Motors, Fans & Pumps Whitepaper

Preventing failure of rotating assets with predictive maintenance using condition monitoring solutions.

Predictive maintenance is an automated approach to monitoring and diagnosing assets, which can identify and track gradual performance decline before traditional maintenance methods can spot it. Using condition monitoring equipment, this approach leverages data, analytics, and machine learning to optimize the performance and longevity of industrial equipment.

Predictive maintenance systems are replacing preventive maintenance for good reason. Rather than staff running routine checks of well-functioning equipment, predictive maintenance uses a condition monitoring system to track the following measurements from each production asset:

The system then charts performance trends, and it notifies the maintenance team of any issues, when the asset is still in good serviceable condition, increasing equipment life and productivity. Condition monitoring systems also notify the maintenance team of any sudden changes in performance and send out warnings or alerts to allow quick intervention.

With predictive maintenance, technicians focus on needed repairs, rather than routine checks, reducing labor costs. The data collected by a condition monitoring system lets plant managers make educated decisions rather than gut decisions about production capacity and new equipment purchases.

Condition Monitoring for predictive and preventive maintenance for manufacturing equipment provides real-time data to ensure your equipment is running at optimal performance.

A vibration and temperature sensor is continually monitoring airport baggage conveyor motors and components to reduce failure and downtime.

Does your maintenance strategy include spending time on unnecessary tasks? The average plant has vast numbers of production assets. If your technicians walk “routes,” checking healthy equipment for problems, their time could be better spent. Technicians’ time is more valuable when they are maintaining or repairing ailing equipment, not searching for potential problems to fix. Condition monitoring systems allow facilities to automate the process of monitoring their assets’ performance in the following ways:

A vibration and temperature sensor monitors a bearing, providing teams with real-time insight about the health of the equipment and the overall need for maintenance.

When technicians perform preventive maintenance based on time intervals rather than equipment condition, it’s analogous to the traditional method of changing your car’s oil every 3,000 miles, which is a “preventive” method of maintenance. Newer cars notify the driver when an oil change is needed, based on driving habits, temperatures, and other usage, which is a “predictive” maintenance method. No time or money is spent on unnecessary maintenance, which can generate excessive costs. Likewise, with predictive maintenance, manufacturing plants don’t waste money or labor on parts that are performing perfectly well.

Monitoring the health of air compressors ensures maintenance is performed when needed, helping to extend the life of these critical assets.

Besides saving money by avoiding unnecessary checks and unnecessary maintenance, a predictive maintenance solution also extends the equipment’s life because maintenance is optimized.

With a traditional preventive maintenance strategy that employes routine equipment checks, there’s often enough time between maintenance intervals for an asset to fail. A condition monitoring system used with a predictive maintenance solution will reveal declining asset performance at the earliest stage, ensuring there’s plenty of time for proper maintenance to keep the asset healthy. And of course optimizing maintenance ensures plants avoid catastrophic failures, which may prematurely end the life of the asset.

Production output can be measured in revenue per hour, so as equipment goes down, overall productivity drops, along with revenue.

Unnecessary maintenance may require that machines are taken offline, thereby reducing efficiency and overall productivity. Besides downtime for minor maintenance, plants with assets not optimally maintained are at a higher risk of critical asset failure. When this occurs, the downstream processes become starved.

In order to avoid this and to reach peak output, machines must be performing at maximum efficiency. Predictive maintenance solutions ensure equipment is functioning in optimal condition so uptime and plant throughput will be maximized.

Monitoring vibration on a conveyor motor alerts maintenance teams to potential issues, allowing service to be performed during scheduled downtime, allowing productivity to remain high.

With a predictive maintenance strategy, condition monitoring data allows management to estimate total plant capacity, identify the occurrence of failures, and determine the probability of them occurring again. If analysis reveals too much risk with your current equipment, you can confidently make a data-based decision to upgrade existing equipment or make an entirely new equipment purchase. Staffing decisions can also be made based on real-time performance of equipment, which can help you improve your allocation of labor.

Five Steps to Implementing a Predictive Maintenance Program

Preventing failure of rotating assets with predictive maintenance using condition monitoring solutions.

Practical solutions and valuable insights on how to prevent rotating asset failure in rubber and other product manufacturing plants, where replacement lead times can be long.

