所有物料處理解決方案

-

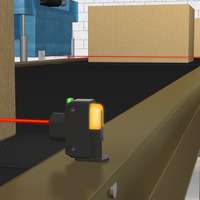

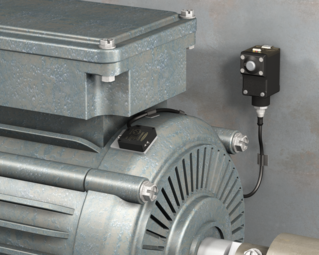

Motor Temperature Monitoring and Control with a Wireless Network

Motor Temperature Monitoring and Control with a Wireless Network

Instead of installing I/O transmission cabling, use a 10 to 30V dc powered SureCross Node and a Banner T-GAGE temperature sensor. When using host control systems, the SureCross Gateway transmits the temperature to the plant control room using a digital output related to temperature setpoints within the sensor. The motor is powered down or up based on these temperatures. When using a Gateway Pro as the wireless master device, the data ca be logged and alerts sent out to notify maintenance personnel when a motor is performing outside expected parameters.

-

Controlling Temperature and Humidity for a Cabinet Maker

Controlling Temperature and Humidity for a Cabinet Maker

A large cabinet maker needs to monitor and control the temperature and humidity throughout many rooms in a large production facility. Manual environmental readings of the entire plant were conducted periodically throughout the week. These manual readings only provided a snapshot of information and gathering the data took more than three hours. The customer did not have real-time, accurate information that could be used to control the plant environment. Manually collecting this information and controlling the fan system was timeconsuming and resulted in errors that damaged wood in storage, work in progress, and finished cabinets.

-

機器監控/整體設備效能

機器監控/整體設備效能

• Expand available data beyond local indication • Gather information necessary to react quickly • Drive efficiency improvements based on data previously unavailable

-

Equipment Monitoring from a Supervisor's Station

Equipment Monitoring from a Supervisor's Station

• Provide at-a-glance machine status indication • Send machine status information to a wide range of devices • Alert staff and supervisors of critical conditions via text message or email

-

Environmental Monitoring inside a Machine Control Panel

Environmental Monitoring inside a Machine Control Panel

• Identify small problems before they become major issues that impact machine performance and uptime • Access environmental data from a remote location • Notify operators of critical conditions via text message or email

-

為預測和預防性的維護進行狀態監控

為預測和預防性的維護進行狀態監控

Identify machine problems before they cause serious damage or unplanned downtime and alert staff of changes in condition via text message or email as well as provide at-a-glance local indication of machine status.

-

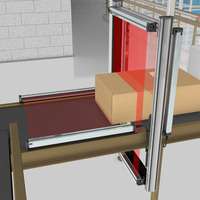

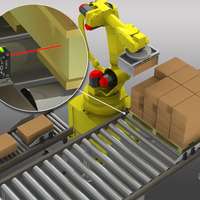

High Speed Package Profiling with Laser Sensors

High Speed Package Profiling with Laser Sensors

3 Apr 2019A laser measurement solution enables high-speed package sorting in order fulfillment applications and helps drives failure rates down—ultimately saving costs and maximizing profits.

-

Safeguarding Access Points to a Depalletizer

Safeguarding Access Points to a Depalletizer

An LS Series safety light curtain with a mute arm kit in T-configuration combined with an XS26 Series safety controller is an easy-to-implement solution that protects staff from potential hazards without disrupting the flow of pallets to the depalletizer.

-

棧板輸送帶的安全防護

棧板輸送帶的安全防護

Pallet transfer conveyors are used to move heavy loads to the shipping area. Both the pallets and the conveyor pose risks for accident and injury and must be safeguarded. An SX5-B safety laser scanners safeguards the loading and unloading stations on the conveyor and enables a continuous flow of pallets through the system.

-

條碼讀取

條碼讀取

ABR Series barcode readers can be used to solve track and trace applications, offering increased resolution to read smaller codes, over a larger target area, and at greater distances. Polarization is now available in both 1.3 MP and 2 MP ABR 7000 models for improved performance on targets with reflective surfaces or where glare is present. Our highest resolution camera, the VE is also available in only-barcode reading models, as well as the original vision camera-only model. This makes our VE series is the highest-resolution barcode reader in our portfolio, designed to better solve complex applications.

-

讀取多個一維和二維條碼

讀取多個一維和二維條碼

Barcode position can change with the location of each box on a conveyor and the height of the boxes can vary. An ABR 7000 barcode reader decodes multiple 1D and 2D barcodes over a large area in a single inspection, regardless of position or orientation.

