Automated Quality Control

Identify Issues Early and Save Costs

Defects and errors in parts and components can negatively impact downstream processes, production efficiency, and product quality.

Consistent, reliable inspection of parts and components can help manufacturers identify potential issues early on in the manufacturing process, minimizing costly lost product and production time.

Banner’s expertise in a range of sensing technologies allows us to offer optimal quality control solutions for detecting defects, measuring components, monitoring tolerances, and verifying attributes.

Rugged, Reliable Sensors are Required

Automated quality control applications often involve inspecting challenging targets, such a clear and reflective targets, extremely dark targets against a dark background, multicolored targets with many color transitions, and targets moving at high speeds.

Depending on the application, the smallest errors can become critical failures further down the line, making precise inspection a must. In some applications, quality control inspections occur in extremely harsh environments, where sensing technology can be exposed to dust and dirt, high pressure washdown, machine vibration, and more.

Banner Engineering offers a range of rugged, reliable photoelectric, laser measurement, and vision sensors that improve your automated quality control processes--even in the most challenging applications. Keep reading to learn more, or contact us to discuss your specific application.

Reliably Inspect Every Target

Fast, reliable quality inspections are essential to ensuring consistent throughput without sacrificing quality.

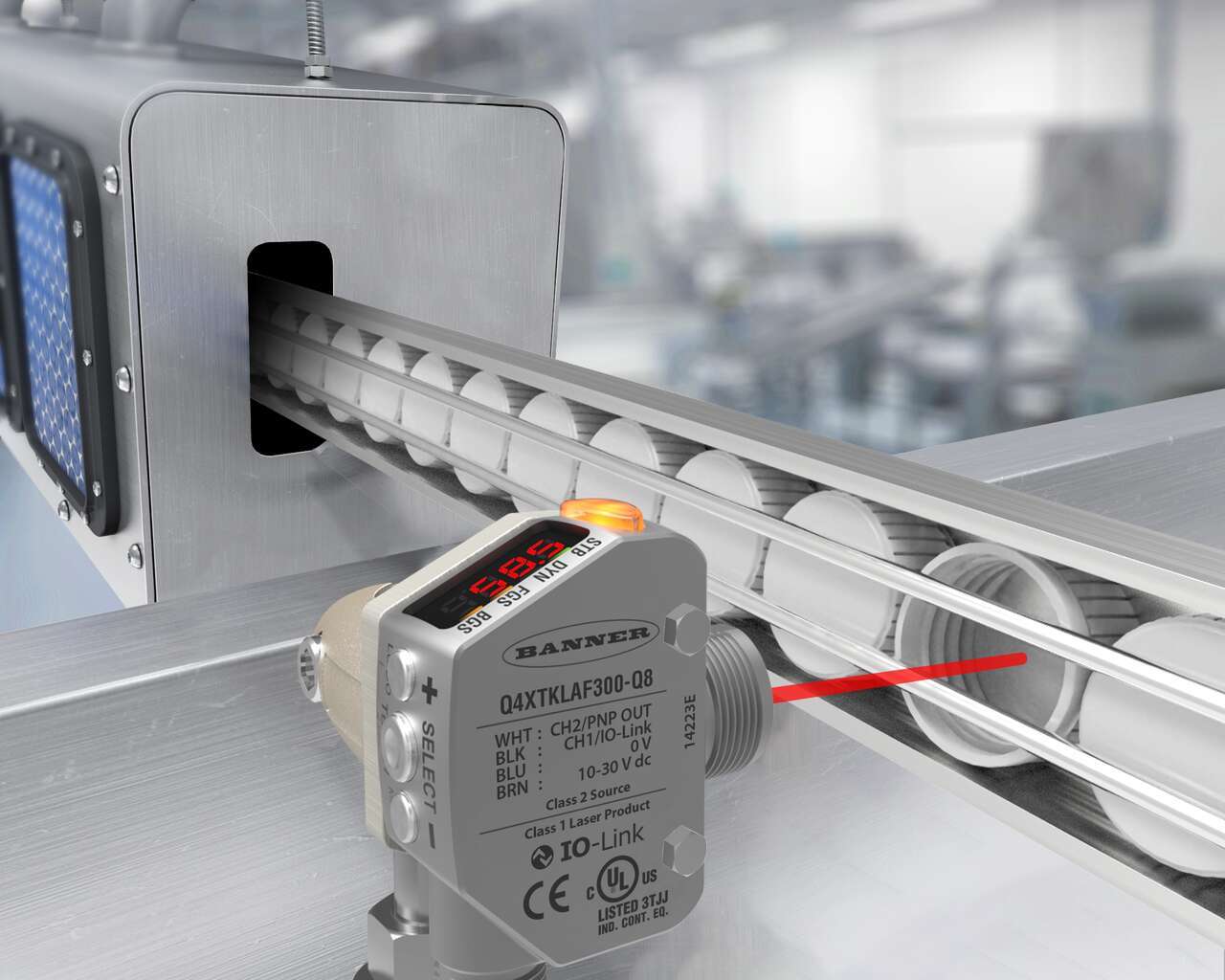

Thanks to advancements in laser measurement technology, sensors can now measure traditionally challenging targets (including clear, reflective, and low contrast targets). For example, the Q4X laser measurement sensor reliably inspects extremely dark targets on aginast an equally dark background.

in addition, thanks to dual mode which measures both distance and light intensity, smart laser measurement sensors from Banner can reliably inspect both distance-based and contrast-based conditions with a single device, which saves inventory costs.

Furthermore, with IO-Link communication, users can track sensor performance, identify trends in inspection results, and even predict when maintenance is needed so that simple problems like a dirty lens can be fixed prior to sensor failure.

