Temperature and Humidity Monitoring in Coolers

Challenge

In the food and beverage manufacturing industry, maintaining the proper temperature and humidity in coolers is critical to preserving product quality and reducing waste due to spoilage. However, monitoring these conditions manually can be time-consuming and prone to error, leading to inefficiencies and potentially significant product loss.

Solution

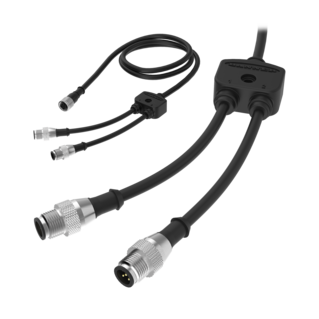

To address this problem, Banner’s condition-monitoring temperature and humidity wireless sensor can be mounted in a cooler to provide real-time data on the temperature and humidity levels. The sensor is wireless, making it easy to install and move as needed. It also has a long battery life and can be configured to send alerts when readings fall outside of pre-set thresholds. There is also a wired version of this solution as shown on the next page which can offer more frequent readings from the sensor.

Benefits

- Reduce product waste: By continuously monitoring the temperature and humidity levels, the risk of spoilage and product waste is reduced.

- Improve efficiency: Sensors eliminate the need for manual monitoring, saving time and reducing the risk of error.

- Collect real-time data: The sensor provides real-time data on temperature and humidity levels, allowing for immediate action to be taken if readings fall outside of the pre-set thresholds.

- Receive customizable alerts: The sensor can be configured to send alerts via Banner Cloud Data Services when readings fall outside of the pre-set thresholds, allowing for quick action to be taken to rectify any issues.