If you are looking for a plug-and-play condition monitoring solution that does not require any programming to setup, start with our Asset Monitoring Gateway Solutions. If you would rather select from a variety of sensors, gateways, and develop a custom software configuration on your own, check out our Vibration Solutions. To learn more about how you can visualize your assets remotely from anywhere visit Banner Cloud Data Services.

Discover the power of Banner Engineering's products with a personalized virtual or on-site demonstration. Explore key features, expanded application examples, and get expert answers to your technical questions. Experience cost-effective, reliable solutions designed to increase uptime and enhance productivity. Contact us today at 1-888-3-SENSOR (736767) or by chat below and see for yourself why Banner Engineering is the trusted choice.

Predictive maintenance starts with sensors to measure your assets most critical parameters, such as:

Banner offers wired and wireless communication options to connect all measurement points and convert them to a common communications protocol. Implementing a wired communication option offers fast sensor sample rates to get a more detailed look at machine health over time, whereas a wireless option lets you deploy sensors without routing cables over long distances.

Getting your data to the cloud is easy. Via a wired or wireless node, connect your sensor to a controller with modem. Banner’s Snap Signal product line offers a portfolio of hardware, starting at the sensor level to get machine health information from production machines, and sent it to the cloud via a Banner gateway for easy monitoring.

Banner’s Cloud Data Services (CDS) software is a web-based platform that allows users to access, store, protect, and export critical data that’s collected by wired and wireless sensors. CDS offers a dashboard that allows maintenance staff and plant management to view data from the assets being measured.

With Banner CDS, you own the data. You can securely connect to the cloud and, if needed, export your data to a third party. You retain ownership of the data and have full control over it. Pilot programs can be implemented easily to prove out concepts and value quickly, before scaling the solution.

Day-1 value: Installing a Banner factory predictive maintenance system is simple, allowing operations to get started in minutes, not days, weeks or months.

With unplanned downtime, there’s lost production revenue, idled labor, equipment repair or replacement costs, excess inventory, and possibly quality issues. There are also harder-to-quantify costs that should still be considered. These include penalty costs for missing deadlines, lost opportunity costs of accepting new orders, and overhead costs that continue to accrue even while production is halted.

