Shrink Sleeve Labeler Solutions for Beverage Packaging

Shrink sleeves are commonly used in beverage packaging as they easily conform to unique object shapes and provide 360 degree coverage for maximum branding opportunities. A high-speed shrink sleeve machine applies labels onto a wide variety of bottles and jars as they pass by quickly on a conveyor belt.

Shrink label machines have become very popular in recent years due to the low cost of the shrink material as well as the powerful visuals that these types of labels provide. The circular form of shrink sleeves creates opportunities for eye catching 360° graphics around the entire container. This is important because it increases visibility on the shelf and are more durable than other labeling options.

Shrink sleeve machines are a very crucial step on a beverage filling line because it is an area that sees very frequent changeovers, has a high risk of jamming or slowing down production speeds, and must perform well in a fast paced environment.

Introducing a shrink sleeve machine into the beverage industry creates some unique challenges. Most beverage lines work at very high speeds in order to maximize throughput and are subjected to frequent high-pressure washdowns. This type of environment requires automation solutions that have quick response time and that are made of rugged material that can withstand water. Solutions also need to be incredibly versatile because of the wide variety of sleeve labels that get used on beverage containers.

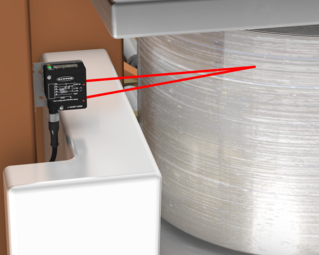

Banner Engineering’s automation and quality control solutions can be integrated into the applicator, conveyor, and heat tunnel of a shrink sleeve label applicator. These include label roll diameter monitoring, container detection, registration mark detection, and label presence and accuracy verification. We offer many sensors, lighting options, and safety solutions that are rated IP67 or higher, are easily adaptable, and respond quickly and accurately.