- Banner’s free and easy-to-use Vision Manager Software provides a number of tools and capabilities that enable VE Series Smart Cameras to solve a wide range of vision and identification applications, such as item detection, part positioning, flaw analysis, quality assurance, traceability, etc.

- Available in 5MP (2592 × 2048 pixels), 2MP (1600 x 1200 pixels), 1.3MP (1280 x 1024 pixels), and WVGA (752 x 480 pixels) models, all with the same powerful inspection and/or identification capabilities

- Runtime editing capability reduces costly downtime and the software emulator allows for offline building and troubleshooting of applications

- Factory communications (EtherNet/IP, Modbus/TCP, PROFINET, and Serial RS-232) for integration on the manufacturing floor

- Six optically isolated I/O and the ability to power and control external lighting

- Onboard display provides inspection information makes it easy to update sensor settings, facilitating fast product changeover

- Robust metal housing with optional lens covers to achieve IP67 rating for use in harsh environments

Literature

Technical Literature

Product Data Files

PLC Support Files

Brochures & Catalogs

Software

Software

Software Archives

Application Notes

Detailed Inspection on a Sortation Conveyor

In large distribution facilities, sortation trays deliver products to the proper bin for correct shipment. Before sorting can begin, each tray needs to be empty so that items can be placed on the conveyor and sent to the next location. The 5mp VE Smart Camera recognizes very fine levels of detail and can detect items of almost any size, confirming the presence or absence of items on the trays.

Detecting a Line of Adhesive on a Vehicle Door Panel

A VE Series Smart Camera, configured to use the bead tool, inspects each door panel for the presence and consistency of adhesive. The camera has a wide field of view and a 2 MP imager capable of detecting even slight inconsistencies in the amount of adhesive applied.

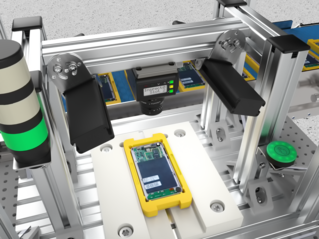

Fine Detail Inspection of Mobile Electronic Devices

Cell phones and other mobile electronics have densely populated components on their printed circuit boards. A VE Smart Camera is used to capture all the fine details and ensure that all components are present and placed correctly. Using a camera eliminates the risk of human error and prevents malfunctions and recalls.

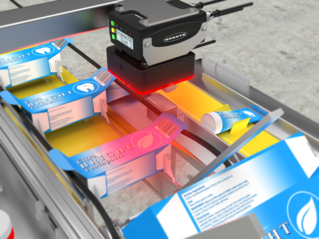

Verifying Product Logo on Paperboard Packaging

A VE Series Smart Camera inspects the product logo on each box before the tube of toothpaste is inserted. As a box enters the inspection area, it is detected by a sensor on the line and an output is sent to the trigger input on the camera, which captures an image of the region of interest (ROI). A red LED ring light powered by the camera enhances the contrast between the product logo and the surrounding packaging.

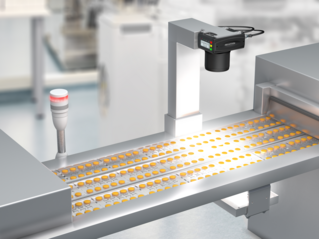

Inspecting Tablet Placement Quality in Blister Packs

A single VE Series Smart Camera, adjacent to the machine’s outfeed, inspects multiple rows of blister pack trays in a single inspection. The camera is installed approximately 36 cm over the production line and an LED backlight is installed 10 cm below the production line.

Videos

VE Series Smart Cameras: Versatile, Easy-to-Use

An introduction to VE Series Smart Cameras, a cost-effective, easy-to-use and easy-to-implement solution that solves a broad range of vision applications.

Basic Match Inspection Setup with VE Series Smart Cameras

Video tutorial demonstrating the ease of setting up a basic inspection for a VE Series Smart Camera using Vision Manager image processing software from Banner Engineering.

![Vision Manager Software for VE Series Smart Cameras [Video]](/content/dam/banner-engineering/projects/video-thumbnails/VE_Series_Video_Thumbnail-new.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

Vision Manager Software for VE Series Smart Cameras [Video]

Learn about the powerful capabilities and easy-to-use tools offered by Vision Manager, the free image processing software package from Banner Engineering for VE Series Smart Cameras.

VE Series Smart Cameras - User Interface Overview

Video tutorial for Vision Manager, the free, and easy-to-use image processing software package for VE Series Smart Cameras from Banner Engineering.

VE Series Smart Cameras - Emulator Overview

Video tutorial for the VE Emulator found in Banner's Vision Manager software for VE Series Smart Cameras.

-

VE200G1A

VE Series Smart Camera for Vision

Pixels: 752 x 480

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE202G1A

VE Series Smart Camera for Vision

Pixels: 1600 x 1200

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE205G1A

VE Series Smart Camera for Vision

Pixels: 2592 x 2048

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE201G1A

VE Series Smart Camera for Vision

Pixels: 1280 x 1024

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE202G1C

VE Series Smart Camera with Vision + ID

Pixels: 1600 x 1200

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE205G1B

VE Series Smart Camera with ID Only

Pixels: 2592 x 2048

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE200G1C

VE Series Smart Camera with Vision + ID

Pixels: 752 x 480

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE202G2A

VE Series Smart Camera

Pixels: 1600 x 1200

I/O: 6 Optically Isolated

4-pin D-Code Ethernet Connector

Requires 1 MQDC2S-12XX and 1 STP-M12D-4__ Cable; and 1 C-mount Lens -

VE200G1B

VE Series Smart Camera with ID Only

Pixels: 752 x 480

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE201G1B

VE Series Smart Camera with ID Only

Pixels: 1280 x 1024

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE201G1C

VE Series Smart Camera with Vision + ID

Pixels: 1280 x 1024

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE202G1B

VE Series Smart Camera with ID Only

Pixels: 1600 x 1200

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens -

VE205G1C

VE Series Smart Camera with Vision + ID

Pixels: 2592 x 2048

I/O: 6 Optically Isolated

Requires 1 MQDC2S-12XX and 1 STP-M12-8XX Cable; and 1 C-mount Lens