汽車業成功案例

-

Temperature Sensor Detects Defrost Wires [Success Story]

Temperature Sensor Detects Defrost Wires [Success Story]

An automotive manufacturer was rejecting a supplier’s shipment of rear window assemblies due to faulty defroster grids. The supplier’s existing test procedure measured current draw across the entire heating system to detect an overall failure, but it could not detect the subtle impact of a single heating wire being broken. The window supplier partnered with a Michigan-based machine automation company to create a better test fixture—one that can verify each defrost wire heats to specification prior to shipping.

-

Status Indication on Driverless Vehicles [Success Story]

Status Indication on Driverless Vehicles [Success Story]

The K50L domed 50 mm indicator light works well for status indication on autonomous shuttle buses. The buses operate on short distances in outdoor environments that exposed the bus technology to a variety of weather conditions. The rugged K50L indicators are rated IP67 and IP69K to withstand water ingress in the harsh environment.

-

可追溯性紫外光條碼

可追溯性紫外光條碼

Before shipping to the brand assembler, a supplier of auto visors needs to verify that Data Matrix UV barcodes have been printed on each visor’s safety label. The customer turned to Banner to read invisible 2D Data Matrix barcode and send data via Ethernet IP to a PLC for traceability/error proofing.

-

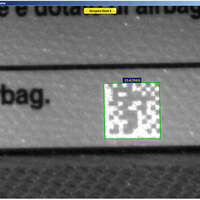

視覺感測器讀取 QR 碼

視覺感測器讀取 QR 碼

iVu Plus BCR Gen 2 with 25 mm Micro Lens replaces hand held barcode readers to collect data from dense, difficult-to-read QR codes on vehicle transmissions. A WL50S high-intensity LED spot light illuminates the target area.

-

操作指導解決方案

操作指導解決方案

A Henshaw customer manufactures drivetrain and powertrain systems for the automotive industry. The company had experienced productivity losses due to errors in the assembly of transmission valve bodies. Henshaw was tasked with developing a system that would reduce errors and improve the assembly process.

-

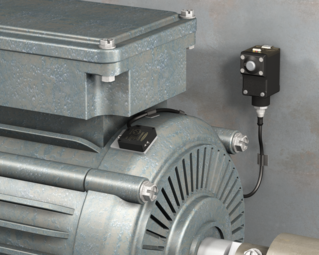

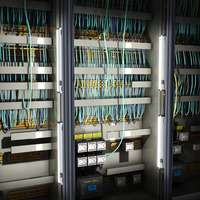

LED Lights Illuminate Control Cabinet

LED Lights Illuminate Control Cabinet

An equipment manufacturer builds test and measurement machinery for the auto industry. Operators access machine systems through the control cabinet. Intense illumination of the cabinet facilitates machine maintenance and management. Multiple AC powered fluorescent light fixtures had been used for this task.

-

Superior Light Distribution with LEDs [Success Story]

Superior Light Distribution with LEDs [Success Story]

American Hoffmann Corporation chose WLB32 LED light bars to illuminate work areas, enclosures and control cabinets, replacing fluorescent light fixtures. The superior light distribution offered by the WLB32 LED lights lights, as well as the ease of installation were key factors in the company's decision.

-

Inspecting Small Connectors [Success Story]

Inspecting Small Connectors [Success Story]

An automotive supply company makes a range of vehicle systems. Their seating systems combine structure and design with features that enhance comfort and safety. Weight sensors installed on the underside of the seats work in coordination with vehicle safety systems to determine the size and position of a seat occupant. These factors affect how or if airbags will be deployed in the event of an accident.

-

Sensors to Measure Movement Range

Sensors to Measure Movement Range

During assembly, inspections are conducted to measure seat height adjustment, forward and rearward movement, and upright and recline motion. Two sensors are used for each inspection. The sensors are deployed off the conveyor line to ensure easy access to and the free movement of the seats. At its maximum range during inspection, a seat may be as far as a meter away from the sensors.

-

Run Bar提供操作人員指示

Run Bar提供操作人員指示

A leading machine manufacturer builds workstations designed for accurate, timely and cost-effective battery cell assembly. A value added component of the workstations is an operator guidance device that does three jobs: enables assembly processes to start and stop, indicates parts to be picked and installed, and completely stops line operation if emergencies occur. When it became too costly for the OEM to construct and mount these devices themselves, they turned to Banner to craft an all-inclusive solution. To honor the time line requirements of their customer—a major tier two battery supplier—the OEM needed the solution in eight weeks.