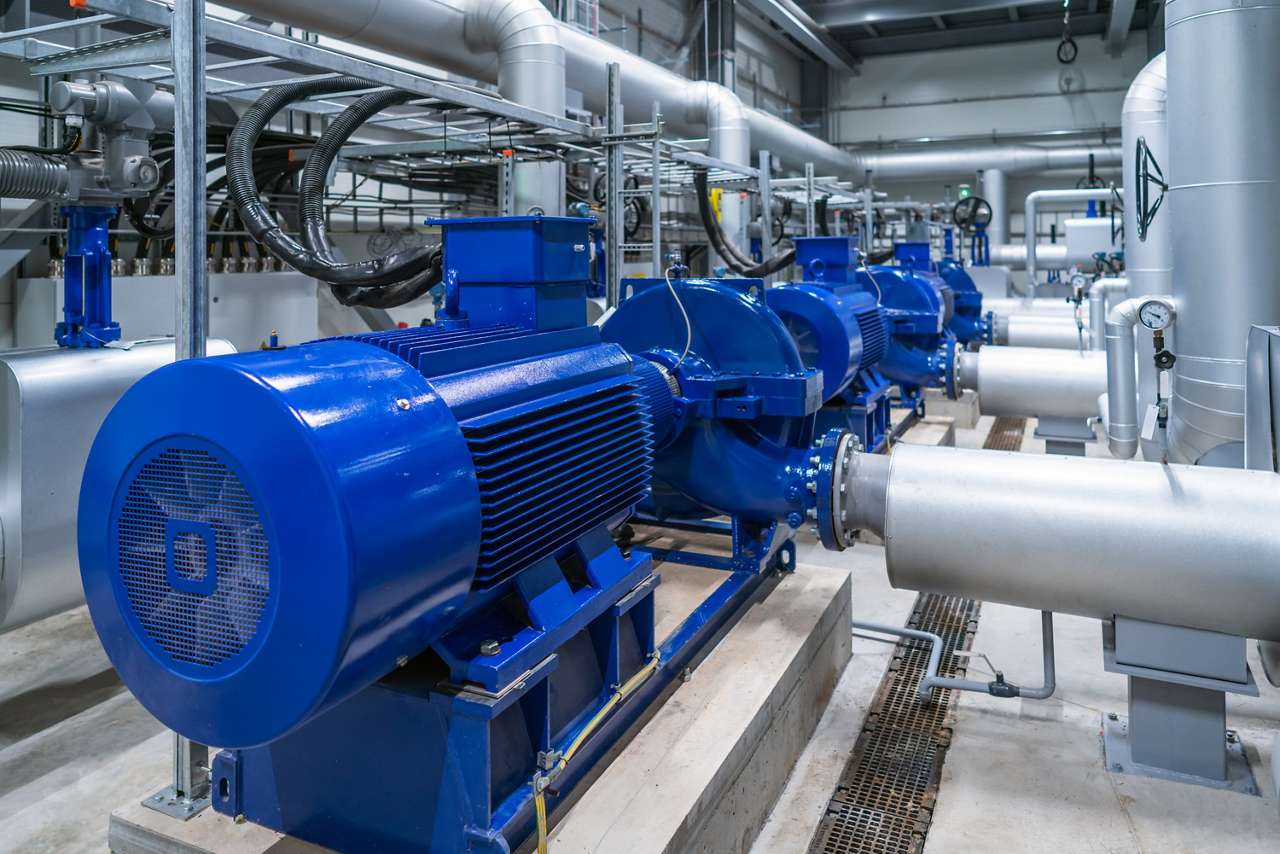

Predictive maintenance is a strategy that uses condition monitoring and analysis equipment to automate performance checks of production assets. The process optimizes maintenance intervention so technicians’ time can be spent on high-value repairs and upkeep, instead of walking “routes” and checking machines that don’t need attention. An example of predictive maintenance is using vibration monitoring data to analyze the performance of a rotating machine, such as a pump or motor, and predict when maintenance is required based on changes in the vibration patterns.

By tracking equipment performance data trends and predicting when maintenance is required, you can increase equipment uptime, reduce maintenance costs, and avoid unplanned downtime.

Data used for predictive maintenance comes from vibration sensors, temperature sensors, pressure sensors, and other equipment. Vibration and temperature sensors can detect issues such as bearing wear and equipment component misalignment, while temperature sensors can help detect overheating or cooling issues. Pressure sensors can detect improper pressure levels in hydraulic or pneumatic systems.

IIoT, or the Industrial Internet of Things, has unlocked the ability to implement predictive maintenance on a large scale. This is because a wealth of information from various sensors and other points can now be made available. And getting this data up to the cloud for monitoring has never been easier. Predictive maintenance is arguably the "killer app" for IIoT.

Implementing a predictive maintenance pilot is not complex. You will need the following:

1. Sensors to collect machine health data.

2. A gateway to connect sensors to the cloud.

3. A web dashboard where data can be viewed from anywhere.

Once a pilot proves the process of adding a condition monitoring system, for predictive maintenance, the program can be easily scaled. However, preventative maintenance may never go away entirely; it depends on the cost/benefit equation, which is unique to every business. In certain instances, businesses may choose to run some less critical assets until they breakdown.

Predictive maintenance can be implemented and scaled across an organization by developing a roll-out plan that prioritizes the highest-value production machinery. There are no predefined thresholds for prioritizing your assets. It depends on your business needs, level of urgency, and budget. Following is a list of considerations to help you determine each asset’s relative value and whether it makes sense to monitor it as part of a predictive maintenance program:

Developing a prioritized roll-out plan will ensure that the assets most important to production will get attention first and that predictive maintenance is implemented consistently across the organization.

A power company might use predictive maintenance to monitor a gas turbine, so technicians can plan the optimal time to perform maintenance. Or a manufacturer might use predictive maintenance to set benchmarks for asset performance, so alerts and warnings can be set up to notify the maintenance team that an asset needs immediate intervention.

For a specific example, we can look at a tire manufacturer that uses a massive gearbox to transmit power from a motor to a mixer for liquid rubber. These gearboxes are critical to their operation, yet if one experiences catastrophic failure, there is a two-year lead time to secure a replacement. Because of this need for a healthy gearbox, some tire manufacturers choose to employ ten or more vibration sensors on important rotating components such as input shafts, output shafts, couplings, bearings, gears, and others. If there is a problem with a component, such as a bearing, the maintenance team is notified so it can perform maintenance before serious problems develop.