Leading Edge Detection

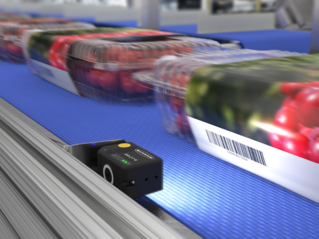

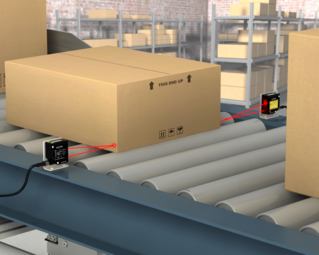

On equipment that moves a product, container, or package, sensors are used to detect the movement or presence of these items to make critical decisions. Specifically, these applications rely on detecting the leading edge of the item as quickly and as accurately as possible.

Banner has developed multiple innovative sensors that address the ability to detect very thin or irregular objects on conveyors with reduced installation time and cost. When an object on a conveyor blocks any of the beams, the sensor indicates that a package is detected and accounted for. Banner offers a several proven leading-edge detection solution to meet any application.

Challenges of Leading Edge Detection

Types of Containers / Packaging

Trends in packaging have migrated from boxes to more challenging targets. Polybags, Blister packs, envelopes, totes, and tubes are commonly transported on conveyor lines and can have irregular shapes. As a result, sensing solutions need to be adapted to reliably detect a product.

Types of Conveyors / Equipment

There are many different types of conveyors and machines used to move goods. Some machines can use certain types of sensors while others may not.

The Q76E is a problem-solving sensor that detects the leading edge of challenging, non-uniform targets. It features two sensitivity levels for detection of challenging targets such as small objects, shrink-wrapped objects, and film or perforated packaging. Easy to setup and use, the Q76E has a visible red beam to simplify alignment to the reflector and two bright, multifunction LED lights for status indication. The TEACH button adjusts sensor sensitivity and selects light operate or dark operate. With a range of up to 4-meters, the Q76E provides users with tremendous flexibility in deployment. The sensor is IP67, IP69 and Ecolab certified for use in washdown environments. The Q76E is available with IO-Link for simple device replacement, remote configuration, and increased data availability.

SAB Series Sensor Array Bar

Ideal for use on conveyors and chutes, the SAB sensor array bar fits multiple QS18 sensors in a robust aluminum housing for use on heavy-duty conveying and packaging lines. They can be made to meet specific customer needs. The length of the aluminum housing, number of sensors and sensor spacing can be customized depending on the application. The one-piece design provides simple installation with only one M12 connector to power all the sensors and consolidate individual outputs into one discrete output. The SAB is vibration resistant and prevents the sensors from shifting out of alignment.

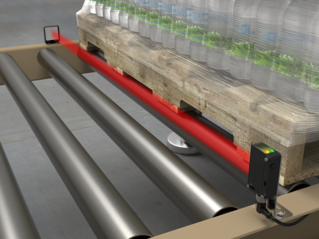

The TTR Series Through-the-Roller sensor is specifically designed for ease of installation and reliable detection of objects on a roller conveyor. Its thin profile fits easily into the gap between roller conveyors and the patent-pending spring-loaded endcap design simplifies installation and alignment, reducing installation time by as much as 50% compared to conventional polarized retro sensors. Users can quickly install up to seven diffuse sensors across the width of a conveyor for reliable detection. The TTR is designed and tested to be resistant to ESD damage, a common challenge in dry climates when plastic rollers are used.

LX Series light screens have a large detection area to reliably detect irregular and extremely flat objects. The LX is available in lengths from 3" to 36" to provide consistent detection of packages where the leading edge varies. They work in emitter/receiver pairs that create a cross hatched beam pattern to detect objects as thin as 1 millimeter, depending on the width. The LX has response speeds as fast as 0.8ms that allows automated systems to operate at higher line speeds resulting in increased throughput.

QS18 and Q20 polarized retroreflective photoelectric sensors are cost-effective single sensing beam solutions sufficient for many targets, such as boxes and totes. They have excellent optical performance throughout the sensing range—even from up close. Polarization assures reliable detection of highly reflective packages. Retroreflective sensors are robust—almost as good as opposed mode—but do not require power on both sides of the conveyor, saving installation time. These sensors are typically used on conveyors with side rails for ease of installation and many brackets are available when side rails are not present.