Machine Safeguarding in an ESD-Sensitive Environment

Application: Guarding a wafer carrier station

Challenges: ESD-sensitive area

Solution: ESD-safe EZ-SCREEN Safety Light Curtain

Benefits: Nickel-plated enclosure dissipates electrostatic discharges

Using safety light curtains to guard work cells is an effective and efficient alternative to hard guarding and access doors. When safeguarding in semiconductor wafer processes, special care and attention must also be considered to address problems associated with electrostatic discharge (ESD). Applying the right safety components enables safeguarding employees while protecting equipment and semiconductor product.

Description

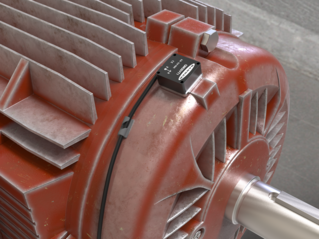

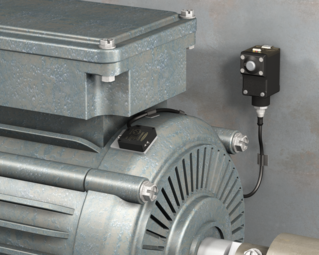

In this application, machine operators require access to the wafer carrier station. The EZ-SCREEN ESD safety light curtain system is configured to safeguard the process and operator using emitters, receivers and mirrors to enclose three sides of the station. Safety light curtains allow quicker, easier access than physical barriers while preventing machine movement if the operator reaches into the hazardous zone.

In addition, this application also calls for safety equipment that reduces the possibility of electrostatic discharges that could damage the product or interfere with the automation process. The EZ-SCREEN ESD safety light curtains have a special, nickel-plated enclosure to dissipate ESD. This ESD version of the EZ-SCREEN also has all the programming, setup and functionality of the standard version of the product family.

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)