Pick and Place Machine Leading Edge Detection

Challenge

During the manufacturing of circuit boards, pick and place machines operate precisely and extremely fast. The first step occurs when solder paste is applied to a board with a soldering printer. SMT (surface-mount technology) components, typically consisting of resistors, diodes, transistors and integrated circuits, are loaded on a template to help guide components to the correct place.

In order for a complete, speedy process, reliable leading edge detection is needed for pick and place machine applications.

Solution

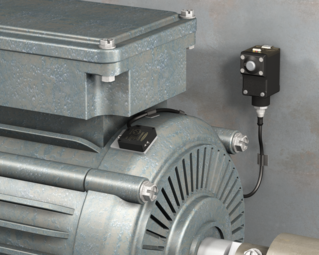

Fiber optics are an ideal solution for pick and place machines because of their small size. DF-G1 amplifiers can be separated from fibers so the operator has easy access to the digital dual-display screen for data monitoring.

Additionally, the cross talk avoidance algorithm allows two or more amplifiers to operate in close proximity to each other. With a minimal warm-up drift that allows for side-by-side mounting, DF-G1 amplifiers can easily be arranged in a line to sense the leading edge as SMT components are placed across the circuit board.

The DF-G1 uses a visible red LED sensing beam that makes alignment easy, reducing overall installation time. Simple operation and data monitoring are possible with an intuitive user interface, including switch point threshold, light operate or dark operate, output timing functions, gain level and response speed.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)