Automotive Success Stories

-

Temperature Sensor Detects Defrost Wires

Temperature Sensor Detects Defrost Wires

An automotive manufacturer was rejecting a supplier’s shipment of rear window assemblies due to faulty defroster grids. The supplier’s existing test procedure measured current draw across the entire heating system to detect an overall failure, but it could not detect the subtle impact of a single heating wire being broken. The window supplier partnered with a Michigan-based machine automation company to create a better test fixture—one that can verify each defrost wire heats to specification prior to shipping.

-

Status Indication on Driverless Vehicles

Status Indication on Driverless Vehicles

The K50L domed 50 mm indicator light works well for status indication on autonomous shuttle buses. The buses operate on short distances in outdoor environments that exposed the bus technology to a variety of weather conditions. The rugged K50L indicators are rated IP67 and IP69K to withstand water ingress in the harsh environment.

-

UV Barcodes for Traceability

UV Barcodes for Traceability

Before shipping to the brand assembler, a supplier of auto visors needs to verify that Data Matrix UV barcodes have been printed on each visor’s safety label. The customer turned to Banner to read invisible 2D Data Matrix barcode and send data via Ethernet IP to a PLC for traceability/error proofing.

-

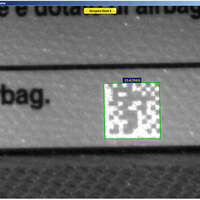

Vision Sensor to Read QR Codes

Vision Sensor to Read QR Codes

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

Operator Guidance Solution

Operator Guidance Solution

A Henshaw customer manufactures drivetrain and powertrain systems for the automotive industry. The company had experienced productivity losses due to errors in the assembly of transmission valve bodies. Henshaw was tasked with developing a system that would reduce errors and improve the assembly process.

-

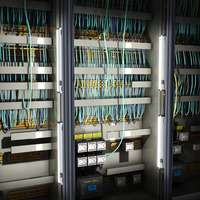

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

Operators access machine systems through the control cabinet and need Intense illumination of the cabinet facilitates for maintenance and management.

-

Superior Light Distribution with LEDs

Superior Light Distribution with LEDs

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

Inspecting Small Connectors

Inspecting Small Connectors

An automotive supply company makes a range of vehicle systems. Their seating systems combine structure and design with features that enhance comfort and safety. Weight sensors installed on the underside of the seats work in coordination with vehicle safety systems to determine the size and position of a seat occupant. These factors affect how or if airbags will be deployed in the event of an accident.

-

Sensors to Measure Movement Range

Sensors to Measure Movement Range

During assembly, inspections are conducted to measure seat height adjustment, forward and rearward movement, and upright and recline motion.

-

Run Bar Provides Operator Guidance

Run Bar Provides Operator Guidance

A leading machine manufacturer builds workstations designed for accurate, timely and cost-effective battery cell assembly. A value added component of the workstations is an operator guidance device that does three jobs: enables assembly processes to start and stop, indicates parts to be picked and installed, and completely stops line operation if emergencies occur. When it became too costly for the OEM to construct and mount these devices themselves, they turned to Banner to craft an all-inclusive solution. To honor the time line requirements of their customer—a major tier two battery supplier—the OEM needed the solution in eight weeks.

-

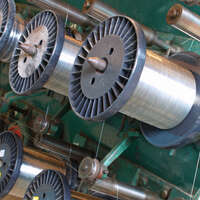

Zero Defect Standard on Industrial Winder

Zero Defect Standard on Industrial Winder

A successful manufacturer of specialty industrial yarns makes fiberglass and glass thread products for applications in the automotive, aerospace, military and composite materials industries. To help maintain their high standards and minimize costly product returns, they established a goal of zero product defects. To meet this goal, the company needed an automated thread inspection system.

-

Shopping Center Directs Vehicles to Available Parking

Shopping Center Directs Vehicles to Available Parking

A large retail shopping center reduced vehicle congestion, customer aggravation and drive-offs using wireless sensors.

-

Detecting Parts Ejected from Die

Detecting Parts Ejected from Die

In the manufacturer's facility, operators manually insert and remove metal parts from the die press. When complete, the parts are sent into a bin via a metal chute. In order to prevent die crash (having double parts in the press at once) the customer needed a sensor that could detect various parts on the chute and send a signal to the control system, indicating that the press is free and allowing the operator to perform another stroke. The solution needed to be installed without cutting slots in the chute sides or mounting sensors at the end of the chute, which could create catch points for traveling parts.

-

Communication in a Busy Manufacturing Site

Communication in a Busy Manufacturing Site

As more components pass through the oven, keeping pace with the flow of items to be unloaded becomes increasingly difficult. Congestion in the sortation area builds. Items can easily be misdirected or even damaged. A pause in the flow of parts allows the unloading operator to correct mistakes and clear a pickup station. However, the distance between the unloading and loading areas as well as ambient interference from surrounding machinery complicates communication between operators.