-

工業捲線機零缺陷標準[成功案例分享]

工業捲線機零缺陷標準[成功案例分享]

一家成功的特種工業紗線製造商為汽車、航空航天、軍事和復合材料行業製造玻璃纖維和玻璃絲線產品。為了保持高標準并盡可能降低產品回報,他們建立了零產品缺陷的目標。為了實現這一目標,公司需要一個自動化絲線檢測系統。

-

偵測從模具彈出的零部件[成功案例]

偵測從模具彈出的零部件[成功案例]

在製造商的設施中,操作人員手動從模具中插入和移除金屬零部件。在完成後,零部件透過金屬滑槽送入一個箱子。為了防止模具碰撞(在壓機中同時有兩個零部件),客戶需要一個感測器,可以偵測滑槽上的各個零部件,並向控制系統發送一個訊號,表明壓機已經空閑,並允許操作人員執行下一個衝程。需要安裝一個解決方案:無需在滑槽側部的切割槽中或滑槽末端安裝感測器,因為這樣做可能會為行進的零部件產生绊点。

-

繁忙製造地點中的通訊 [成功案例]

繁忙製造地點中的通訊 [成功案例]

隨著更多的組件通過烤箱,與待卸載物品的流動保持同步變得越來越困難。分揀區逐漸變得擁堵。物品容易被引導至錯誤方向或甚至損壞。零部件流動的暫停使得卸貨操作人員可以糾正錯誤並令取貨站保持通暢。不過,卸貨和裝貨區之間的距離以及周圍機器的環境干擾使操作人員之間的通訊變得複雜。

![Vibration Monitoring a Main Air Handler [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/predictive-maint/qm30vt-motor-vibration-detection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Motors and Gearboxes on Large Cranes [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/bigstock-In-A-Port-49071524.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Predictive Maintenance of Rotating Parts on Conveyor [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_111970609.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Thermal Remediation Temperature Measurement [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/SURE-CROSS-Flex-Power-w-RTD---Temp-Measure-in-Flour-Mill.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Detecting Various Registration Marks [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/R58_roll_closeup.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Simplifying Safety Feature Management [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Algus_MKuhlow.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![LED Light Bars Outshine Fluorescents, Reduce Machine Build Times & Expenses [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/WLB32%20Muti-Station%20Test%20Workstation%20Illumination%20(High_Res_PSD).psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Long-Lasting LEDs Install Quickly to Illuminate Web Inspection Stations [Success Story]](/content/dam/banner-engineering/photography/success-story-photography/WLB32-LED-Lights-Web-Inspection.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Status Indication on Driverless Vehicles [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Accurately Measuring Bakery Ingredients [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/dropbox3.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Inspecting Small Connectors [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![工業捲線機零缺陷標準[成功案例分享]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![用於檢測液體藥物的LED燈[成功案例分享]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2011/WLA-IV-Bag-Manual-Inspection---Particulates.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![充填機上氣管識別有無[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-C-Mount-Remote-washer-Tube-Inspection.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![在緊急情況下測量出車時間[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/R-GAGE-Vehicle-Detection---Firehouse.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![Temperature Sensor Detects Defrost Wires [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2012/T-GAGE-Defrost-Wire-Inspection.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Status Indication on Driverless Vehicles [Success Story]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Superior Light Distribution with LEDs [Success Story]](/content/dam/banner-engineering/photography/application-photos/miscellaneous/hofmann_enclosures_wlb32.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![Inspecting Small Connectors [Success Story]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/LE550-Vehicle-Seat-Weight-Sensor-Connector.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![工業捲線機零缺陷標準[成功案例分享]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/Fotolia_51604759_M.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![購物中心將車輛引導至有空位的停車場[成功案例]](/content/dam/banner-engineering/photography/general---stock-photography/valueprop/edited/wcc-migration/2015/kiosks_alt.jpg/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![偵測從模具彈出的零部件[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2012/PVD-Part-Out.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)

![繁忙製造地點中的通訊 [成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2014/K50-Touch-and-TL50---Industrial-Oven_For-Andrew.psd/jcr:content/renditions/cq5dam.web.200.200.jpeg)