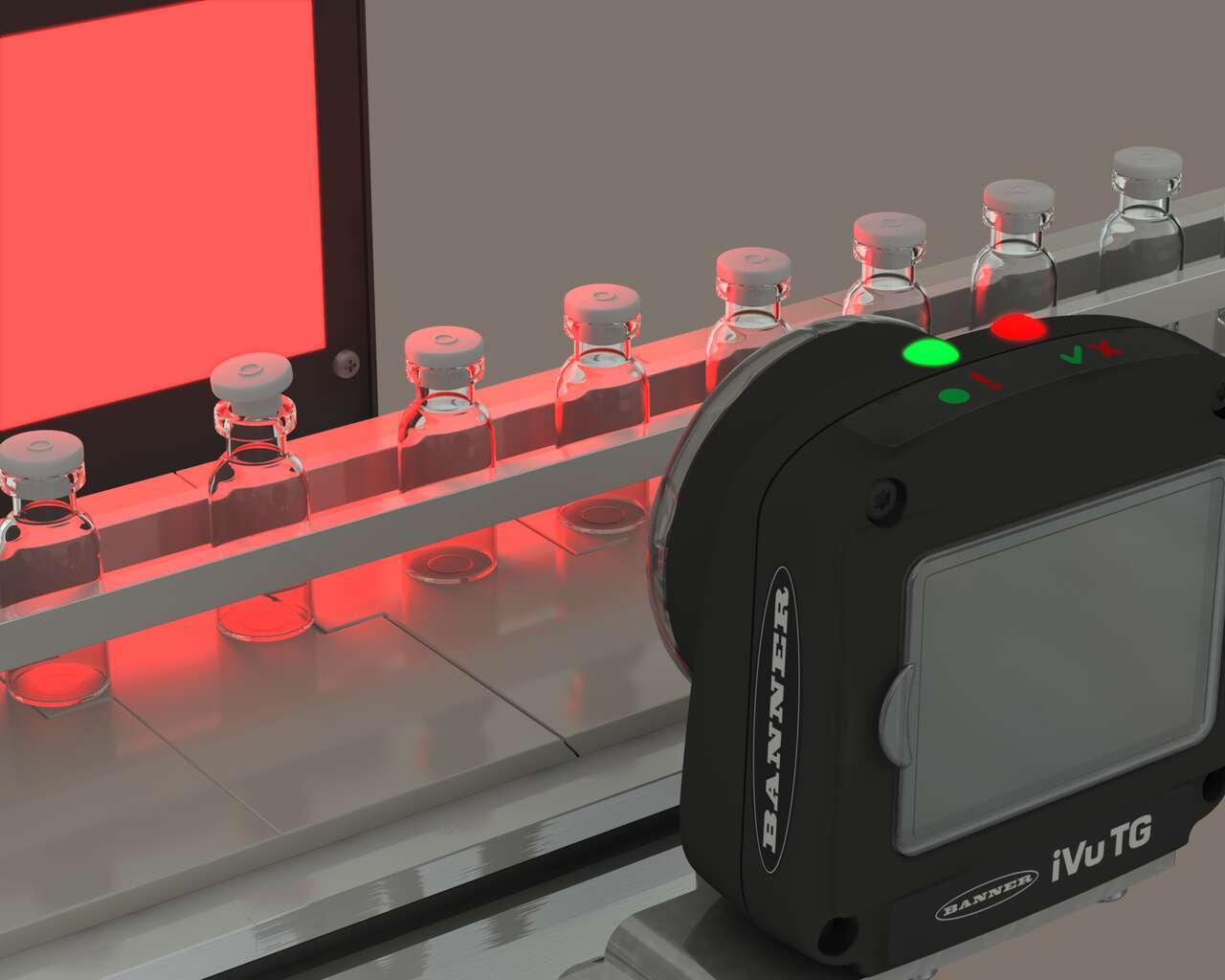

An iVu TG Image Sensor works well for label verification because it comes with four sensor types, including a match sensor. The match sensor determines whether a pattern on a label matches a reference pattern and if it is correctly oriented. With just the touch of a button—or remotely through a PLC—users can easily teach the iVu image sensor to recognize and match the correct label pattern, requiring no image processing expertise.

