How to Use an Infrared Photoelectric Sensor for Water-Based Liquid Detection

Summary: One of the most difficult photoelectric applications involves sensing the presence or absence of clear fluids in clear bottles. Online weighing systems, low-contrast sensors and ultrasonic sensors are some methods used to detect water fill level but these methods are expensive, or not always very reliable. Learn more about how Banner’s QS30 H2O photoelectric sensor uses a unique optical property of water to reliably detect the presence or absence of water.

Q: Can the QS30 H20 photoelectric really sense clear water?

Yes. Thin layers of water are transparent to light in the visible spectrum, so photoelectric sensors with standard visible LEDs burn right through water and typically can't be used to detect the presence of water. However, the QS30 H2O uses an infrared LED at a wavelength of 1450 nm that is efficiently absorbed by water and many water-based liquids. If our eyes could see color in the infrared spectrum, at 1450 nm water would appear black.

Q: Will the sensor work on any liquid?

It will, as long as that liquid contains some amount of water. For example, it will work on juice, milk, hydrogen peroxide, rubbing alcohol, hair gel, soap or vinegar. Non water-based fluids may still block some of the emitted light because of factors like viscosity, or color. However, this sensor's key strength - its ability to detect water-based liquids using the 1450 nm wavelength - will not be useful in applications involving fluids such as vegetable oil or hydrocarbons. If you have any questions about whether or not the liquid in your application will be detected, you can always send a sample to our labs and we can test it.

Q: Can I use this sensor to detect solids with a high water content?

Yes, like any photoelectric sensor, the QS30 H2O can be used to detect solid objects even with no water content. If the target blocks enough of the emitted light beam, it will be detected.

Q: Can I use this sensor to tell what percentage of the liquid is water?

No, the sensor doesn’t output a reading on the percentage of water in the sample. It's used to detect the presence or absence of water, which for visible light photoelectric sensor can be a very low contrast and difficult application.

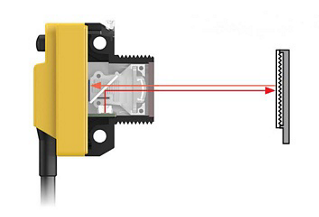

Image: Infrared photoelectric sensor detects water in plastic bottles.

Q: Does the color of the liquid matter?

Yes, the color of the liquid affects the total amount of light blocked by the fluid. You can expect a dark cola to block more light than clear water. A standard red LED sensor may work adequately in applications where you're detecting the presence of colored fluid. The QS30 H2O sensor provides additional contrast sensitivity by taking advantage of the 1450 nm absorption band of water.

Q: Does this sensor work only if my container is clear?

No, the sensor is designed with very high excess gain to burn through many containers commonly used in consumer goods. The light from the sensor’s emitter can burn through clear containers like glass or clear plastic easily. It can also burn through frosted glass bottles and some thin-walled plastic containers that are translucent but not totally opaque. The sensor doesn’t work on cardboard boxes or metal cans, and a label on the side of a bottle may also interfere with the beam. When working with non-clear containers, some testing and application support may be required to apply the sensor successfully.

Q: Why does the sensor burn through some materials and not others?

The QS30 H2O sensors are designed with the capacity for very high excess gain which allows the sensor to burn through some containers. But keep in mind that light interacts with different materials in different ways. Some materials easily transmit light and other materials block or absorb light. Thickness of the material has a direct impact on how much light passes through, and how much is blocked. Super high-power models of the QS30 H20 feature extra burn-through power to enable the detection of liquid contents in thicker containers.

Q: Does the shape of the container affect the sensor's ability to detect water?

Yes, shape and color of the container matter. Even labels can affect the ability of the sensor to burn through a container. Typically a container has fairly thin walls while the liquid contents are a thick layer – think of a plastic water bottle. With an empty container, the thin plastic walls block a small percentage of the light, but when the container is filled with water, the relatively thick layer of water absorbs a large percentage of the emitted light. This contrast between the empty and full container results in a high contrast sensing application because water absorbs the 1450 nm wavelength of light.

Q: What is the key to a successful application with this sensor?

The key to a successful application is determining if the QS30 H2O can burn through the empty container or not. If the sensor can burn through the empty container, generally the presence of any water-based fluid can be reliably detected.

Q: How can I control the excess gain on this sensor?

The opposed mode sensor pair comes in a high-gain and low-gain model. The total system gain can be adjusted with the use of apertures to block part of the beam, or the sensors can be slightly misaligned to reduce the amount of light reaching the receiver. The aperture also shapes the effective beam of the sensors. This will be useful when verifying a fill level in a container, or when working with containers smaller than the 13 mm diameter effective beam of the sensor.

Q: What sensor would I choose if I have translucent containers?

We recommend high-gain models when you require long working range or for frosted or translucent containers. The low-gain models are best in applications involving short working range or for use with clear containers and clear liquids.

Featured Products

Related Articles

How to Choose the Best Sensor for Clear Object Detection

Understand the differences between common sensor types in Clear Object Detection applications, such as ultrasonic vs. photoelectic retroreflective sensors.

3 Solutions for Semiconductor Wafer Presence Detection

See 3 solutions to reliably detect clear and reflective semiconductor wafers in a vacuum chamber.

Why Use Polarized Coaxial Optics For Detecting Clear Objects

Clear object detection sensors are sensitive to variations in light and benefit from polarized coaxial optical design to reduce false detection from reflected light.