Maintain Tight Tolerances

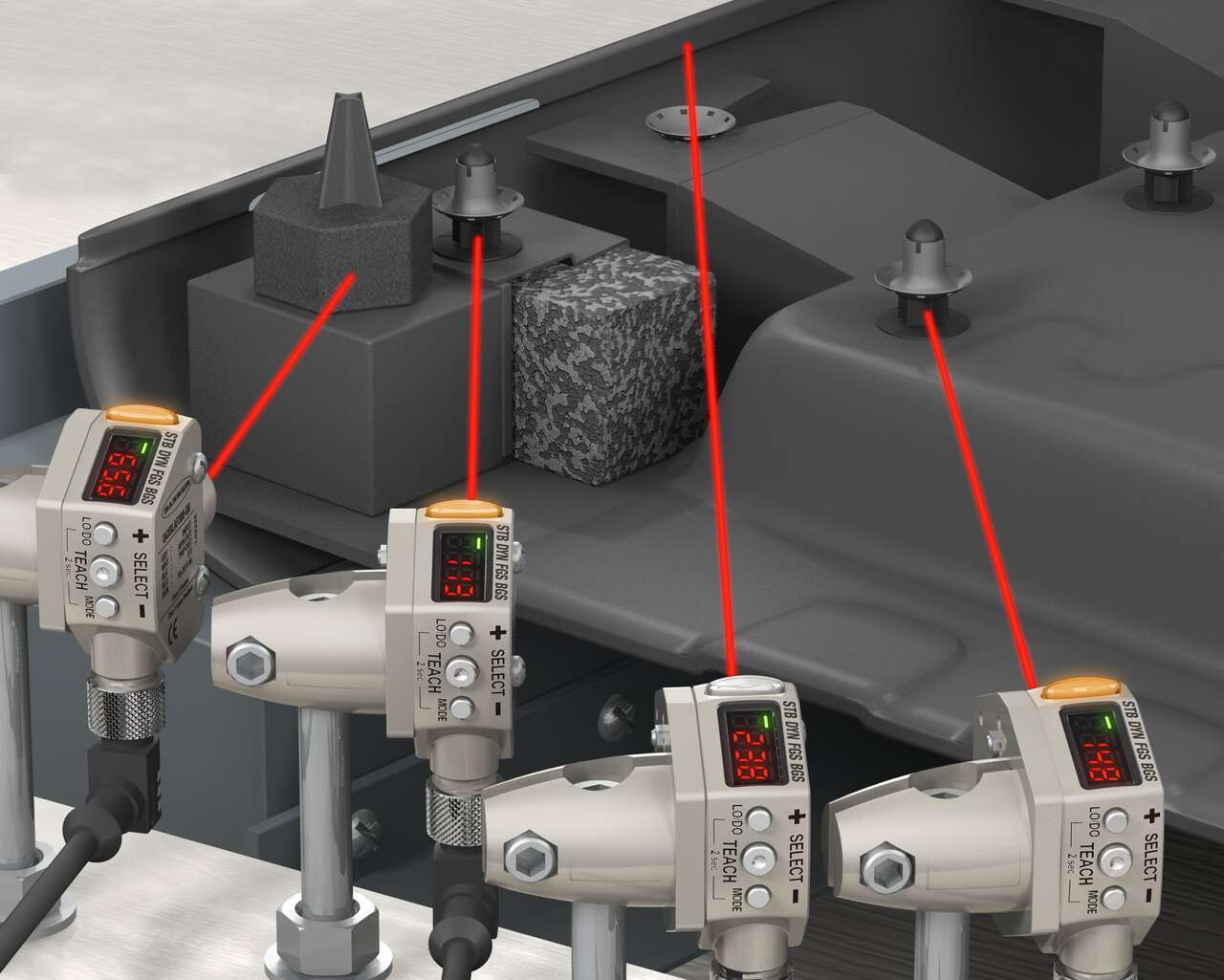

Quality control applications that require precise measurement can be some of the most challenging applications to solve. Very tight tolerance requirements demand a reliable solution that can measure parts in micrometers to detect the smallest variations in part size, thickness, orientation, placement, and more. Ensuring parts meet strict quality standards can help reduce problems downstream and reduce the risk of product recall due to imperfect parts.

Laser measurement sensors are a common solution for precise part inspections. However, real world conditions—including variations in target color and reflectivity, fluctuations in ambient temperature, and vibration from improper mounting—can make precise measurement challenging, even for laser sensors that perform well in perfect laboratory conditions.

