-

Industries

-

Packaging

-

End of Line Packaging

Packaging: End of Line Packaging

End of the Line Packaging Solutions

From regulating the flow of packed cases as they are conveyed to the palletizer to protecting personnel and equipment at machine access points, Banner products solve end of the line packaging problems.

Our expertise in advanced optics, LED, laser, and photoelectric circuits allow us to offer sensors that easily detect clear targets and reflective packaging and feature On/Off timing delays to regulate package flow. We have the most comprehensive collection of safety products in the industry, including heavy-duty safety light curtains designed to withstand mechanical impact and expandable safety controllers that simplify and centralize safety device setup and management. Rely on our rich industry experience and rich portfolio of sensors, safety control, LED lighting and indication products to improve your packaging processes and address all your machine safeguarding requirements.

Applications

Barcode Reading

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present. Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

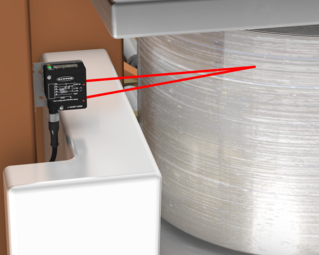

Plastic Roll Diameter Measurement

Banner’s LE550 is factory configured with a range of 100 to 1000 mm and can start measuring immediately. If the range needs to be adjusted, the laser sensor has an intuitive user interface with a two-line, eight-character display, making it easy to automatically or manually adjust settings. The LE550 provides repeatability and accuracy across challenging targets, from metal to black rubber, allows for reliable measurement of the shrink wrap.

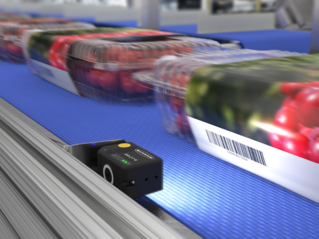

Tracking Products through Packaging

Barcodes used to track packaged produce through the supply chain contain important product information that must be verified at multiple points during packaging. An ABR 3000 barcode reader ensures that the barcode on each package is present and correct.

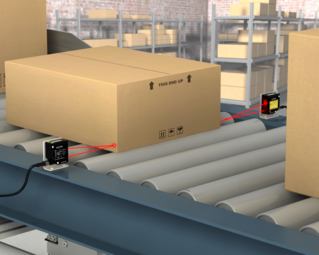

Barcode Confirmation on Pallet

Shipping containers are often labeled with barcodes in order to more easily identify which product is present and ready to be shipped. A sensing solution needs to be present to confirm that the final, shrink-wrapped product is labeled correctly and matches the content inside.

Enunciation of Safety Conditions with Visual Indication

In order to maintain an efficient manufacturing line in the beverage industry, immediate notification of any safety issues is fundamental. Using visual and audible indication to identify safety concerns helps workers quickly find and fix the errors – returning the system to its normal operating state in a timely fashion.

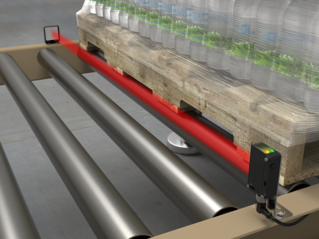

Leading Edge Detection

Sensors detect the leading edge of pallets, polybags, blister packs, envelopes, tubes, and a wide range of difficult to detect targets.

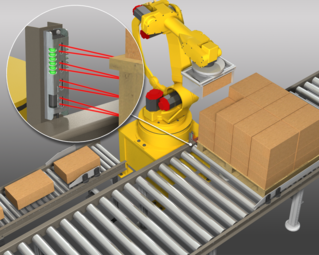

Robotic Palletizer Safeguarding

Banner’s XS26-2 is a flexible, easy-to-use safety controller with an intuitive programming environment, with the capacity to handle current machine processes and the flexibility to add up to eight I/O expansion modules as machine automation grows or changes. A broad spectrum of safety devices are supported, allowing for complex applications to be configured and downloaded to the controller in a minimal amount of time for efficient machine commissioning.

Reading Multiple 1D and 2D Barcodes

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

Carton Profiling

Cartons moving on a conveyor pass between two LE550 laser sensors, measuring the width in order to sort cartons properly. The LE550 sensors are an economic solution for carton profiling. The analog output sends a signal to the PLC to deliver the carton to the correct storage location. Banner’s LE550 provides repeatability and accuracy while measuring the height, length and width of cartons. The laser sensors have an intuitive user interface, making it easy to adjust settings.

Featured Products

Q4X Series Rugged Laser Distance Sensor

Rugged Q4X laser distance sensor solves many challenging applications and comes in a rugged IP69K rating with FDA food grade stainless steel housing.

