Automotive: Vehicle Components Solutions

-

Easy Panels with Multicolor Indicators and Touch Buttons

Easy Panels with Multicolor Indicators and Touch Buttons

S22 Pro Series touch buttons and indicators simplify control panel design and improve operator experience and performance. Pro Editor software expands the built-in display capabilities available with the S22 Pro Series, enabling custom displays.

-

Monitor Hydraulic Power Units

Monitor Hydraulic Power Units

Easily monitor the pressure, current, oil temperature, and motor vibration/temperature of hydraulic power units and other hydraulic machinery. Snap Signal products connect sensors of various types and convert their signals to Modbus data for real-time condition monitoring.

-

Manual Load Weld Cell

Manual Load Weld Cell

Banner’s EZ-SCREEN® series safety light curtain system is a well established solution for the harsh requirements of welding equipment. With the ability to cascade (series connect) multiple segments together, configurations such as this horizontal/ vertical pair are easily implemented with standard hardware (no master/slave models).

-

UV Barcodes for Traceability

UV Barcodes for Traceability

Before shipping to the brand assembler, a supplier of auto visors needs to verify that Data Matrix UV barcodes have been printed on each visor’s safety label. The customer turned to Banner to read invisible 2D Data Matrix barcode and send data via Ethernet IP to a PLC for traceability/error proofing.

-

Vision Sensor to Read QR Codes

Vision Sensor to Read QR Codes

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

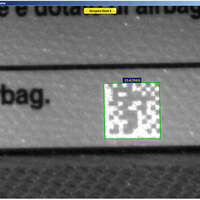

Reading DPM Codes on Automotive Components

Reading DPM Codes on Automotive Components

Direct part mark (DPM) codes can be small, complex, and difficult to distinguish from the material they are etched into. The ABR 7000 barcode reader is available in models specifically designed to solve challenging low-contrast and DPM applications like this.

-

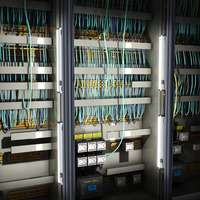

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

Operators access machine systems through the control cabinet and need Intense illumination of the cabinet facilitates for maintenance and management.

-

Superior Light Distribution with LEDs

Superior Light Distribution with LEDs

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

High-Quality LED Lighting for Conveyor Illumination

High-Quality LED Lighting for Conveyor Illumination

Finding a high-intensity, ultra-bright lighting solution for manufacturing can be challenging. Since multiple lights are required to properly illuminate areas on a conveyor, a simple mounting option to connect lights together is needed.

-

Inspecting Small Connectors

Inspecting Small Connectors

An automotive supply company makes a range of vehicle systems. Their seating systems combine structure and design with features that enhance comfort and safety. Weight sensors installed on the underside of the seats work in coordination with vehicle safety systems to determine the size and position of a seat occupant. These factors affect how or if airbags will be deployed in the event of an accident.

-

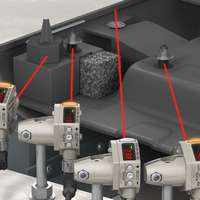

Sensors to Measure Movement Range

Sensors to Measure Movement Range

During assembly, inspections are conducted to measure seat height adjustment, forward and rearward movement, and upright and recline motion.

-

Tire Production: Loop Control for Shiny Black Tread Rubber

Tire Production: Loop Control for Shiny Black Tread Rubber

Loops must be closely monitored and machine speed adjusted to maintain proper tension on the material.

-

Ensuring Part Presence and Position on Car Doors from Afar

Ensuring Part Presence and Position on Car Doors from Afar

High excess gain enables the sensor to detect items from an angle and it has very high accuracy, so even slight variations in target position will be detected.

-

Detecting Black Parts on Black Door Panel

Detecting Black Parts on Black Door Panel

Since door panels are often dark colors such as black or gray, and the foam used to eliminate rattles and provide stiffness is generally black, it can be difficult for standard sensors to differentiate between foam presence and absence due to poor contrast.

-

Multiple Point Inspection on Stamped Metal Parts

Multiple Point Inspection on Stamped Metal Parts

To verify the expected number of holes exists on a small metal part, the iVu Plus TG Image Sensor with Multipoint Inspections can be configured for multiple regions of interest (ROIs) to ensure holes exist and were punched in the correct place. When set up for area inspection, the iVu will scan multiple points on the stamped part to verify the presence or absence of a feature or features of interest.

-

Automotive Fuse Box Inspection

Automotive Fuse Box Inspection

A PresencePLUS COLOR Pro vision sensor inspects color-coded fuses in a fuse box to verify that each fuse is in the correct location.

-

Part Color Inspection on a Vehicle Door Panel

Part Color Inspection on a Vehicle Door Panel

An iVu Color Sensor identifies RGB values of individual pieces of trim on vehicle door panels and communicates this information over an industrial Ethernet connection to a PLC.

-

Detecting Parts Ejected from Die

Detecting Parts Ejected from Die

In the manufacturer's facility, operators manually insert and remove metal parts from the die press. When complete, the parts are sent into a bin via a metal chute. In order to prevent die crash (having double parts in the press at once) the customer needed a sensor that could detect various parts on the chute and send a signal to the control system, indicating that the press is free and allowing the operator to perform another stroke. The solution needed to be installed without cutting slots in the chute sides or mounting sensors at the end of the chute, which could create catch points for traveling parts.

-

Bright Indication in Ambient Light

Bright Indication in Ambient Light

When a window is located directly behind a cabinet, extremely bright, long lasting LED indicator lights can provide highly visible indication throughout the day. Banner’s EZ-LIGHT K50 Beacon is perfect for many indication status applications, especially in this cabinet because the beacon is highly visible even during daylight and is extremely durable with long-lasting, energy-efficient LEDs.

-

Die Protection in Tire Manufacturing

Die Protection in Tire Manufacturing

The dies in tire presses suffer costly damage if the press tries to stamp the tread into an unstamped, or green, tire of the wrong size. To direct each tire to the correct press, Banner’s PresencePLUS P4 BCR 1.3 vision sensors sort green tires based on identifying information in the bar code printed on a label on the tire’s bead. In this application, the green tires moving on a conveyor pass below a fixture on which six BCR 1.3 vision sensors are mounted.

-

Bypass Capability on a Robotic Work Cell

Bypass Capability on a Robotic Work Cell

Using a 2 or 3-position OS80 key operated selector switch, the operator can bring the robot to a controlled stop, enter the cell, and then quickly resume operations once work in the cell is complete.