-

準備訂單交貨:寬貨架

準備訂單交貨:寬貨架

每個寬貨架都配備了一個一體式的EZ-LIGHT PVD拾取指示燈感測器(採用反射板式),其工作距離可達2 m。PVD點亮一個箱子,工人將從此箱子中選擇要寄送的地圖。

-

為履行訂單而進行的箱子拾取

為履行訂單而進行的箱子拾取

在書籍包裝倉庫中,每個紙箱上方的貨架配有一體式EZ-LIGHT PVD拾取燈感測器。工人透過挑選裝箱單上指定的每類書的數量來取料以滿足ˋ訂單。為了使工人更容易找到從中挑選書籍的紙箱,這些紙箱上面特定的PVD會被點亮。PVD偵測工人的手位於紙箱中,以驗證書籍已經拾取。

-

大型工作站的光導引套組

大型工作站的光導引套組

Manual kit building at large stations can be time-consuming and subject to human error, especially if storage racks are difficult to navigate. The PTL110 series pick-to-lights are scalable for large systems and highly versatile to complete numerous tasks.

-

拾取指示燈可加快最終組裝和訂單出貨的速度

拾取指示燈可加快最終組裝和訂單出貨的速度

Learn how a golf equipment manufacturer recently used PTL110 pick-to-light devices to simplify and accelerate their final product assembly and order fulfillment processes.

-

利用拾取指示燈系統提高產量

利用拾取指示燈系統提高產量

了解eFlex Systems如何透過其總控制平臺和Banner的PTL110拾取指示燈為液壓泵製造商提供產品支持,進而提高生產力並减少組裝產品過程中的錯誤。

-

用於工作站的高品質 LED 工作燈

用於工作站的高品質 LED 工作燈

Banner’s WLB32 Industrial Light Bar is ideal for workstations. With a Hi/Lo/Off switch, operators are able to control the lighting level and are able to switch the LED light bar off when they are done. The WLB32 provides workers high brightness with even light output and enables numerous tasks in a workstation, including working on a computer.

-

Highly Bright Illumination in Workstations

Highly Bright Illumination in Workstations

Banner’s WLS28 Work Light Strips with ON/OFF switches provide an energy-efficient solution for illuminating work areas and enclosure interiors with intense, long-lasting light. These LED lighting strips provide even, extremely bright illumination, and can easily fit in limited space setups. The work lights can be plugged into any local power source for simple operation.

-

Low-Bay LED Lighting

Low-Bay LED Lighting

The heavy-duty, energy-saving WLB92 from Banner Engineering provides an extremely bright lighting solution that provides consistent lighting across a warehouse. Since the LED factory light is so bright and gives a uniform output, fewer lights are needed in total, helping reduce the overall cost of lights and installation time.

-

堆高機LED發光指示燈

堆高機LED發光指示燈

The WLS27 Pro with discrete control and configured by Banner’s Pro Editor software is one of two new models of the WLS27 Pro series strip light. It now includes programmable RGBW LEDs for use in illumination, indication and inspection applications. Learn how the configurable WS27 Pro provided forklift guidance for warehouse operators.

-

自动工业门上的明亮LED指示燈

自动工业门上的明亮LED指示燈

Star Equipment uses Banner's WLS27 multicolor LED strip lights with EZ-STATUS™ with their automated industrial doors for safer, more efficient movement in the workplace.

-

輸送機系統上的操作訓示

輸送機系統上的操作訓示

Learn how a facility used the K30 Pro Touch Button to improve operator control and guidance.

-

Measuring Wear Patterns on Conveyor Belts [Success Story]

Measuring Wear Patterns on Conveyor Belts [Success Story]

Elevators, escalators and moving sidewalks are major investments in any facility’s infrastructure. This equipment is expected to operate safely and reliably for many years and with minimal downtime for maintenance. To meet these expectations, a large-scale manufacturer of vertical and conveyor transport equipment performs rigorous tests on all system components. The data that is collected helps the company estimate component life expectancy and plan service schedules.

-

Long-Range Position Detection

Long-Range Position Detection

In a warehouse, the time-of-flight L-GAGE LT7 laser sensor gauges the position of a retrieval shuttle as far as 250 m away from the sensor.

-

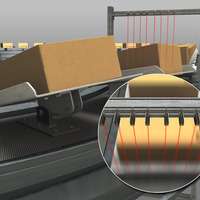

詳細檢測分揀輸送帶

詳細檢測分揀輸送帶

In large distribution facilities, sortation trays deliver products to the proper bin for correct shipment. Before sorting can begin, each tray needs to be empty so that items can be placed on the conveyor and sent to the next location. The 5mp VE Smart Camera recognizes very fine levels of detail and can detect items of almost any size, confirming the presence or absence of items on the trays.

