Track and Trace for Product Recall

Mitigate Damages with Accurate, Timely Recalls

An important goal for any manufacturer is to avoid product recall. Recalls are costly, in terms of both actual costs of repair, replacement, or buy-backs as well as the cost of a tarnished brand reputation.

Implementing quality control solutions can help reduce the risk of product defects and safety hazards; however, even the most effective quality control does not eliminate all risk.

Recalls happen, and when they do, it is critical that manufacturers are prepared to respond quickly by identifying affected products and issuing a timely recall to mitigate damages.

When recalls occur, a manufacturer's response can make or break its reputation, and by extension, impact customer loyalty and future profits.

Manufacturers must act quickly and recall all affected products that have already been purchased. In some cases, manufacturers must be able to quickly pull affected inventory from their own shelves, distribution centers, and retail establishments. In other instances, like in many automotive recalls, consumers may need their purchases repaired in a timely manner. Furthermore, to prevent unnecessary costs, manufacturers must avoid inadvertently recalling unaffected products.

Track and trace solutions help manufacturers execute recalls quickly and accurately, so that affected products can be repaired or removed from the market, and the issue can be resolved quickly.

These solutions depend on reliable identification of individual products throughout the supply chain—most commonly by scanning barcodes at every stage from production to purchase. Track and trace solutions are only as reliable as the devices that scan the codes, so selecting the appropriate identification technology is critical.

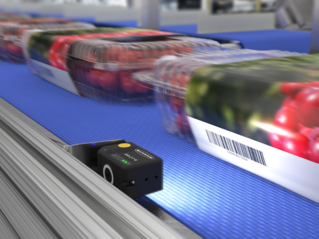

Track and Trace for Food Safety

- In food packaging, barcodes are embedded with information specific to each product and production run in order to identify products throughout the supply chain.

- As part of a track and trace program, a packing house verifies product barcodes at multiple points during packaging, creating a record that will allow the company to quickly identify and isolate any product with quality issues in the event of a recall.

- Imager-based barcode readers, like the ABR 3000 from Banner, are capable of decoding the widest range of 1D and 2D barcodes. Deployed along the packaging line, the ABR 3000 verifies that the barcode printed on each package is present, readable, and correct for each production run.

- The information contained in the barcodes is sent via an Ethernet connection to the company’s production management system which records the data for future referrence.