An SLM series slot sensor and an iVu Series vision sensor are used to detect bottles passing on the line and to verify that date/lot codes have been correctly printed onto the bottles.

An iVu vision sensor inspects nuts exiting a vibratory feeder bowl to ensure that the correct side of the nut faces up. The iVu features an intuitive operating environment that makes it easy for users to quickly apply and support inspections on the device.

To verify that the expected number of holes exist on a small metal part that is not rigidly fixed, use an iVu Series sensor configured for an Area with Motion application. When holes are punched, the sensor evaluates all the holes to make sure that they are present and correctly sized. If any are not, the sensor sends a fail output to the line where the part is rejected.

Banner Engineering’s iVu vision sensor inspects presence vent tubes and spreader washers on a busy bottling line. It uses a 50 mm C-Mount lens to extend the working range of the sensor to avoid contact with spray and liquids.

As each salad dressing bottle leaves the label station, an iVu Series vision sensor, configured to use the Match tool, inspects the label, comparing it to a preconfigured reference image to ensure that the label is present and has been correctly applied.

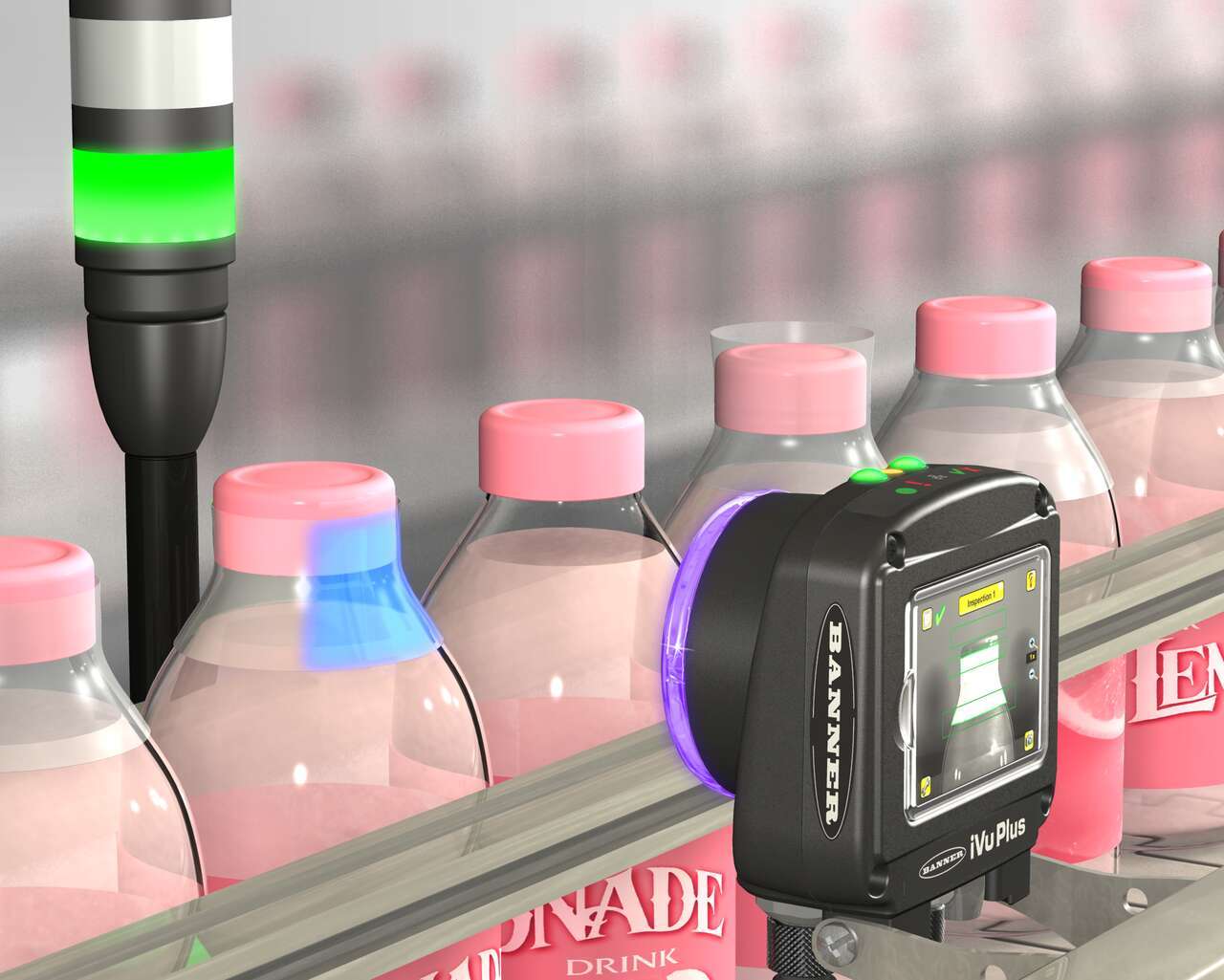

To ensure that product quality standards are met and that product appearance is consistent with the brand, the company must inspect each bottle to ensure that the right bottle cap is present and properly seated.

• Confirm presence and orientation of IC chips</br> • Sensor performs multiple functions at once</br> • Cost savings and versatility</br>

To verify each box is correct, an iVu Series sensor is configured for a Match inspection with 360 degree rotation enabled. An image of the correct box is captured and when the inspection is running, if the sensor detects an incorrect box, the sensor sends a fail output to the line, and the product is rejected.

The company was experiencing several quality control issues—bottles were coming off the line with missing, skewed and double labels. As a result, the customer was scrapping over 2,000 bottles a month, a process which requires them to cut out the mislabeled portion of the bottles and re-grind the plastic for reuse. Further, the labeling errors began prompting serious customer complaints. To avoid scrapping additional bottles and losing loyal customers, the company came to Banner for a label inspection solution.

A high-volume brewery needed a solution capable of detecting spreader washers on the vent tubes as well as loose or missing tubes. However, the movement of the rotary filler and the wet washdown environment made close proximity deployments difficult and the range required for a remote solution could compromise inspection reliability.

To verify each blister in the pack, use an iVu Series sensor configured for an Area inspection. The sensor inspects each blister pack to make sure that each blister contains an unbroken tablet.