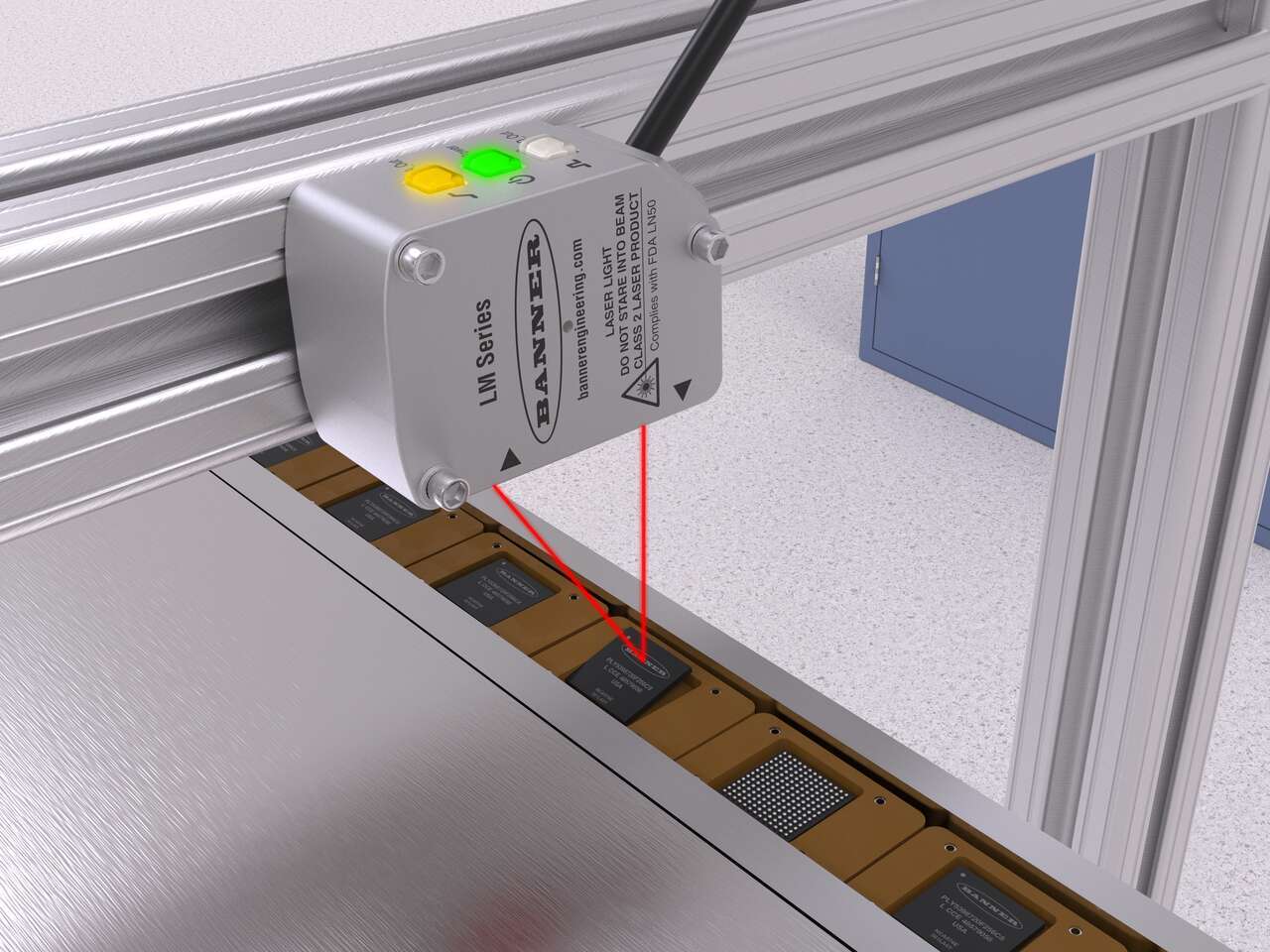

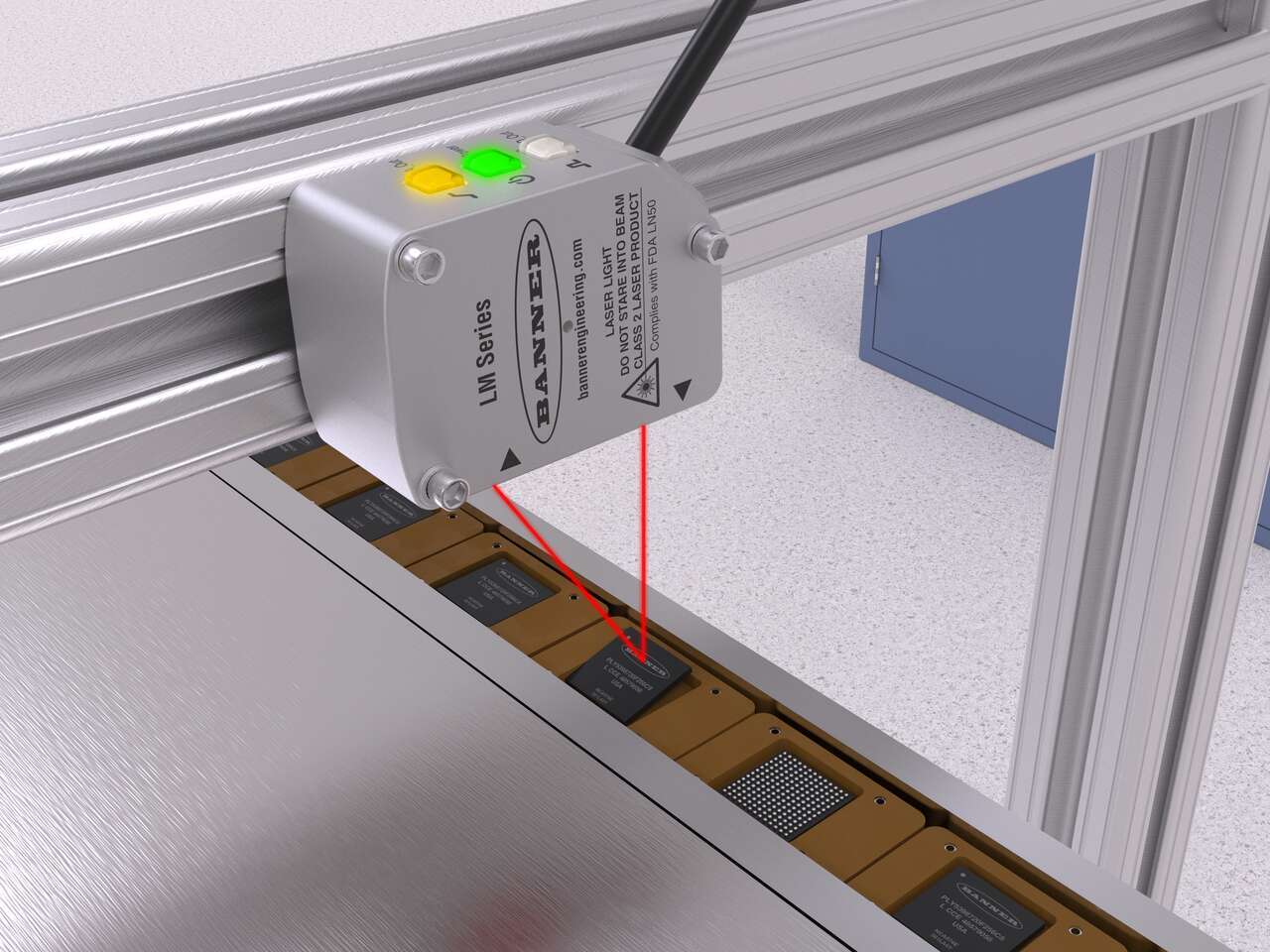

The LM Series precision measurement sensor from Banner Engineering offers best-in-class performance with superior stability, reliability, and precision for real world targets.

Prevent Errors at the Source

Error proofing refers to preventing a process from resulting in defects by stopping mistakes at the source, rather than down the line. Preventing mistakes at the source can significantly improve productivity by keeping mistakes from becoming bigger problems downstream.