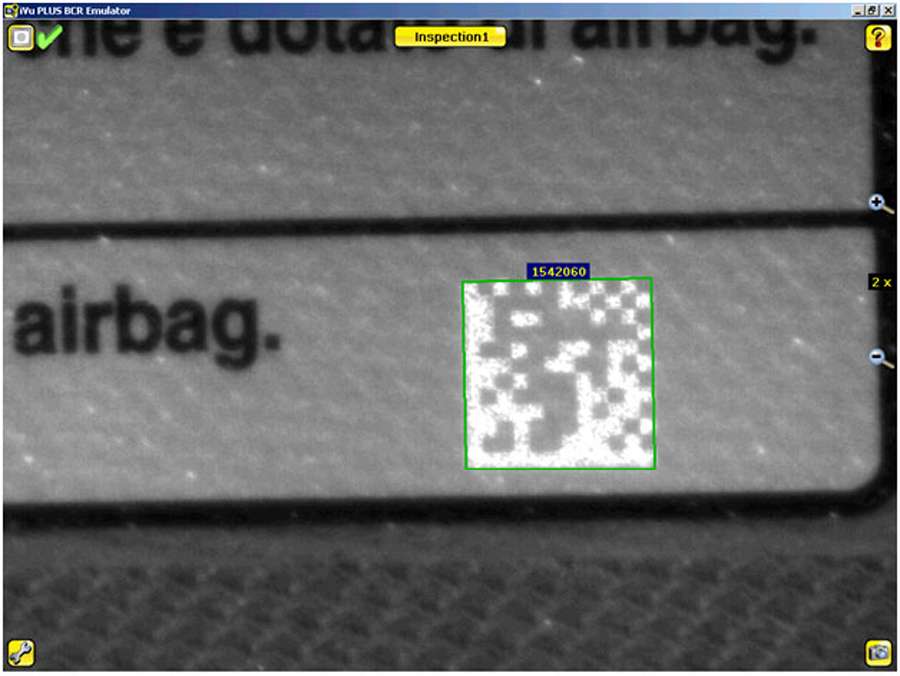

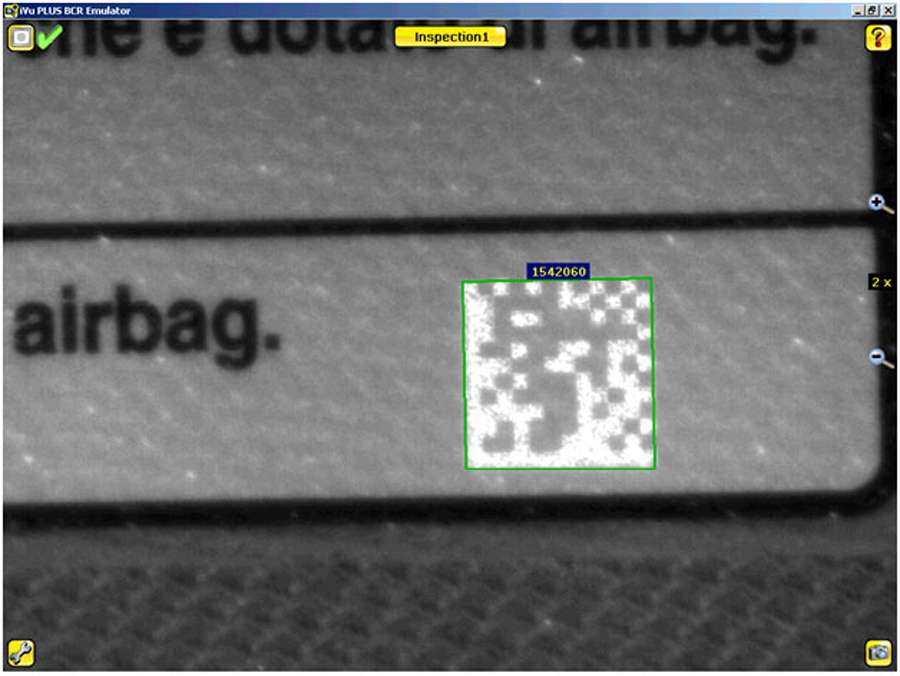

Track and Trace for Automotive Components

- Many automotive suppliers are incorporating Ultra Violet (UV) barcodes for component traceability and quality control.

- The technology uses UV-based ink that is only visible to the human eye when illuminated with a UV light source. Suppliers can store key informationin a small code printed directly on the component, without affecting design or aesthetics.

- In the event of a recall, codes can be scanned to verify that components were installed and tested in compliance with standards.

- In this application, an iVu BCR barcode reader with a C-mount lens, UV spotlight, and Ethernet capabilities can be used to read invisible 2D Data Matrix codes and send data via EtherNet/IP to a PLC for error proofing and traceability.

Track and Trace for Pharmaceutical Packaging

- Traceability is only effective for facilitating recalls if the correct codes are attached to the correct products. Therefore, validating codes prior to shipment is critical.

- In the pharmaceutical industry, medical supplies are often individually packaged in sealed pouches.

- Before product can be shipped, the barcodes must be validated to ensure that the correct barcode is affixed to the correct product for accurate traceability.

- An imager-based barcode reader validates each barcode and sends data via Ethernet IP to a PLC for future reference in case of recalls.

Imager-Based 1D and 2D Barcode Reader

Üstün kod okuma yeteneğine sahip ABR Serisi barkod okuyucular ile izlenebilirlik uygulamalarınızın kolaylıkla üstesinden gelebilirsiniz. İki farklı kompakt tasarıma sahip gövdesinde birden fazla ışık, çözünürlük, mesafe ve ayrıca geniş lens yelpazesi sunar.

- En zorlu 1D ve 2D kodları okuyabilir.

- IP67 koruma sınıfına sahip gövdesiyle endüstriyel ortamlarda kullanıma uygundur.

- 2MP'e varan çözünürlük, çeşitli aydınlatma ve odak uzunluğu seçenekleri (otofokus dahil) ve birden fazla okuyucuyu birbirine bağlayabilme gibi gelişmiş özellikler sunar.

- DPM kod okuyan modelleri mevcuttur.

- Üzerinde bulunan butonlarla veya Barcode Manager yazılımı ile dakikalar içerisinde programlanabilir.

- Fonksiyonel lens seçenekleri ile kurulum ve konfigürasyonu oldukça kolaydır.

- Ethernet, Serial ve USB gibi endüstriyel haberleşme protokollerine sahiptir.

- Web server özelliği sayesinde, kontrol edilen görüntü ve kontrollerin istatiksel sonuçlarını sistemin bağlı olduğu ağ üzerindeki herhangi bir noktadan izleyebilirsiniz.

Imager-Based 1D and 2D Barcode Reader

Üstün kod okuma yeteneğine sahip iVu BCR Serisi en zorlu izlenebilirlik uygulamalarınıza kullanımı kolay çözümler sunar. Fonksiyonel barkod okuyucuların geniş yelpazede lens, ışık ve kullanıcı arayüzü seçenekleri mevcuttur.

- Okunması zor ve hasar görmüş barkodlar dahil olmak üzere 1D ve 2D barkodları okuyabilir.

- Tek bir denetim özelliğiyle birden fazla barkodu yönden bağımsız olarak okuyabilir.

- Dahili ekran, harici ekran ya da PC aracılığı ile programlayabilirsiniz.

- Ethernet, Serial ve USB gibi endüstriyel haberleşme protokolleriyle Endüstri 4.0 uygulamalarında kullanım için idealdir.

- IP67 koruma sınıfına sahip iVu Serisini endüstriyel ortamlarda güvenle kullanabilirsiniz.

- Dahili aydınlatma seçenekleri sayesinde daha iyi kontrast elde etmenize yardımcı olur.

- Standart veya C-Mount değiştirilebilir lensleri uygulamada maksimum esneklik sağlar.

TCNM Series

Laser-Based 1D Barcode Scanner

Endüstride en çok tercih edilen tüm lineer barkodların algılanmasında kullanılabilen TCNM Serisi barkod tarayıcı yüksek okuma hızına, geniş tarama derinliğine ve yüksek çözünürlüğe sahiptir.

- Endüstride en çok kullanılan lineer barkodları algılar

- Saniyede 500 ile 1000 adet tarama gerçekleştirilebilir

- Smart Teach butonu ve LED indikatörleri ile kolay kurulum ve kullanım imkanı sunar

- Özel algoritması sayesinde, hasarlı barkodları başarıyla okur

- GeniusPlus yazılımı ile konfigüre edilir

- Multi-head ağ ile birden fazla tarayıcıyı tek bir uygulamada birbirine bağlayabilirsiniz

- Sağlam, IP65 koruma sınıfına sahiptir