-

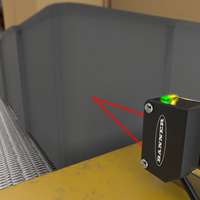

利用指示燈偵測仓库车辆

利用指示燈偵測仓库车辆

Vehicle detection at loading docks is complicated because sensing solutions are exposed to the elements and need to recognize a wide variety of surfaces. Rugged ultrasonic sensors work well to accurately detect the surfaces of delivery vehicles regardless of the material. Pairing with bright LED indication creates unmistakable operator guidance.

-

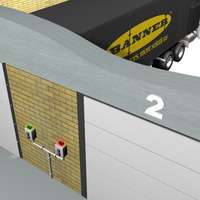

監控裝載區卡車的到達和離開

監控裝載區卡車的到達和離開

Sensor solution for outdoor truck detection for safety prevention purposes.

-

Inbound and Outbound Status Indication at Loading Dock

Inbound and Outbound Status Indication at Loading Dock

In a recent material handling application, facility managers needed to find a solution that would alert them to the status of trailer capacity at loading dock doors in real-time.

-

輸送帶上的緊急停止按鈕

輸送帶上的緊急停止按鈕

Banner的30 mm底座E-Stop按鈕在這種應用中工作良好,因為它們有一個照明基座,在啟動時由黃色變成閃爍的紅色。E-stop按鈕的紅色閃爍照明可以明顯地提醒操作人員按下哪個按鈕,以便他們可以快速方便地解決問題、減少停機時間,並且只重置激活的按鈕。

-

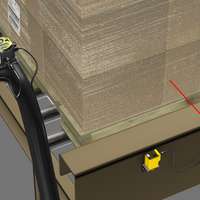

偵測具有不規則載入的棧板

偵測具有不規則載入的棧板

超音波感測器將提供可靠的棧板偵測。超音波感測器發出音波,並「偵聽」從目標物反彈回的音波。可以教導感測器可靠的背景,在本例下是輸送帶,並偵聽從輸送帶返回的音波。進入感測器與輸送帶之間的任何物件都將被檢測到,導致輸出切換。

-

自動儲存和拾取系統

自動儲存和拾取系統

SureCross FlexPower™節點和低功率感測器相結合,創建一個便攜式監控系統,可立即與現有的儲存和拾取系統(AS/RS)起重機整合。Banner的可靠無線解決方案與獨特的電源管理功能的組合在AS/RS起重機上創建了大量簡化的監控應用。FlexPower電池組為節點和多達四個低功率感測器供電,可令其運行多年。可以透過一個配備多個熱電偶(用於監控電機或關鍵軸承溫度)的FlexPower節點來解決預防性維護問題。閘道(系統控制器)上的通訊輸出可用於創建歷史記錄或趨勢,以驗證設備是否以最佳性能運行。可以利用每個通道的末端的EZ-LIGHT™指示燈來通知工作人員起重機正在運動。這種雙向監控系統是一種提醒員工起重機正在運動的簡便方式,無需任何新的結構或代價高昂的停機。

-

偵測交流供電輸送帶上的物品

偵測交流供電輸送帶上的物品

WORLD-BEAM QS18通用電壓感測器可以連接到交流或直流電源,這使得它們可以在已經使用交流電源的大型輸送帶應用中運行,而不需要單獨的電源。堅固,精巧的外殼和多種安裝選項增加了WORLD-BEAM QS18通用電壓感測器的多用性。

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Motors and Gearboxes on Large Cranes [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-In-A-Port-49071524.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Rotating Parts on Conveyor [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Thermal Remediation Temperature Measurement [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Detecting Various Registration Marks [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/R58_roll_closeup.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Simplifying Safety Feature Management [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Algus_MKuhlow.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![LED Light Bars Outshine Fluorescents, Reduce Machine Build Times & Expenses [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/WLB32%20Muti-Station%20Test%20Workstation%20Illumination%20(High_Res_PSD).psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Long-Lasting LEDs Install Quickly to Illuminate Web Inspection Stations [Success Story]](/content/dam/banner-engineering/photography/success-story-photography/WLB32-LED-Lights-Web-Inspection.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Status Indication on Driverless Vehicles [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Accurately Measuring Bakery Ingredients [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Inspecting Small Connectors [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![工業捲線機零缺陷標準[成功案例分享]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![用於檢測液體藥物的LED燈[成功案例分享]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![充填機上氣管識別有無[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![在緊急情況下測量出車時間[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/R-GAGE-Vehicle-Detection---Firehouse.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Measuring Wear Patterns on Conveyor Belts [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LH-Elevator-Belt-Inspection.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)