Remote I/O

Remote I/O Blocks from Banner help machine builders optimize control system design, performance, and space efficiency with their compact form factors, multiprotocol support, onboard programmability, and customization capability. Additionally, these products offer what you would expect from remote I/O blocks such as reduced wiring and costs associated with installation, integration, and diagnostics.

Optimize Control System Performance

Banner’s Remote I/O products optimize control system performance and simplify system design for machine builders and controls engineers. Typically, I/O blocks reduce wiring and feature onboard diagnostics LEDs, and they reduce the costs of installation, integration, and maintenance. Banner I/O Blocks do all of this, but they also provide additional benefits. These include greater flexibility for control system design, improved control system performance, multi-protocol support, compact designs that reduce I/O clutter and save space within your machine or cabinet, and options for customization.

Versatile Housing and I/O Options

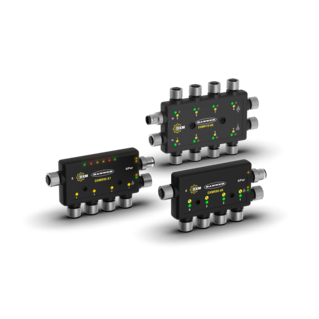

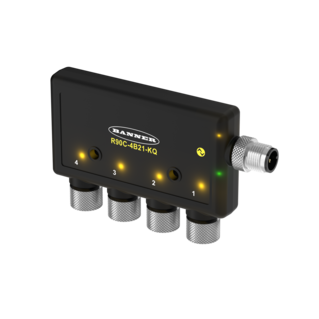

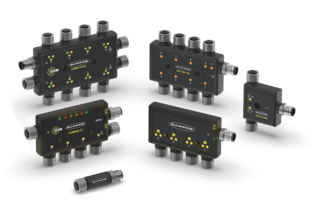

Banner I/O Blocks feature 1-port, 2-port, 4-port, and 8-port designs, so you can select the right number of inputs and outputs for a given location or reserve spare ports for future modifications. These devices offer discrete and analog I/O and IO-Link or Modbus connectivity.

The shapes and sizes of Banner I/O Blocks represent a unique innovation for the industry. They are lightweight for installation in payload-sensitive applications, and multi-port blocks are stackable for a reduced footprint.

Advanced Metrics and Simplified Programming

Banner I/O Blocks streamline PLC or HMI programming through intelligent features that enrich basic discrete signals. This enables the blocks to monitor a wide range of metrics from discrete signals, such as count, durations of input pulses, events per minute, and counts per minute, at speeds up to 5000 Hz. This capability also provides configuration options for port mirroring—to route an input state to any outputs on the same block, for example—and delay modes for each port, including on/off delays, one-shots, pulse stretchers, and more. Specific I/O Blocks also include DXM functionality to improve performance by shifting system control logic away from PLCs. These also allow you to write programs in ScriptBasic or use Banner software to simplify adding action rules, math functions, and other commands.

Optimize Control System Design through Customization

Banner can help reduce the number of components in your control system. Consolidate functionality from multiple parts into one I/O block via our pin-level customization capability. If you’ve already created a custom program or configuration for your device, Banner can pre-load that from the factory. In addition, we can print custom labeling for branding or user guidance on I/O blocks. Each standard M12 port can be replaced with a cable or an alternate connector. To further optimize high-volume machine-build processes, we can create custom kits of all required I/O components for your machines, including I/O blocks, brackets, connectivity, and more.

Banner’s Remote I/O products not only simplify your control systems but also elevate their performance, reduce costs, and enhance customization possibilities, ensuring a cutting-edge solution for diverse industrial applications.