XS26 Series Expandable Safety Controllers

The XS26 is expandable for complex safety applications where 3 or more safety relays are typically used. Five different communication protocols are available, including EtherCAT (via communication module). Supports up to 154 safe inputs and up to 68 safe outputs using expansion modules.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

SC26 Series Safety Controllers

Flexible safety controller for machines that typically use 3 safety relays. Supports 26 inputs and 2 dual channel outputs with 0.5 amps each.

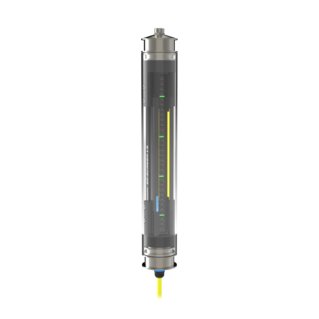

LE Series 1 m Range Laser Displacement Sensor

LE's measurement accuracy, ready to measure distances of 100 to 1000 mm, is suitable for controlling, sorting, and inspection tasks in quality control.

30 mm Mount Emergency Stop Buttons

Patented 30 mm mounting base enables easy installation and hookup with no assembly, individual wiring or additional enclosure required.

30mm Mount Emergency Stop Buttons

Illuminated button for easy identification of which e-stop has been activated. 30 mm mounting base for easy installation and hookup with no assembly.

WLS28-2 Versatile, All-Purpose LED Strip Light

28 mm profile compact LED light for a variety of industrial applications. Available with motion sensors, various lenses & windows for max flexibility.

LS Series Heavy-Duty Type 4 Safety Light Curtains

Intuitive, easy-to-use, feature rich models available in 14, 23 & 40 mm resolutions and up to 1820 mm (6 ft) lengths with no dead zone. Highly visible alignment indicators and intuitive diagnostics simplify set-up and provide machine builders with additional value to meet a wide range of needs.

LS Series Kits

Banner’s LS Series light curtains are intuitive, easy-to-use machine guarding devices built to withstand challenging manufacturing and packaging environments.

LS Series Kits

Banner’s LS Series light curtains are intuitive, easy-to-use machine guarding devices built to withstand challenging manufacturing and packaging environments.

TL70 Core Series 70mm Modular Tower Lights

Big, bright tower lights come preassembled or as modular segments for customized indication. Lights are gray when off to eliminate false indication.

TL70 with Audible Indicator

Segments for the TL70 Tower Light are available in adjustable audible modules. Modules offer tremendous flexibility and can be customized as needed.

Q60 Series 2 m Range Adjustable-Field Sensor

A long-range sensor with a sharp cut off and high excess gain to detect dark targets, and a laser model to detect thin targets at maximum range.

Success Stories

Pallet Detection for Conveyance Equipment

A leading manufacturer of conveying equipment designs and builds high-quality, low-cost conveyance solutions. The pallet equipment they develop is expected to reliably convey, palletize and depalletize thousands of pallets and unit loads annually. This equipment must be able to sense a wide range of different pallet types and sizes to ensure the proper packing and unpacking of pallets and avoid line slow-downs, pallet crashes and collapses.

Combined Inspections Used to Meet Quality Standards

Bottles incorrectly packed into bliss trays for sale in club stores did not properly display product labels and had to be returned to the company.

Detecting Various Registration Marks

Hamer, LLC is a Minnesota-based manufacturer of automated packaging equipment for a wide variety of applications and world-wide customers. From pet food to pellet fuels, Hamer machinery packages products in a variety of weights and sizes at speeds up to 60 bags per minute. A vital component of Hamer’s equipment is registration mark sensing—the ability to detect marks on packaging as it passes at high speeds. When a mark is detected, the equipment cuts the packaging at the designated location, eliminating waste and ensuring each bag is consistent.

Simplifying Safety Feature Management

Algus Packaging Inc. is a leader in the heat seal and thermoform packaging industry. They design, develop and manufacture high-performance sealing machines, thermoformed packaging and offer full service contract packaging. The machinery and services offered by Algus provide their customers with the ability to change and grow as business needs dictate, now and in the future.

Accurate Label Inspection

The company was experiencing several quality control issues—bottles were coming off the line with missing, skewed and double labels. As a result, the customer was scrapping over 2,000 bottles a month, a process which requires them to cut out the mislabeled portion of the bottles and re-grind the plastic for reuse. Further, the labeling errors began prompting serious customer complaints. To avoid scrapping additional bottles and losing loyal customers, the company came to Banner for a label inspection solution.

Preventing Shipping Errors at a Large Distribution Center

The customer was looking for a single-output solution that senses packages quickly, is easy to install and maintain, and was affordable enough to buy in bulk quantities if needed.

Shrink Sleeve Labeling at High Speeds

A leading manufacturer of labeling equipment offers high-speed shrink sleeve label applicators designed to process 800 bottles per minute. To maximize the machine’s performance potential, the company wanted to install sensors capable of consistent detection and output for high-speed bottling.