Pick-to-Light Accelerates Final Assembly & Order Fulfillment

Light-Guided Picking for General Manufacturing

While some users associate pick-to-light technology with large automotive manufacturing applications, pick-to-light systems also improve quality and increase efficiency in general manufacturing facilities with high product mix. Keep reading to learn how a golf equipment manufacturer recently used PTL110 pick-to-light devices to simplify and accelerate their final product assembly and order fulfillment processes.

In a recent pick-to-light application, a golf equipment manufacturer was looking for a way to improve the process of picking equipment components to assemble final product and fulfill customer orders.

Fully manual picking was slow and prone to error. The many different components were challenging to quickly distinguish from one another visually, and workers struggled to keep up a fast pace without sacrificing quality.

As a recognized and respected brand, the manufacturer needed to meet its customer’s high expectations. Slow delivery times and incorrect orders were unacceptable and could damage the brand’s reputation and reduce repeat or referral business.

A solution was needed to help assemblers quickly and accurately pick golf equipment components to ensure customers received the correct order in a timely manner.

Learn More about the Benefits of Pick-To-Light for Order Fulfillment

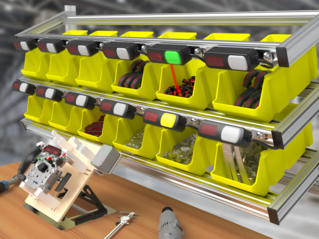

The golf equipment manufacturer worked with a local integrator to create a powerful pick-to-light system using Banner’s PTL110 pick-to-light devices mounted below each bin containing different components.

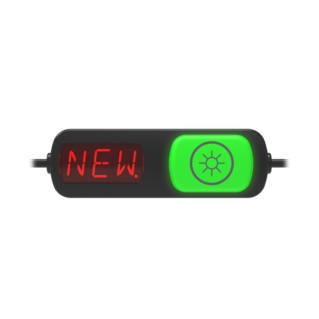

The picking system for this application used several functions of the PTL110 devices to enable faster, more accurate picks:

- Bright, colorful LED indicators guided workers to the right bin to pick the correct component,

- The on-board alphanumeric display indicated how many of each item to pick, and

- The optical sensing function confirmed correct picks in real time.

In addition, if an employee noticed that inventory was running low, they could push the touch button on the appropriate PTL110 device to call for more parts. This enabled workers to restock inventory quickly, reducing wait time and improving efficiency.

Together, this easy-to-understand picking system ensured that final product could be quickly assembled with the correct components and shipped out to the customer with confidence. The new solution resulted in fewer errors, faster shipping, and overall improved customer satisfaction.

Seamless Integration within Existing Infrastructure

PTL110 pick-to-light devices easily attach to the existing infrastructure of the order fulfillment rack with a variety of brackets or standard cable ties. Each PTL110 device has two M12 connectors for quick and secure installation of multiple devices with no additional cables required. Devices can be quickly moved and replaced with no tools, rewiring or reprogramming required.

Fast Implementation and Results

PTL110 pick-to-light devices are powered by PICK-IQ™, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that results from polling multiple devices. The high response speed at scale makes PTL110 an ideal solution for assembly lines and fulfillment stations that require many pick points while maintaining a rapid pace. The speed and functionality of PICK-IQ also translate to faster implementation, lower project cost, and quicker results.