iVu Series vision sensors are ideal for monitoring materials to ensure that specific quality standards are met. It provides users with complete control and immediate feedback for setup and monitoring of products. It features multiple sensor types, including a blemish sensor, which is the best mode for this application.

To confirm that each unit includes a product information insert, an iVu Series sensor is mounted above the packaging line. The sensor is configured for a Match inspection, and checks that the product information leaflet is inserted into each package of medication. The leaflet can be placed in any orientation, but must beface up.The sensor can detect 360 degrees of rotation to find the insert.

To ensure that a stopper is properly inserted as each vial leaves the filling station, an iVu Series sensor—set up for an Area with Motion application—verifies that the vial has a stopper inserted into its neck and that the stopper is positioned correctly to provide a proper seal on the glass vial. If the stopper is missing or incorrectly positioned, then the sensor sends a fail output to the line.

Banner iVu TG vision sensor with multi-point inspections is ideal for detecting and evaluating the position of tamper-evident bands. In this application, the band should be positioned around both the cap and the neck of a bottle. A seal positioned too high, too low, or completely missing would be considered unacceptable. With multi-point inspection, the iVu TG vision sensor can simultaneously detect missing and poorly positioned bands.

To verify each package has a date/lot code printed on it, an iVu Series sensor is configured for a Match inspection. An image of the date/lot code is captured. When the inspection is running, if the sensor detects a package without the date/lot code the sensor sends a fail output to the line, and the product is rejected.

• Confirm presence and orientation of IC chips</br> • Sensor performs multiple functions at once</br> • Cost savings and versatility</br>

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

![iVu Series Vision Sensors [Video]](/content/dam/banner-engineering/projects/video-thumbnails/i_Vu_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

iVu Series vision sensors combine the simplicity of a photoelectric sensor with the intelligence of a smart camera. They can be used to monitor parts for type, size, orientation, shape, location, and color or color variations.

Watch the video to see the iVu vision sensor and TL50 Pro tower light in action.

This tutorial video provides an overview of Banner's iVu Plus TG display and provides instructions regarding the user interface.

This tutorial is intended to help you set-up and monitor an inspection with more than one sensor. Multisensor inspection is possible if you download the latest Firmware software.

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.