In automated processes, error proofing solutions like sensors and vision systems can be used to ensure poblems are corrected before a process can proceed.

Meanwhile, in manual processes, such as bin picking, visual warnings clearly indicate to operators when their actions are correct or incorrect using colored and/or animated lights. Light-guided assembly is an excellent example of using visual indication for error-proofing.

Precision Measurement Sensor

LM系列高精準度量測感測器提供同級最佳性能表現,能在實際應用中提供穩定的表現,並有著精巧的外型以及簡單易用的使用者體驗。

- 精準的量測能力,可 0.004毫米解析度

- 0.5 ms反應時間以及0.25 ms取樣速度

- 精巧的外型可以安裝在狹小的空間之中

- 優異的熱穩定外殼以及穩固的安裝孔位,可以在實際應用中提供穩定的性能表現

- 數位輸出帶IO-Link通訊以及4-20 mA電流類比輸出

- IP67以及316不鏽鋼外殼,可以抵禦特定化學侵蝕環境

- 選配的 遠端感測器螢幕 可以自機台外部監控及設定感測器

iVu Series

Vision Sensor

iVu和iVu顏色圖像感測器用於監測部件的類型、尺寸、方向、形狀、位置以及顏色或顏色變化。

- 一體式的設計包含了視覺感測器、控制器、鏡頭以及燈源。

- 使用Vision Manager PC軟體、機載觸控式螢幕或遠程觸控式螢幕可在幾分鐘內完成配置

- 多樣的灰階及色彩工具可同時進行多點檢測

- 輕薄、堅固、IP67級外殼配有集成式環形燈,顏色可變為紅色、藍色、綠色、白色、紅外或紫外線

- 可更換鏡頭,配有C型支架,可最大限度地提高應用靈活性

- EtherNet/IP™、 Modbus/TCP、PROFINET®、PCCC、 和串列RS-232

![用於檢測液體藥物的LED燈[成功案例分享]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![工業捲線機零缺陷標準[成功案例分享]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)